<Appendix1.PressureElements>

A1-2

IM 02M04B01-01EN

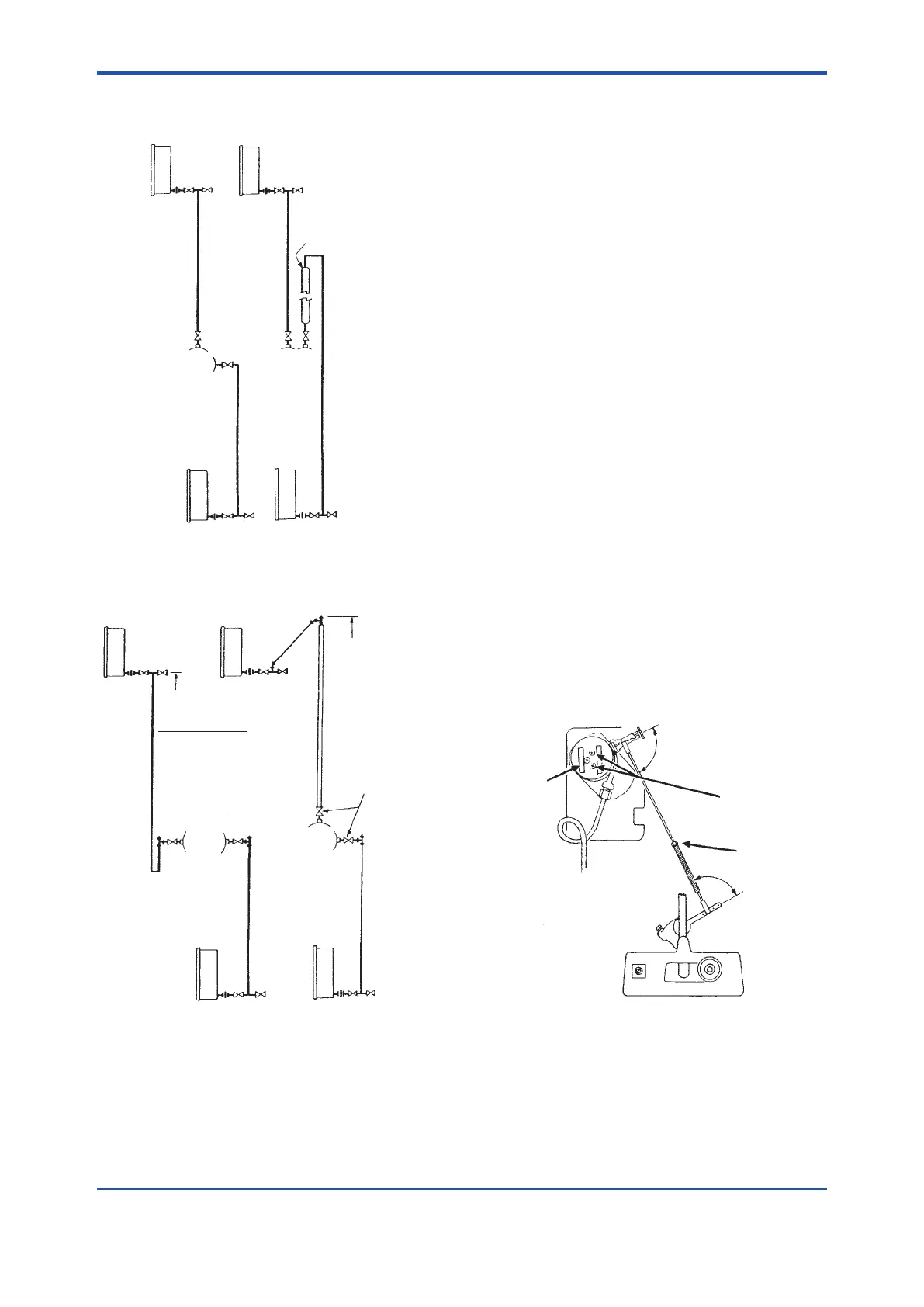

(4) PipingArrangements

FA0103.ai

A

A

AA

C C

C C

Dry Gas Wet Gas

Instrument

above line

Dry

gas

Wet Gas

Line or vessel under

measurement

Instrument

below line

Condensing pipe

(1.2 m of 2" pipe)

Gas-Filled Systems

FA0104.ai

1/2" insulated pipe

Keep as near vertical

as possible.

Liquid Steam

C

C

C

C

B B B

B

A A

A

A

Max height above line =

7.6

specific gravity

(m)

Pipe above

instrument

Gate valve

SteamLiquid

Liquid-FilledSystems

To Zero (Gas application)

Close valve A and open valve C. Use Zero

adjustment to bring the pointer to zero. Close valve

C and open valve A.

Valve C can be used for initial drainage in wet gas

applications with instrument below line.

To Fill Line (before zeroing)

Liquid:

Open valve A. Open valve C until liquid ows

free of bubbles. Close valve C.

Steam:

Open valve A and allow piping between plug B

and instrument to ll with condensate.

ToZero(Liquidandsteamapplication)

After lines are lled with liquid, close valve A and

remove plug B. Use Zero adjustment to bring the

pointer to zero. Replace plug B and open valve A.

A1.2 Calibrationand

Replacement of Pressure

Elements

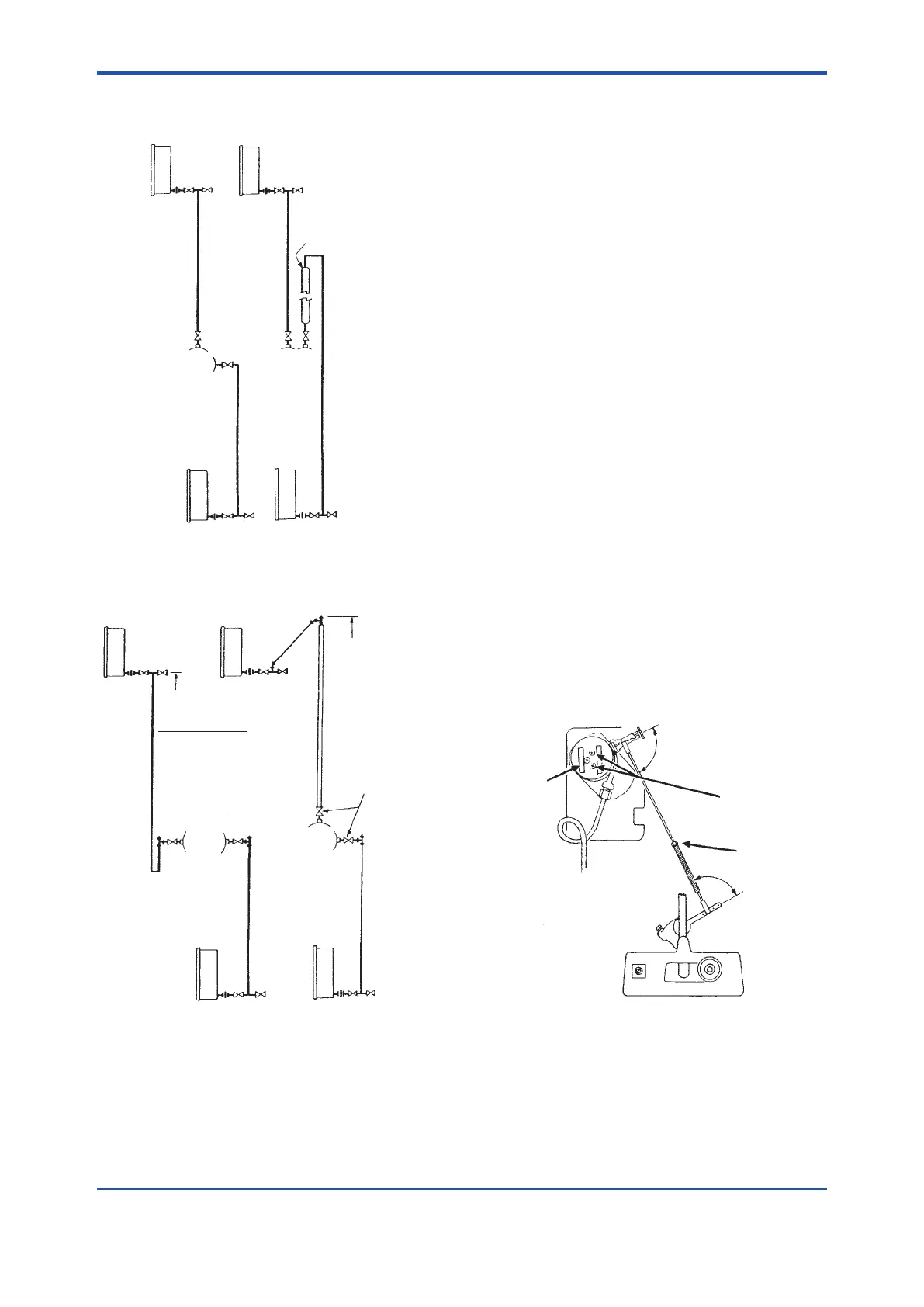

(1) SquaringUpofLinkageforComplete

Calibration

If parts have been replaced, or for some other

reason a complete recalibration is necessary,

square up the linkage before the actual calibration.

FA0105.ai

3

b

a

2

1

1. Set pressure at middle of element range (see

range on element nameplate).

2. Obtain right angle (a) by loosening the two

screws on top of element and slipping drive

lever on its shaft.

3. Obtain right angle (b) by adjusting length of link.

Loading...

Loading...