COMMISSIONING

6 720 648 726 (2011/07)

52

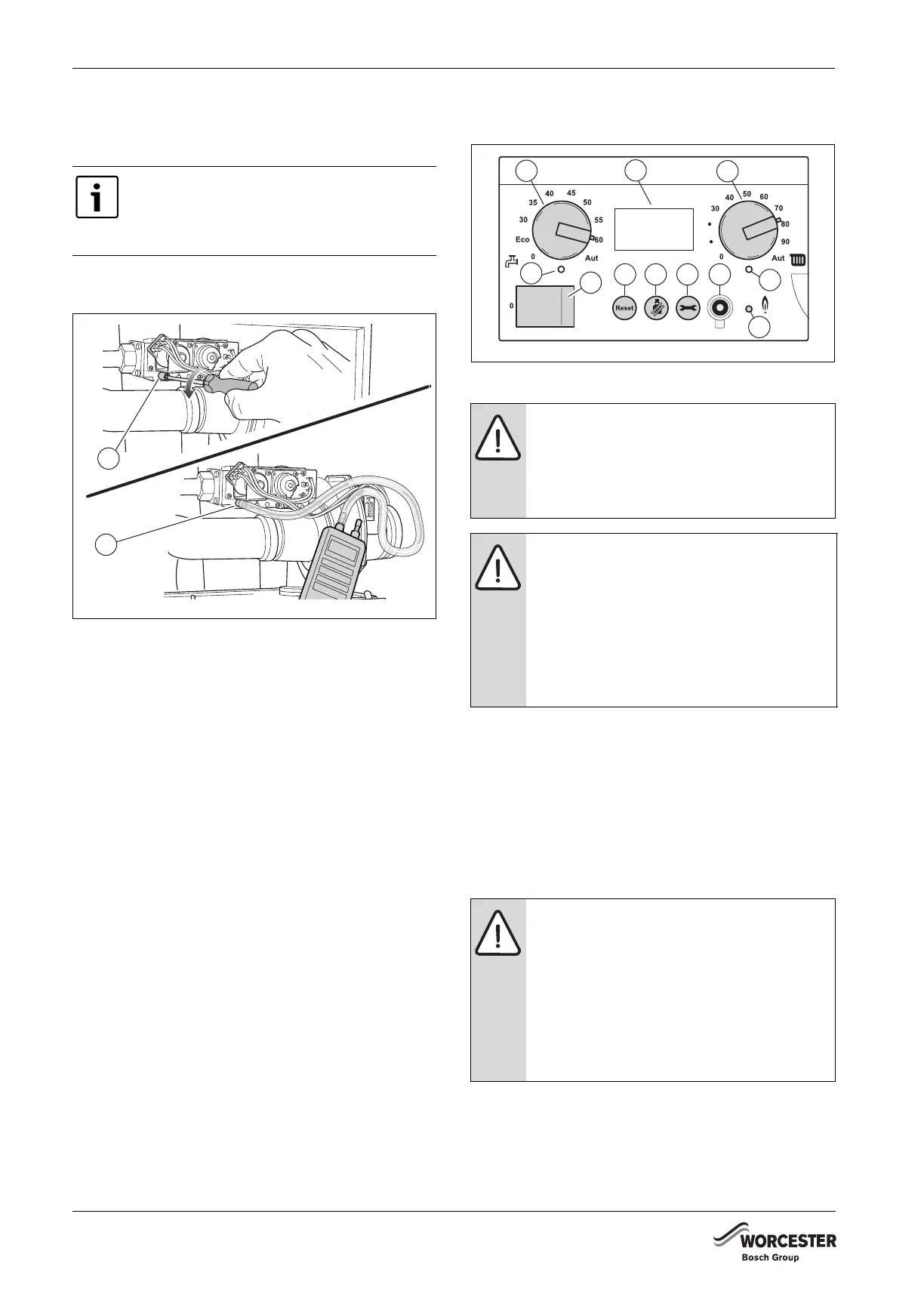

B Open the screw plug on the testing nipple for the gas

hook-up pressure and for purging by 2 turns [1].

B Reset the digital pressure gauge to "0".

B Connect the pressure gauge connection tube to the

positive port of the testing nipple [2].

Fig. 85 Measuring the gas supply pressure

B Slowly open the gas valve by pushing on the gas valve

and turning it ¼ rotation in an anticlockwise direction

(Æ fig. 79, page 49). The gas valve is open when it is

in the vertical position.

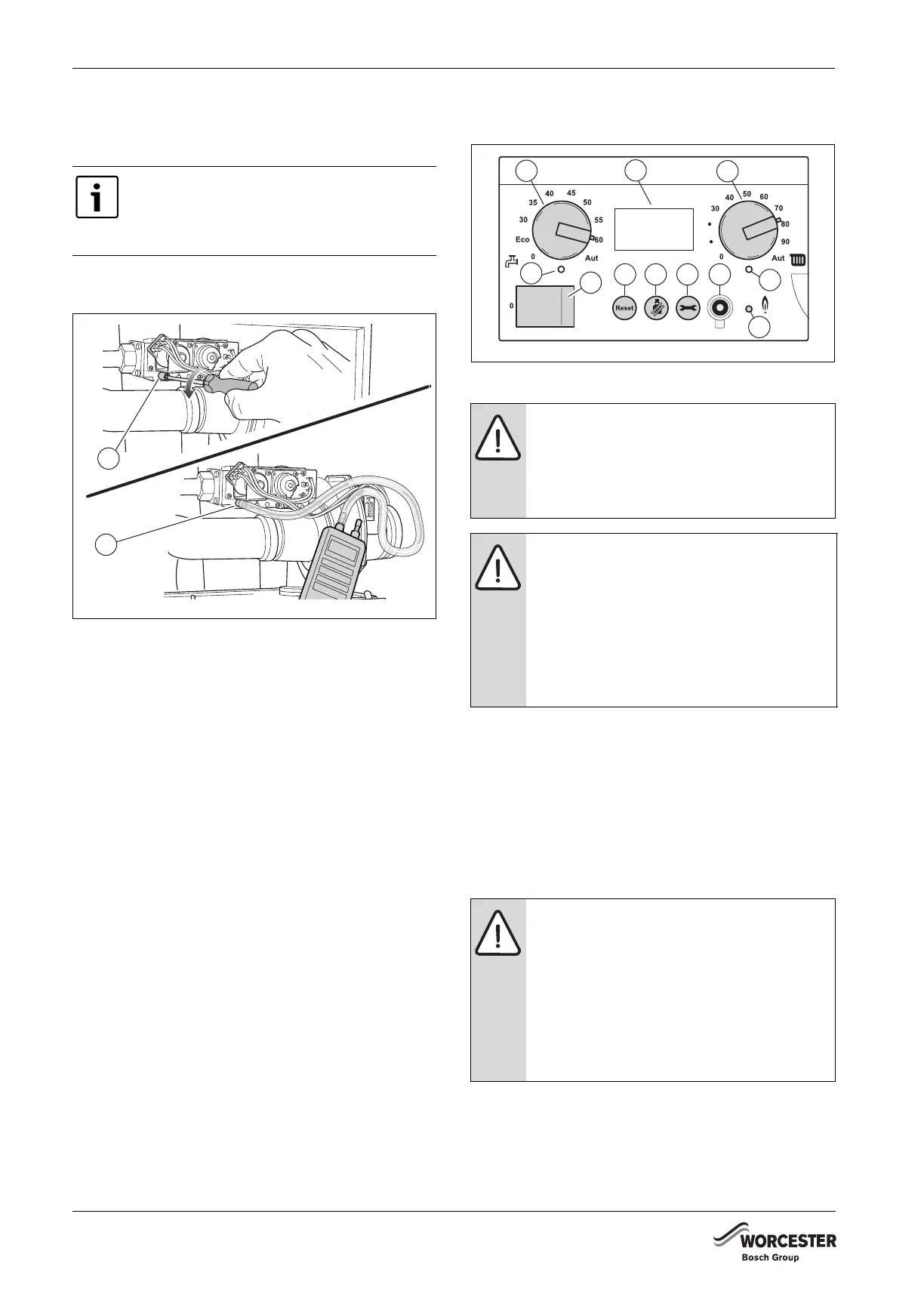

B Switch on the heating system by pressing the mains

switch [1] of the BC10 basic controller.

B Press and hold the "Chimney sweep" button [3]

(approx. 2 seconds), until the dot in the right-hand

bottom corner of the display [9] appears. See also

table 10, "Flue gas test", page 42.

B After the "Burner" LED [6] has lit up wait for one

minute until the boiler is burning at full load.

B Measure the gas supply pressure and enter it in the

commissioning log book, page 72.

The gas supply pressure must be:

• for natural gas H min. 17 mbar, max. 25 mbar, nominal

supply pressure 20 mbar.

• for LPG min. 30 mbar, max. 50 mbar, nominal supply

pressure 37 mbar.

B Press the "Service" button [4] repeatedly until the

temperature reading is shown in the display.

B Press the "Chimney sweep" button [3] to clear the

reading. Also see table 10, "Flue gas test", page 50.

Fig. 86 BC10 basic controller

B Close the gas valve (Æ fig. 81, page 50).

B Remove the gauge-connection tube and tighten the

screw plug on the testing nipple again.

B Open the gas valve again by pushing on the gas valve

and turning it ¼ rotation in an anticlockwise direction

(Æ fig. 79, page 49).

10.2.7 CHECKING AND ADJUSTING THE GAS/AIR-

RATIO

B Open at least 2 thermostatic radiator valves. Do not

switch on the boiler.

B Push on the control panel to open it (Æ fig. 68,

page 40).

Throughout the measuring operation, keep

the digital pressure gauge in the same

position (horizontal or vertical) in which it

was reset to "0".

6 720 648 726-085.1TD

2

1

DANGER: Danger of fatal accident from

explosive fumes.

B Check the testing nipples used for leaks.

B Only use approved leak detection spray

to locate leaks.

NOTE:

B Check the gas supply pipe or contact the

relevant gas utility company if the

required supply pressure is not available.

B If the supply pressure is too high, a gas

pressure regulator must be integrated

upstream of the gas fitting. Contact the

gas utility company.

WARNING:

Damage to the boiler by incorrect

adjustment of the gas/air-ratio.

B Adjust gas/air-ratio ONLY with part load!

B Adjust gas/air-ratio ONLY based on the

gas/air pressure differential and never

based on measured flue gas values such

as CO/CO

2

/NO

x

!

888

1

10

9

8

7

6

5432

1

6 720 648 726-069.1TD

11

Loading...

Loading...