<5. Maintenance>

5-1

IM 02M04B01-01EN

5. Maintenance

5.1 Basic Troubleshooting

DIFFICULTY:Noreading(orverylowreading)at

output gauge.

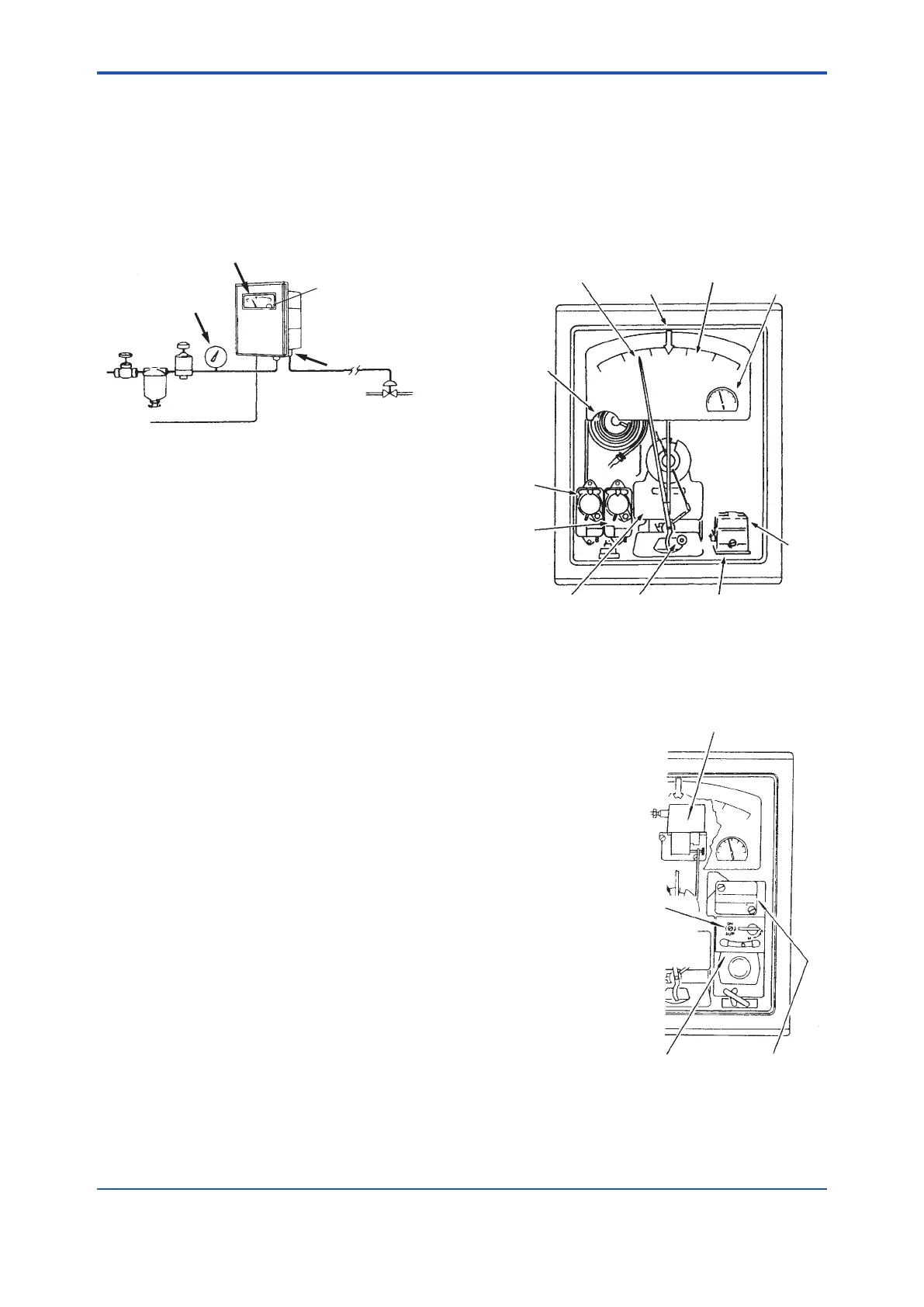

F0501.ai

1

2

Output gauge

4

1. Check that 140 kPa (1.4 kgf/cm

2

) is supplied to

controller.

2. Check for measurement reading.

3. Clean restrictor. (refer to section 5.3).

4. Disconnect output line and plug controller

output with nger.

5. Adjust set point knob (or remote set point, if

present) so that set point index goes above and

below measurement pointer. If output gauge

indicates normal control action, there is a leak

in output line or control valve.

6. If output gauge still indicates no control action,

a. Check controller for damage or leaks.

b. Replace amplier (refer to section 5.4).

c. Check control unit alignment (refer to section

5.11 and 5.12).

DIFFICULTY:Maximumpressureatalltimesat

output gauge.

1. Check for mechanical damage resulting in

nozzle always being covered by apper.

2. Check for misalignment of amplier gasket,

resulting in plugging.

3. Replace pneumatic amplier (refer to section

5.4).

4. Clean nozzle (refer to section 5.3).

5. Check control unit alignment (refer to section

5.11 and 5.12).

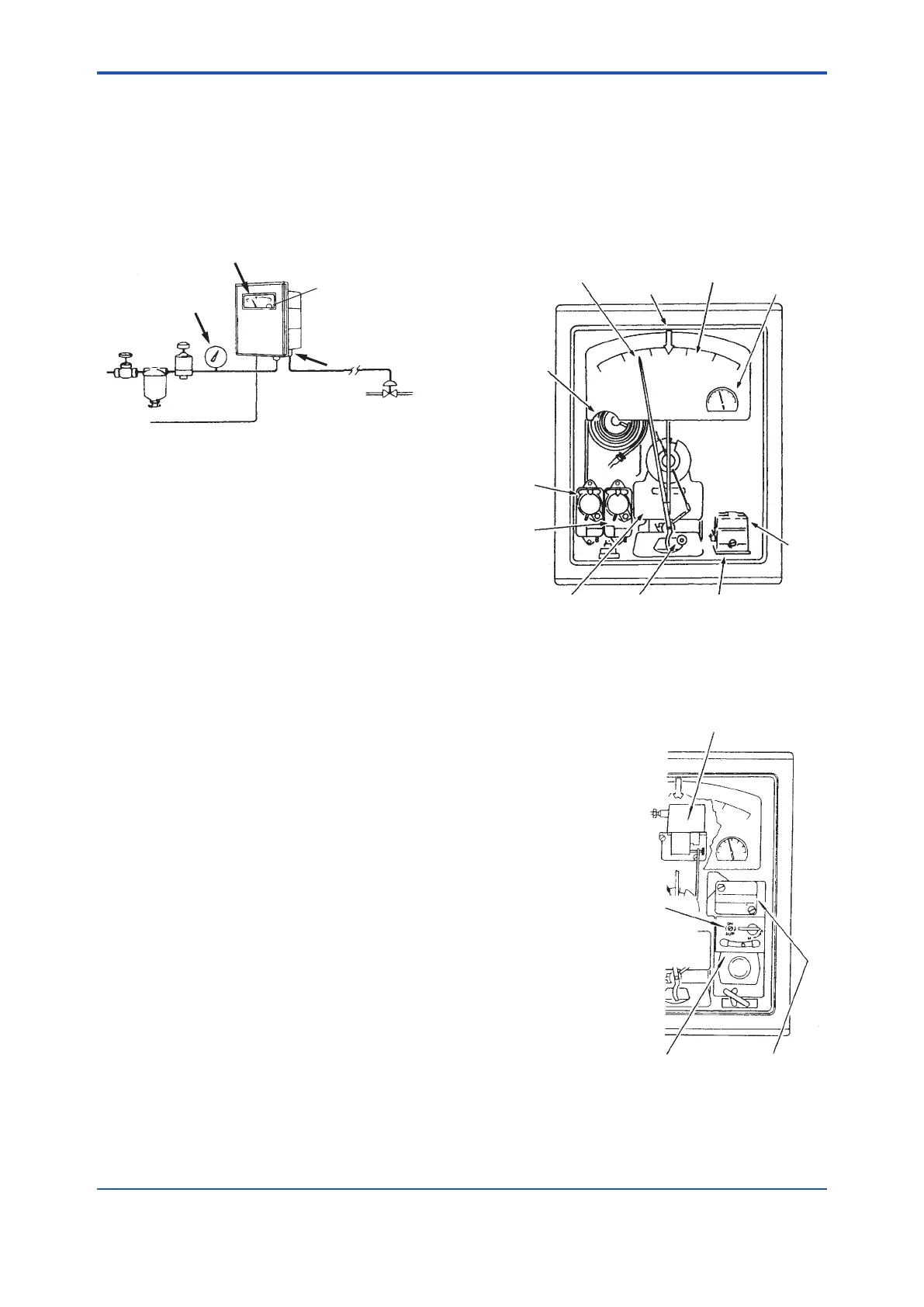

5.2 IdenticationofMajor

Components in Controller

(1) Model MC43-N-N

F0502.ai

Measurement

pointer

Set point index

Set point and

measurement dial

Output gauge

Measurement

element

(pressure type

illustrated)

Reset

assembly

(optional)

Derivative

assembly

(optional)

Control unit Set point knob Controller without

automatic-manual

transfer system

Pneumatic

amplifier

(2) Model MC43-C-P

F0503.ai

Remote set point element

(optional)

Pneumatic amplifierAuto-man transfer system

(optional)

Shutoff for air to automatic

control section

(controller with automatic-manual

transfer system).

Loading...

Loading...