Detailed Specifications Xerox

®

Versant® 80 Press

Customer Expectation and Installation Guide Xerox Confidential 7

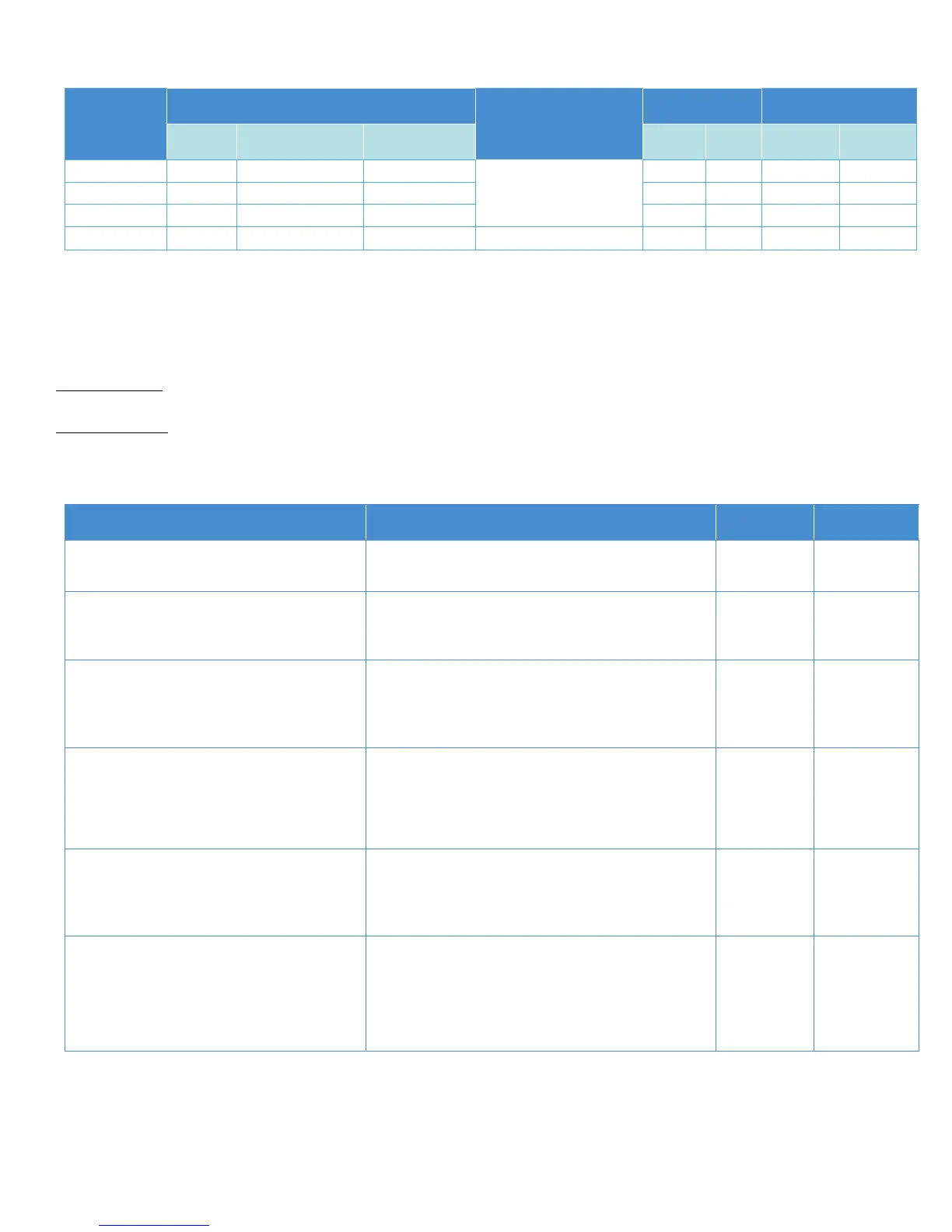

Media Size

Paper Feed Length

Media Type / Weight

Press Speed (ppm) Press Speed Feeding from

Bypass Tray 5 (ppm)

Feed

Direction*

Min Max

Simplex Duplex Simplex

Duplex

8.5x14 in / B4

SEF

11.71 in / 298.1 mm 14.3 in / 365 mm 25 13 25 13

11x17 in / A3

SEF

14.4 in / 366 mm 17 in / 432.0 mm 22 11 21 11

12x18 in / SRA3

SEF

17.1 in / 431.9 mm 19 in / 482.6 mm 20 10 19 10

8.5x11 in / A4

LEF

7.2 in / 182.0 mm 8.5 in / 216.0 mm

Tab Paper (106 - 176 gsm)

64 32 53 27

* LEF = Long edge feed; SEF = Short edge feed

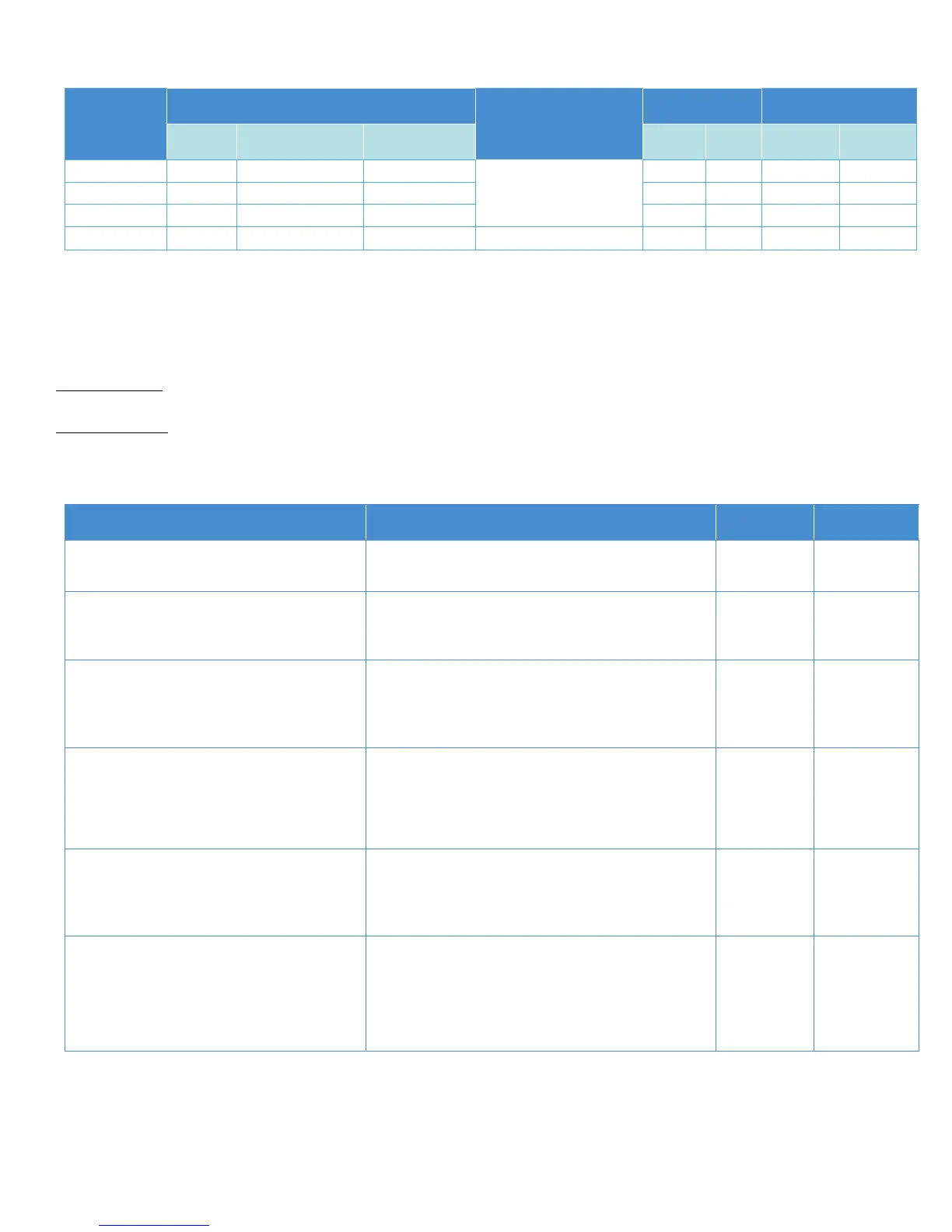

Tray Switching and Mixed Media Test Results

Press Productivity Modes

The Xerox New 80 Press allows the user to select from 2 Productivity Modes that impact the print speed of mixed media jobs. Descriptions of these modes and

test results are cited below. Note – test results refer to Versant 80 speeds without the Performance Package. Performance Package test results will be released in

a future edition of this document.

Optimized for Speed: (Default mode) This mode uses the maximum temperature for the heaviest stock within the job and won’t stop to adjust the fuser

temperature.

Optimized for Quality: This mode adjusts the fuser temperature for each stock weight range and the system productivity will slow down to allow the press to

adjust the fuser temperature when necessary.

The following table provides test results on several job types that utilize mixed media and that require paper tray switching. These jobs were tested by Xerox to

provide representative productivity. Results for similar jobs may vary depending on the Print Server, specific media, paper trays, and print mode that are used.

Job Description Configuration or Settings Optimized for

Speed

Optimized for

Quality

10 sheets:

All 8.5 x 11 in LEF 90 gsm

Alternating between two trays; 1 sheet per tray

Run to HCS and Standard Finisher Stacker Tray with set offset

Auto Tray Switch Timing set to Tray Near Empty

80

80

10 sheets:

All 8.5 x 11 in LEF

Sheets 1 and 10, 210 gsm

Sheets 2-9, 90 gsm

Run to Standard Finisher Stacker Tray with set offset

Auto Tray Switching defined in the job

1-Sided

80

13

3 sheets from different trays:

All 8.5 x 11 in LEF

Sheet 1: 200gsm (Tray 1)

Sheet 2: 90gsm (Tray 2)

Sheet 3: 90gsm (Tray 3)

Run to Standard Finisher Stacker Tray with set offset

Auto Tray Switching defined in the job

1-Sided

80

4

30 sheets:

All 11 x 17 in

90 gsm uncoated

Sheets 1-10: Tray 1

Sheets 11-20: Tray 2

Sheets 21-30: Tra

y 3

Run to Standard Finisher Stacker Tray with set offset

Auto Tray Switching defined in the job

1-Sided

44

44

23 sheets:

All 8.5 x 11 in LEF

90gsm

4 from tray 1, 1 from tray 3, repeat 3 times

Then 1 from tray 1, 1 from tray 3, repeat 4 times

Run to Standard Finisher Stacker Tray with set offset

Auto Tray Switching defined in the job

1-Sided

80

80

225 pages:

8.

5 x 11 in

210gsm cover

90 gsm body with 13

9 x 11 in tabs

15 sheets between tabs: Cover, 15 sheets, Tab, 15

sheets, Tab, 15 sheets, Tab, 15 sheets, Cover

Run to Standard Finisher Stacker Tray with set offset

Auto Tray Switching defined in the job

75

75

Loading...

Loading...