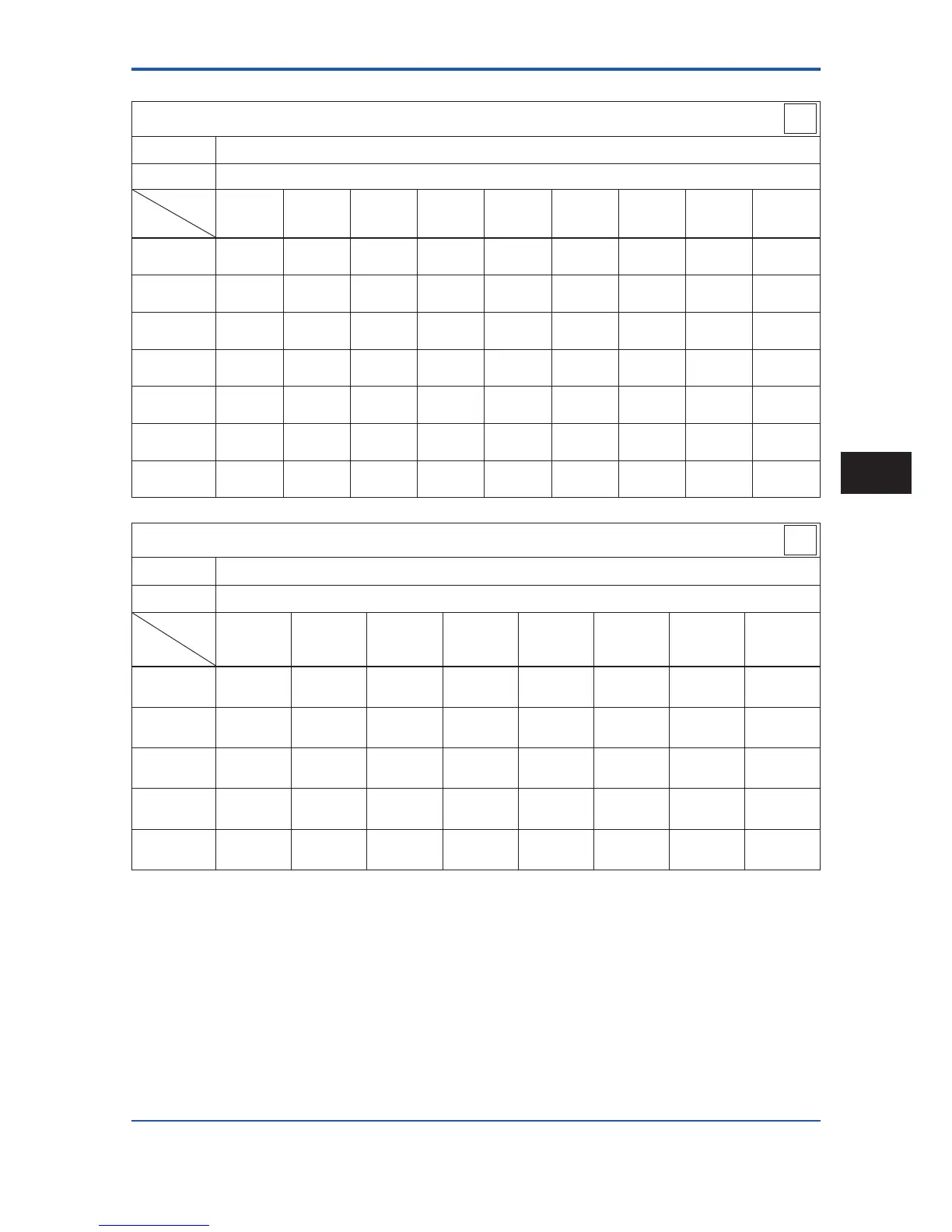

Table 3.3.8 Wafer Type Tightening Torque Values for PVC Piping

Tightening torque values for PFA lining type

Gasket types

withinowtube

Fluororubber gasket (optional codes GA, GC, and GD)

Gasket types

foruser’sange

Fluororubber gasket, chloroprene rubber gasket (optional codes BSC and BCC), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI

Class 150

DIN PN10 JIS 20K

ANSI

Class 300

DIN PN16 DIN PN40

JIS F12

(JIS 75M)

JPI

Class 150

50 (2.0)

9.9 to 16.5

{101.0 to 168.3}

[87.6 to 146.0]

9.9 to 16.5

{101.0 to 168.3}

[87.6 to 146.0]

—

10.6 to 17.6

{108.1 to 179.5}

[93.8 to 155.8]

10.6 to 17.6

{108.1 to 179.5}

[93.8 to 155.8]

—

9.5 to 15.9

{96.9 to 162.1}

[84.1 to 140.7]

―

9.6 to 15.9

{98.1 to 162.2}

[85.1 to 140.7]

65 (2.5)

14.2 to 23.7

{144.8 to 241.7}

[125.7 to 209.8]

14.2 to 23.7

{144.8 to 241.7}

[125.7 to 209.8]

—

15.5 to 25.9

{158.1 to 264.1}

[137.2 to 229.2]

15.5 to 25.9

{158.1 to 264.1}

[137.2 to 229.2]

28.2 to 51.8

{287.6 to 528.2}

[249.6 to 458.4]

— — —

80 (3.0)

8.0 to 13.3

{81.6 to 135.6}

[70.8 to 117.7]

17.4 to 26.7

{177.4 to 272.3}

[154.0 to 236.3]

—

9.7 to 16.1

{98.9 to 164.2}

[85.8 to 142.5]

9.7 to 16.1

{98.9 to 164.2}

[85.8 to 142.5]

9.7 to 16.1

{98.9 to 164.2}

[85.8 to 142.5]

—

15.4 to 25.6

{157.0 to 261.0}

[136.3 to 226.6]

16.4 to 27.0

{167.1 to 275.9}

[145.0 to 239.3]

100 (4.0)

11.3 to 18.8

{115.2 to 191.7}

[100.0 to 166.4]

11.3 to 18.8

{115.2 to 191.7}

[100.0 to 166.4]

—

14.2 to 23.6

{144.8 to 240.7}

[125.7 to 208.9]

14.2 to 23.6

{144.8 to 240.7}

[125.7 to 208.9]

14.2 to 23.6

{144.8 to 240.7}

[125.7 to 208.9]

—

21.1 to 35.1

{215.2 to 357.9}

[186.7 to 310.6]

10.6 to 17.5

{108.2 to 178.3}

[93.8 to 154.7]

125 (5.0)

18.8 to 31.3

{191.7 to 319.2}

[166.4 to 277.0]

18.8 to 31.3

{191.7 to 319.2}

[166.4 to 277.0]

—

22.3 to 37.2

{227.4 to 379.3}

[197.4 to 329.2]

22.3 to 37.2

{227.4 to 379.3}

[197.4 to 329.2]

22.3 to 37.2

{227.4 to 379.3}

[197.4 to 329.2]

—

18.5 to 30.8

{188.6 to 314.1}

[163.7 to 272.6]

—

150 (6.0)

22.5 to 37.6

{229.4 to 383.4}

[199.1 to 332.8]

22.5 to 37.6

{229.4 to 383.4}

[199.1 to 332.8]

—

27.2 to 45.3

{277.4 to 461.9}

[240.7 to 400.9]

27.2 to 45.3

{277.4 to 461.9}

[240.7 to 400.9]

40.7 to 62.1

{415.0 to 633.2}

[360.2 to 549.6]

—

21.8 to 36.3

{222.3 to 370.2}

[192.9 to 321.3]

19.9 to 32.0

{202.8 to 326.0}

[175.9 to 282.8]

200 (8.0)

22.1 to 36.9

{225.4 to 376.3}

[195.6 to 326.6]

31.9 to 55.3

{325.3 to 563.9}

[282.3 to 489.4]

31.9 to 55.3

{325.3 to 563.9}

[282.3 to 489.4]

27.3 to 45.3

{278.4 to 461.9}

[241.6 to 400.9]

27.3 to 45.3

{278.4 to 461.9}

[241.6 to 400.9]

27.3 to 45.3

{278.4 to 461.9}

[241.6 to 400.9]

—

23.8 to 39.6

{242.7 to 403.8}

[210.6 to 350.5]

30.6 to 49.2

{312.3 to 501.7}

[270.9 to 435.2]

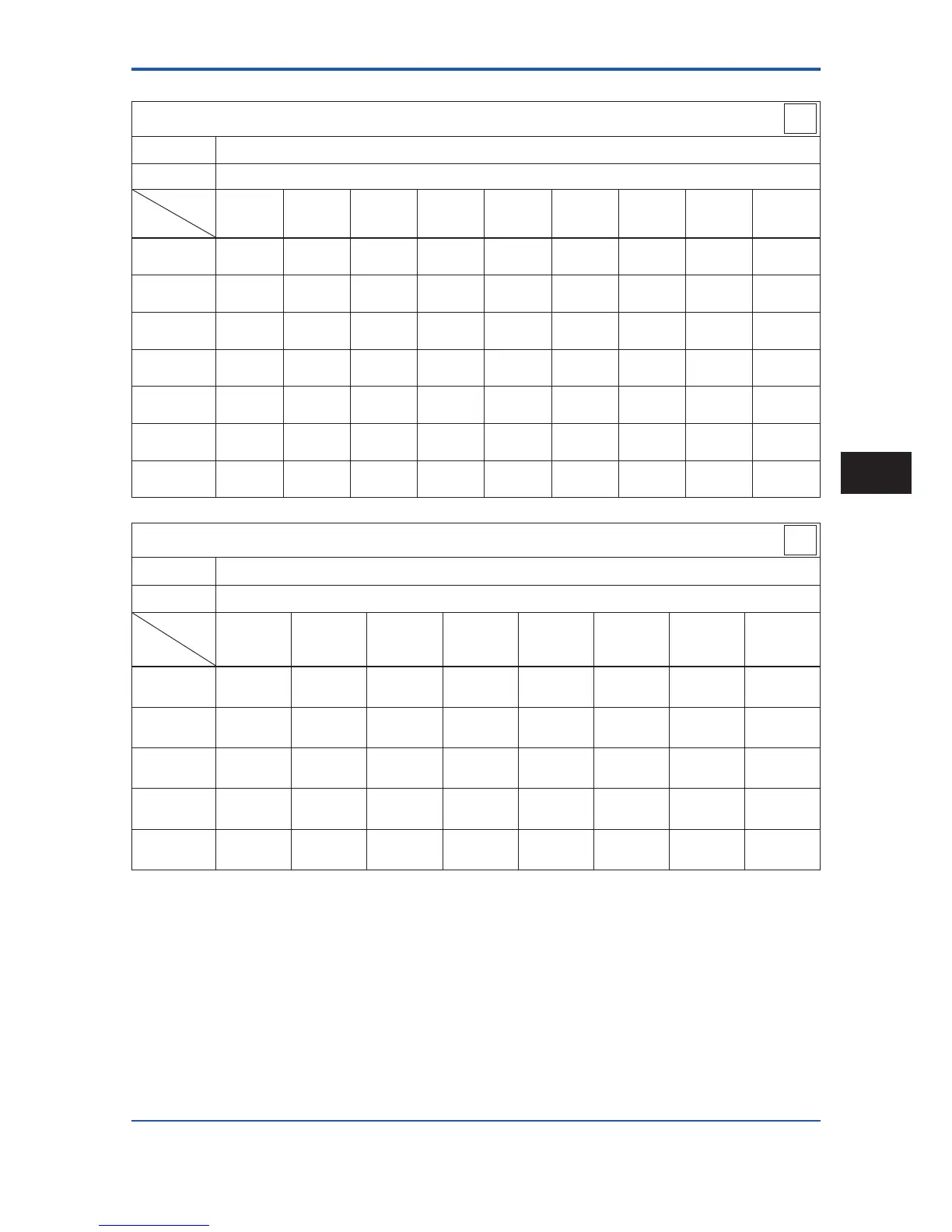

Tightening torque values for Ceramics lining type

Gasket types

withinowtube

Fluororubber gasket (optional codes GA, GC, and GD)

Gasket types

foruser’sange

Fluororubber gasket, chloroprene rubber gasket (optional codes BSC and BCC), or the equivalent in hardness

Flange

ratings

Size

mm (inch)

JIS 10K

ANSI

Class 150

DIN PN10 JIS 20K

ANSI

Class 300

DIN PN16 DIN PN40

JIS F12

(JIS 75M)

50 (2.0)

6.2 to 10.4

{63.2 to 106.1}

[54.9 to 92.0]

6.3 to 10.5

{64.2 to 107.1}

[55.8 to 92.9]

—

2.9 to 4.9

{29.6 to 50.0}

[25.7 to 43.4]

2.9 to 4.9

{29.6 to 50.0}

[25.7 to 43.4]

―

6.2 to 10.4

{63.2 to 106.1}

[54.9 to 92.0]

―

80 (3.0)

4.4 to 7.3

{44.9 to 74.4}

[38.9 to 64.6]

10.6 to 17.7

{108.1 to 180.5}

[93.8 to 156.7]

―

5.3 to 8.8

{54.0 to 89.7}

[46.9 to 77.9]

5.2 to 8.7

{53.0 to 88.7}

[46.0 to 77.0]

4.4 to 7.3

{44.9 to 74.4}

[38.9 to 64.6]

―

9.6 to 16.0

{97.9 to 163.2}

[85.0 to 141.6]

100 (4.0)

5.2 to 8.6

{53.0 to 87.7}

[46.0 to 76.1]

5.7 to 9.5

{58.1 to 96.9}

[50.4 to 84.1]

―

6.0 to 10.0

{61.2 to 102.0}

[53.1 to 88.5]

6.0 to 10.0

{61.2 to 102.0}

[53.1 to 88.5]

5.2 to 8.6

{53.0 to 87.7}

[46.0 to 76.1]

―

11.7 to 19.5

{119.3 to 198.8}

[103.6 to 172.6]

150 (6.0)

10.7 to 17.8

{109.1 to 181.5}

[94.7 to 157.5]

11.6 to 19.3

{118.3 to 196.8}

[102.7 to 170.8]

―

7.0 to 11.6

{71.4 to 118.3}

[62.0 to 102.7]

6.6 to 11.0

{67.3 to 112.2}

[58.4 to 97.4]

10.7 to 17.8

{109.1 to 181.5}

[94.7 to 157.5]

―

13.3 to 22.2

{135.6 to 226.4}

[117.7 to 196.5]

200 (8.0)

10.2 to 17.1

{104.0 to 174.4}

[90.3 to 151.3]

18.9 to 31.5

{192.7 to 321.2}

[167.3 to 278.8]

18.7 to 31.2

{190.7 to 318.2}

[165.5 to 276.1]

10.6 to 17.7

{108.1 to 180.5}

[93.8 to 156.7]

10.8 to 18.0

{110.1 to 183.5}

[95.6 to 159.3]

10.2 to 17.1

{104.0 to 174.4}

[90.3 to 151.3]

―

15.3 to 25.5

{156.0 to 260.0}

[135.4 to 225.7]

Unit:

N-m

{kgf-cm}

[in-lbf]

Unit:

N-m

{kgf-cm}

[in-lbf]

Loading...

Loading...