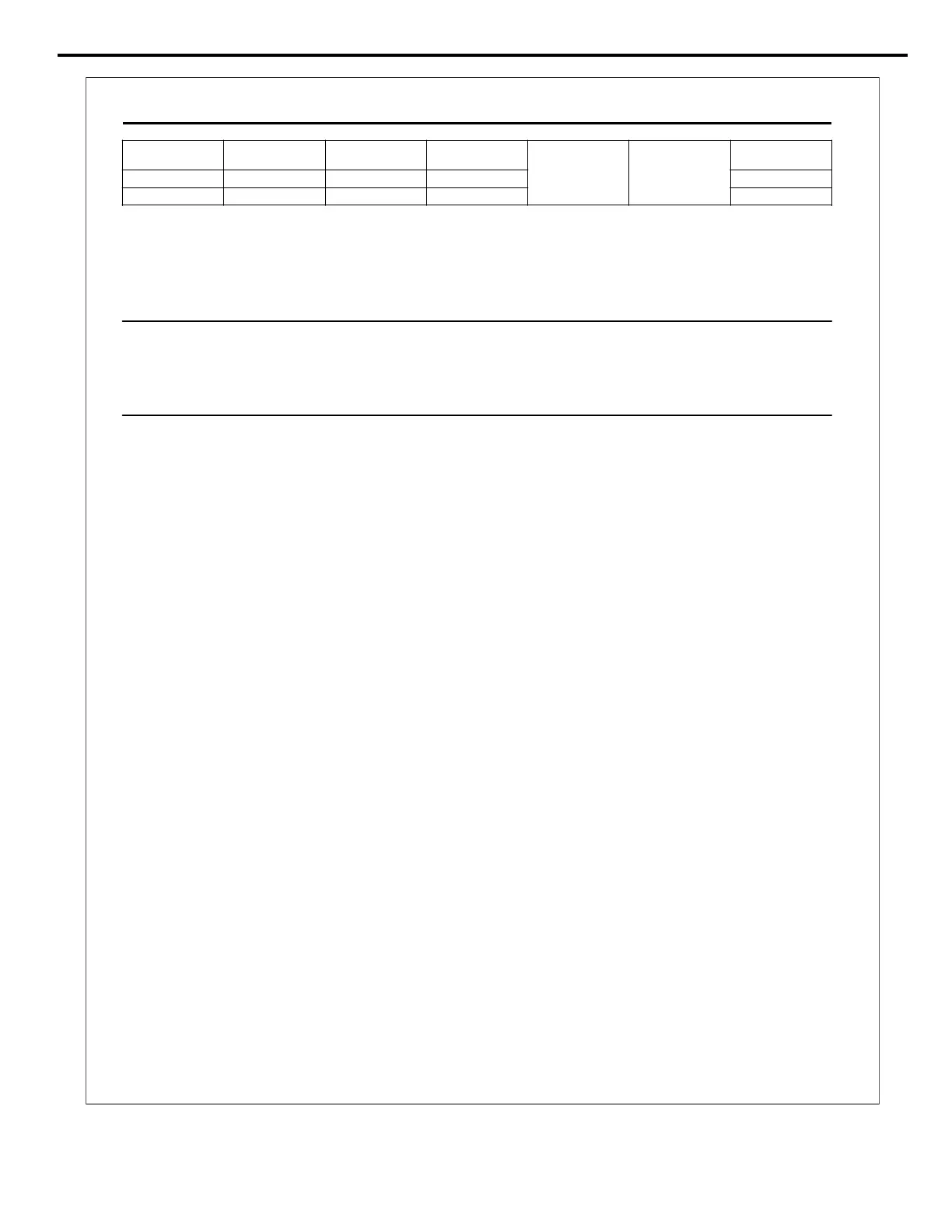

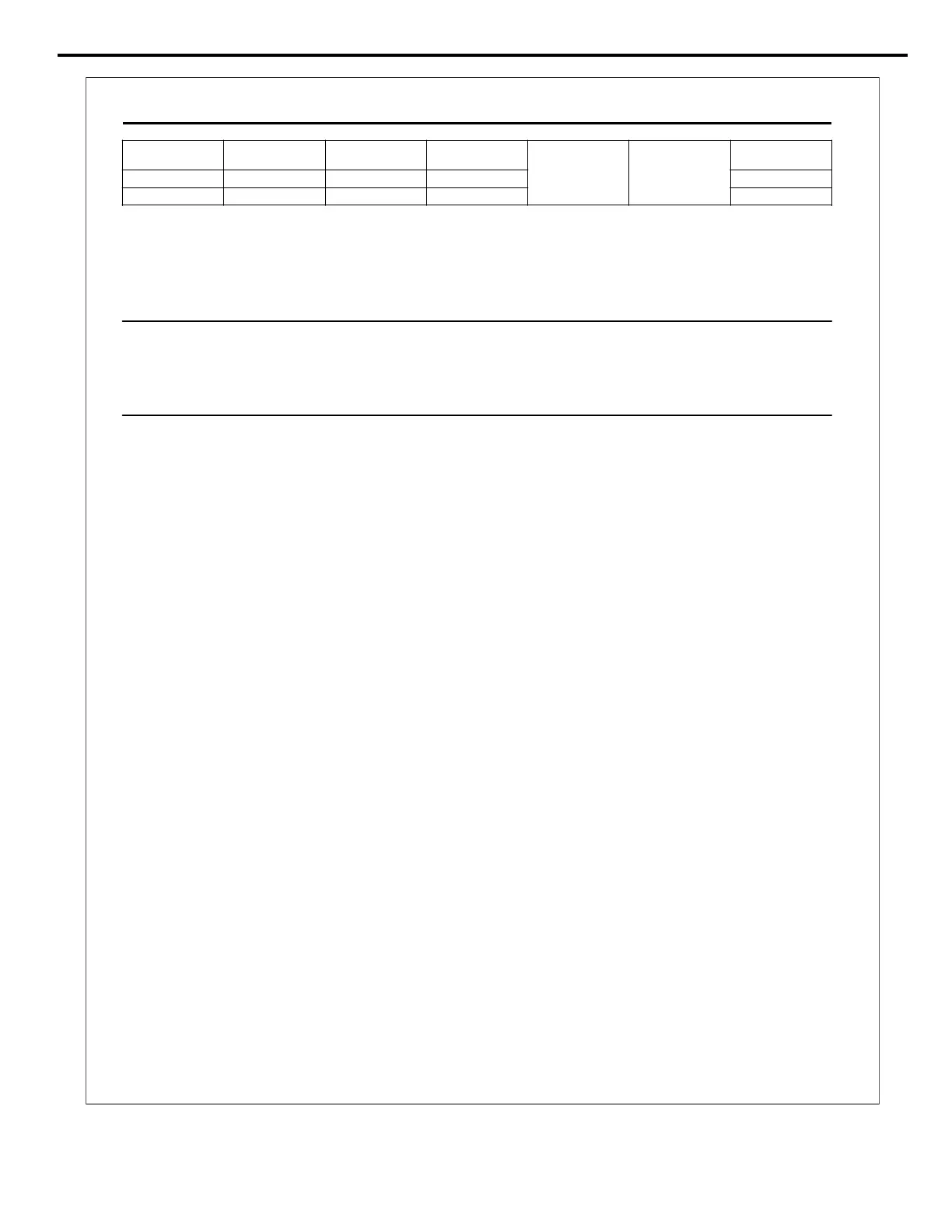

4A0480 400 480 900

<5> <5>

FWH-700A (700)

4A0515 450 515 1000 FWH-800A (800)

4A0590 500 590 1100 FWH-1000A (1000)

<1> Maximum MCCB rating is 15 A, or 200% of drive input current rating, whichever value is larger. MCCB voltage rating must be 600 Vac or greater.

<2> Maximum Time delay fuse is 175% or drive input current rating. This covers any Class J, T, or CC fuse.

<3> Maximum Non-time delay fuse is 300% of drive input current rating. This covers any Class J, T, or CC fuse.

<4> When using semiconductor fuses, Bussmann FWH fuses are required for UL compliance.

<5> Consult factory.

<6> Class L fuse is also approved for this rating.

uu

Attachment for External Heatsink Mounting

An external attachment can be used to project the heatsink outside of an enclosure to ensure that there is sufficient air circulation

around the heatsink.

Contact a Yaskawa sales representative or Yaskawa directly for more information on this attachment.

uu

Installing a Motor Thermal Overload (oL) Relay on the Drive Output

Motor thermal overload relays protect the motor by disconnecting power lines to the motor due to a motor overload condition.

Install a motor thermal overload relay between the drive and motor:

• When operating multiple motors on a single AC drive.

• When using a power line bypass to operate the motor directly from the power line.

It is not necessary to install a motor thermal overload relay when operating a single motor from a single AC drive. The AC

drive has UL recognized electronic motor overload protection built into the drive software.

Note: 1. Disable the motor protection function (L1-01 = 0) when using an external motor thermal overload relay.

2. The relay should shut off main power on the input side of the main circuit when triggered.

nn

General Precautions when Using Thermal Overload Relays

Consider the following application precautions when using motor thermal overload relays on the output of AC drives to prevent

nuisance trips or overheat of the motor at low speeds:

1. Low speed motor operation

2. Use of multiple motors on a single AC drive

3. Motor cable length

4. Nuisance tripping resulting from high AC drive carrier frequency.

Low Speed Operation and Motor Thermal oL Relays

Generally, thermal relays are applied on general-purpose motors. When general-purpose motors are driven by AC drives, the

motor current is approximately 5% to 10% greater than if driven by a commercial power supply. In addition, the cooling

capacity of a motor with a shaft-driven fan decreases when operating at low speeds. Even if the load current is within the motor

rated value, motor overheating may occur. A thermal relay cannot effectively protect the motor due to the reduction of cooling

at low speeds. For this reason, apply the UL recognized electronic thermal overload protection function built into the drive

whenever possible.

UL Recognized Electronic Thermal Overload Function of the Drive

Speed-dependent heat characteristics are simulated using data from standard motors and force-ventilated motors. The motor

is protected from overload using this function.

Using a Single Drive to Operate Multiple Motors

Set parameter L1-01 to 0 to disable thermal overload protection for the drive.

Note: The UL recognized electronic thermal overload function cannot be applied when operating multiple motors with a single drive.

Long Motor Cables

When a high carrier frequency and long motor cables are used, nuisance tripping of the thermal relay may occur due to increased

leakage current. To avoid this, reduce the carrier frequency or increase the tripping level of the thermal overload relay.

6.4 Installing Peripheral Devices

246

YASKAWA ELECTRIC TOEP C710616 45B YASKAWA AC Drive – Z1000 User Manual

Loading...

Loading...