<2. General>

2-2

IM 02M04B01-01EN

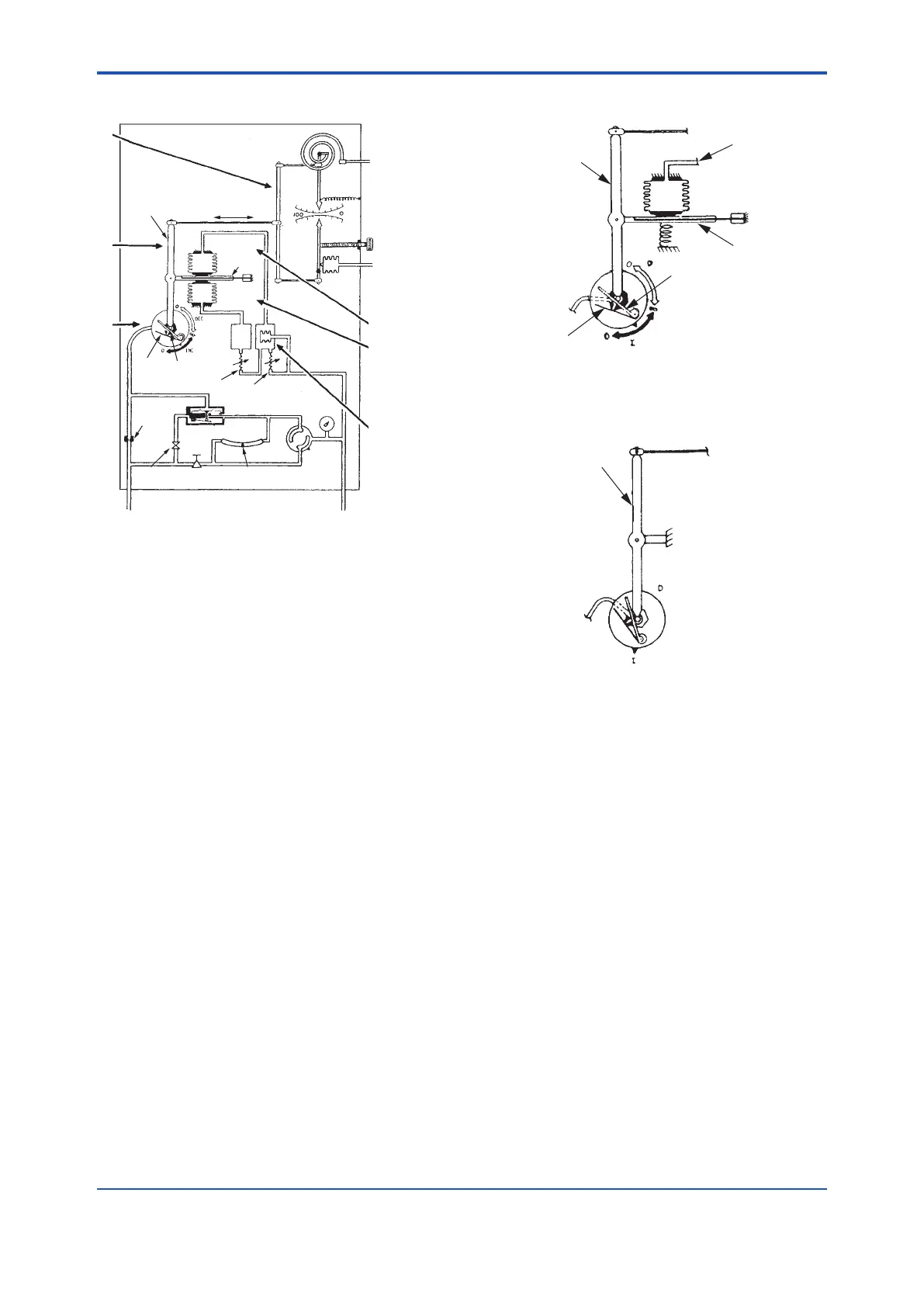

2.3 Principle of Operation

F0201.ai

1

2

3

4

5

6

Measurement

Local or remote

Proportioning

lever

Error

signal

Proportioning

bellows

Flat spring

Reset

bellows

Flapper

nozzle

Flapper

Striker bar

Reset restrictor

Derivative

restrictor

Reducing

tube

Amplifier

Shutoff

valve

Regulator Balance

indicator

Auto/Man

switch

Auto Man

Air supply

140 kPa (1.4kgf/cm

2

)

Output

Set point

Figure 2.1 Controller with Proportional, Reset,

andDerivativeActions,andAutomatic,

Manual Transfer System.

1. A differential linkage measures difference

between measurement pointer and setting

index positions. This error signal moves

proportioning lever.

2. Proportioning lever pivots at its center on end of

a at spring.

3. This motion changes apper nozzle

relationship, causing amplier to establish an

output pressure.

4. Output pressure is fed back to proportioning

bellows, which acts through proportioning lever

to rebalance apper-nozzle.

5. Reset bellows and tank assembly are used

when measuement must be maintained exactly

at control point (without “offset”).

6. Derivative tank assembly is used to improve

system response to a slow process.

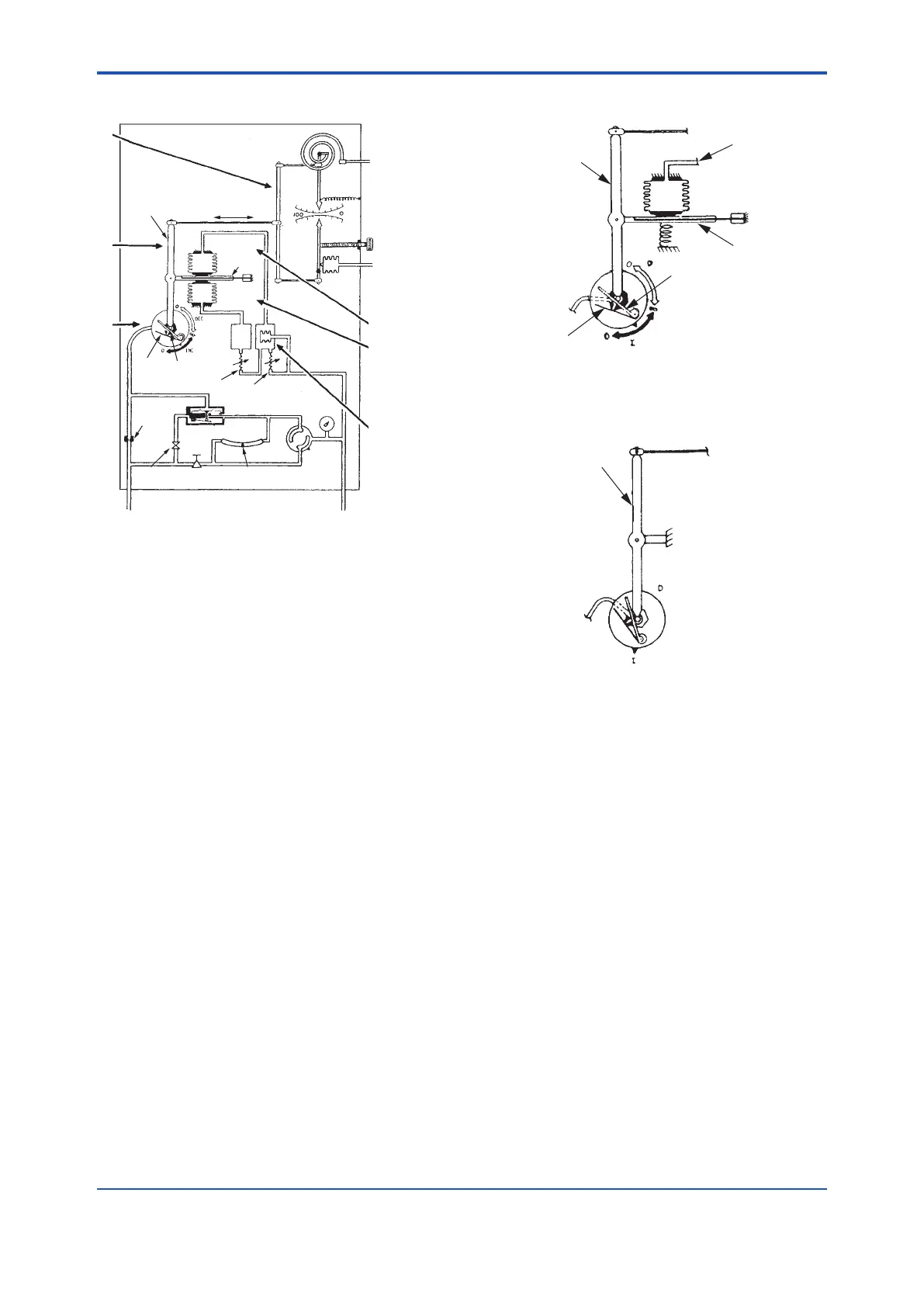

(1) Proportional Control

F0202.ai

Proportioning lever

Feedback from

relay output

Proportioning bellows

Flat spring

Striker bar

Flapper

For description, see Steps 1 through 4.

(2) On-Off Control

F0203.ai

Proportioning lever

Flapper nozzle

On-Off control is obtained by pivoting the

proportional lever about a xed point without

proportioning or reset bellows. This controller can

be equipped with an automatic shutdown unit.

Loading...

Loading...