6. Operation

Afteryouhaveinstalledtheowtubeintotheprocess

piping, wired the input/output terminals, set up the

required parameters, and performed a pre-operation zero

adjustment,themagneticowmetershouldoutputan

accurateowsignalfromitsterminalsassoonasowof

theuidtobemeasuredbegins.Thissectiondescribes

zero adjustment and the corresponding procedures.

6.1 Pre-operation Zero

Adjustment

Zero adjustment is carried out to ensure that the output

forzeroowis0%(i.e.,4mA).Althoughadjustmentto

zero is performed at the manufacturing plant prior to

shipment, this procedure must be carried out once again

following the installation of piping in order to match the

magneticowmetertoitsoperatingconditions.

This section describes the zero adjustment procedure

using display unit switches from the converter. Also, it

can be operated using the BT200 Handheld Terminal.

Accordingly, one of these methods should be selected

and implemented.

IMPORTANT

• Zero adjustment should be carried out before

actual operation. Note that setting and update

functions cannot be carried out during this

procedure (i.e., for approximately 30 seconds).

• Zero adjustment should only be carried out when

theowtubehasbeenlledwithmeasurement

uidandtheuidvelocityiscompletelyzeroby

closing the valve.

• Eachtimethattheuidbeingmeasuredis

changed, it will be necessary for zero adjustment

tobecarriedoutforthenewuid.

6.2 Zero Adjustment Using

Display Unit Switches

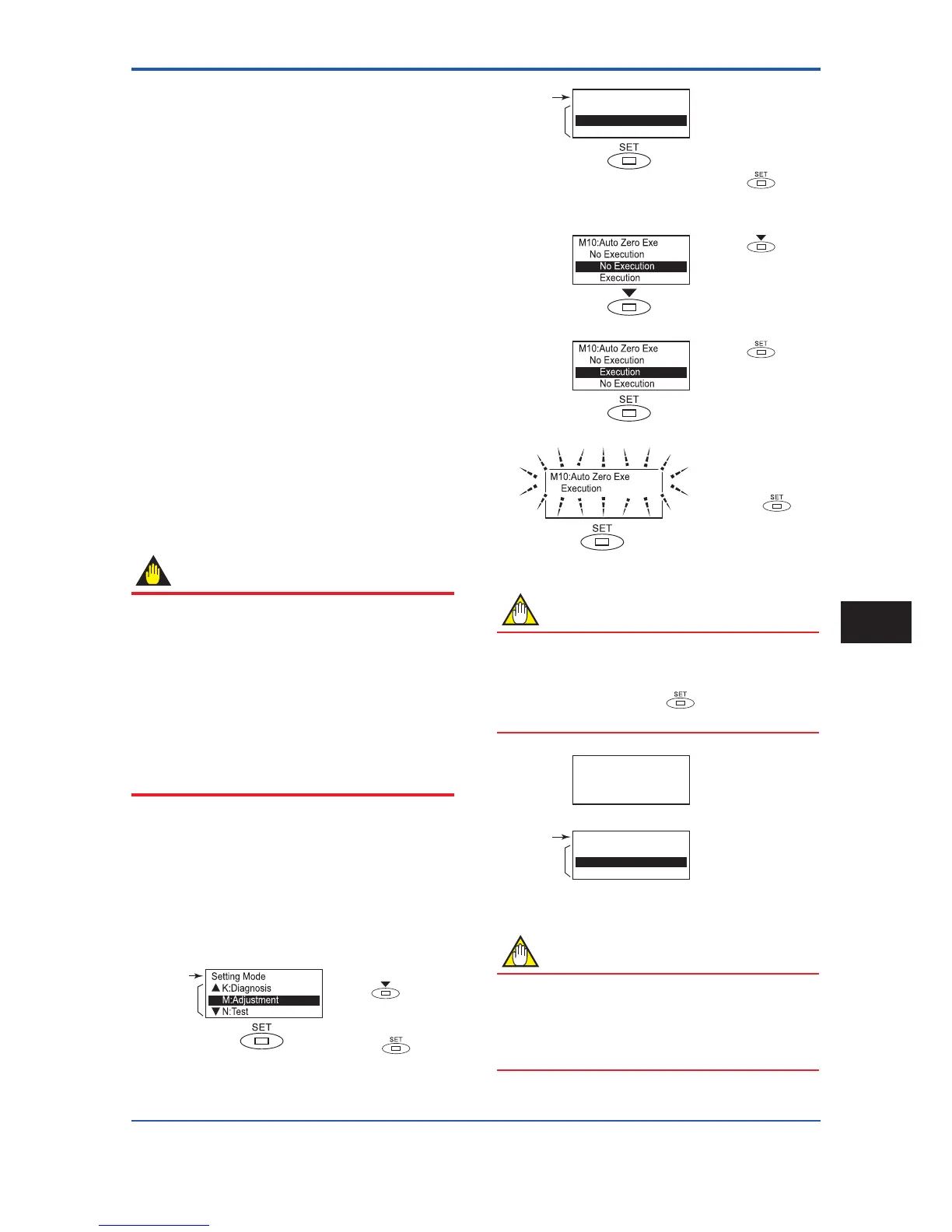

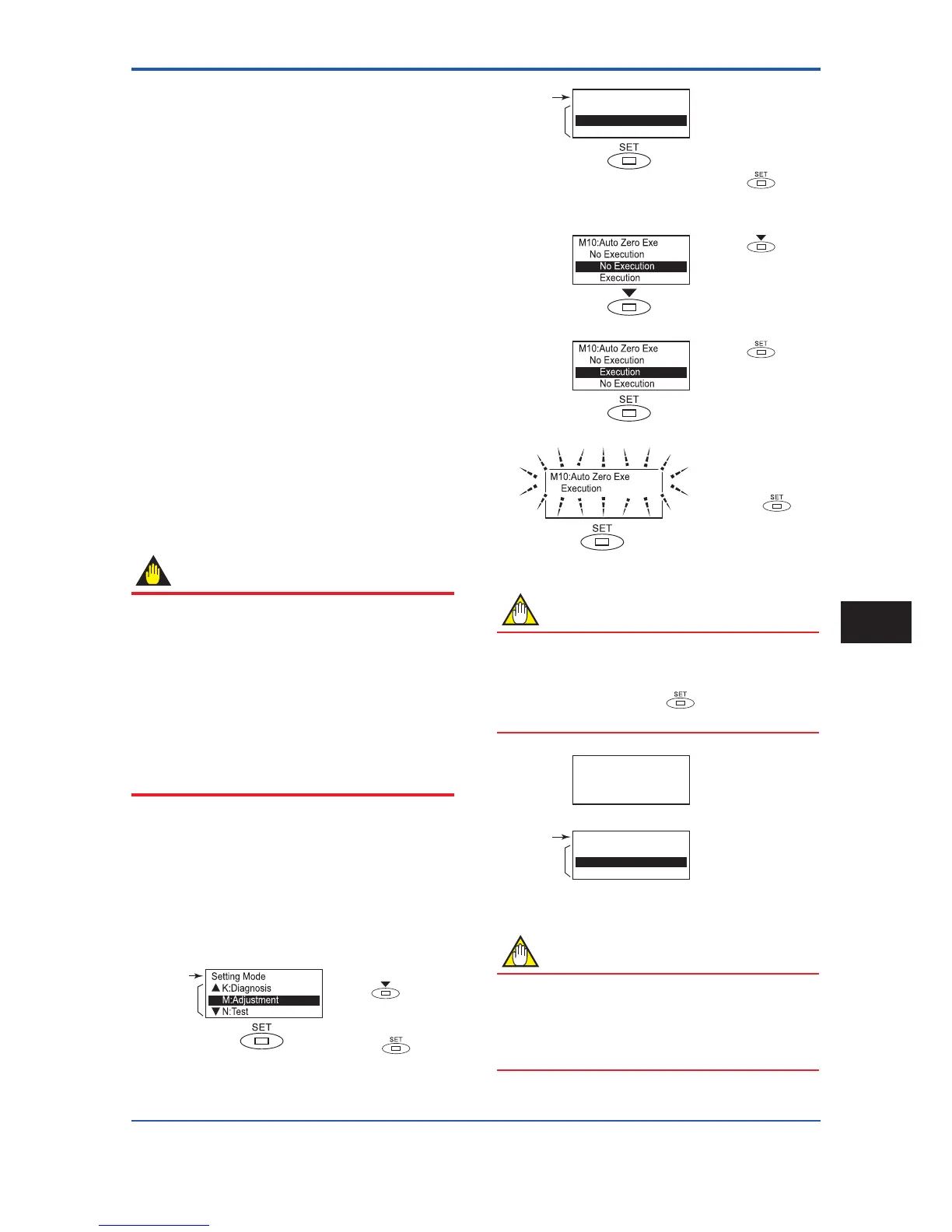

The parameters for zero adjustment are B50/M10: Auto

Zero Exe (and either of these can be used to carry out

this procedure). The parameter M10: Auto Zero Exe will

be used in the following description.

In order to request

conrmation,theentire

displayashesonand

off. Touch the

switch once again at

thistimetoxselection

of the automatic zero

adjustment function.

NOTE

When no operations are carried out for 20 seconds in

theashingstate,thesystemwillautomaticallyreturn

to the Sub-item Parameter Search Mode.

When the operations except

switch are carried

out, the parameter cannot be set.

Loading...

Loading...