No. Item Page(s)

5 The voltage from the power supply should be within the input voltage specification range of the drive. –

6 The voltage rating for the motor should match the drive output specifications.

12

7 Verify that the drive is properly sized to run the motor.

Main Circuit Wiring

8 Confirm proper branch circuit protection as specified by national and local codes. 17

9

Properly wire the power supply to drive terminals R/L1, S/L2, T/L3, R1/L11, S1/L21, and T1/L31.

Note: Confirm that a 6-Phase/12-Pulse isolation transformer with each of the output windings phase-shifted

by 30 electrical degrees or a Hybrid 6-Phase topology is installed on the power supply.

20

10

Properly wire the drive and motor together.

The motor lines and drive output terminals U/T1, V/T2, and W/T3 should match in order to produce the desired phase

order. If the phase order is incorrect, the drive will rotate in the opposite direction.

–

11 Use 600 Vac vinyl-sheathed wire for the power supply and motor lines. 25

12

Use the correct wire gauges for the main circuit.

• Consider the amount of voltage drop when selecting wire gauges. Increase the wire gauge when the voltage drop is

greater than 2% of motor rated voltage. Ensure the wire gauge is suitable for the terminal block. Use the following

formula to calculate the amount of voltage drop:

Line drop voltage (V) = 3 × wire resistance (Ω/km) × wire length (m) × current (A) × 10

-3

• If the cable between the drive and motor exceeds 50 m, adjust the carrier frequency set to C6-02 accordingly.

25

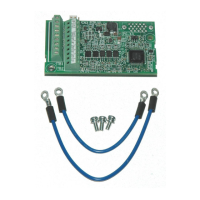

13 Properly ground the drive. –

14 Tighten control circuit and grounding terminal screws. 25

15

Set up overload protection circuits when running multiple motors from a single drive.

M1

OL1

OL2

OLn

MC1

MC2

MCn

M2

Mn

Drive

MC1 - MCn

OL 1 - OLn

... magnetic contactor

... thermal relay

Power supply

Note: Close MC1 – MCn before operating the drive. MC1 – MCn cannot be switched off during run.

–

16

Install a magnetic contactor when using a dynamic braking option. Properly install the resistor and ensure that overload

protection shuts off the power supply using the magnetic contactor.

–

17 Verify phase advancing capacitors, input noise filters, or GFCIs are NOT installed on the output side of the drive. –

Control Circuit Wiring

18 Use twisted-pair line for all drive control circuit wiring. –

19

Ground the shields of shielded wiring to the GND terminal.

–

20 For 3-Wire sequence, set parameters for multi-function contact input terminals S1 – S8, and wire control circuits. –

21 Properly wire any option cards. –

22 Check for any other wiring mistakes. Only use a multimeter to check wiring. –

23 Properly fasten drive control circuit terminal screws. 25

24 Pick up all wire clippings. –

25 Ensure that no frayed wires on the terminal block are touching other terminals or connections. –

26 Properly separate control circuit wiring and main circuit wiring. –

27 Analog signal line wiring should not exceed 50 m. –

28 Safe Disable input wiring should not exceed 30 m. –

3 Electrical Installation

YASKAWA TOEP YAIP1U 04A YASKAWA AC Drive – P1000 6-Phase/12-Pulse Input Installation Manual

27

Loading...

Loading...