<Appendix2.ThermalElements>

A2-2

IM 02M04B01-01EN

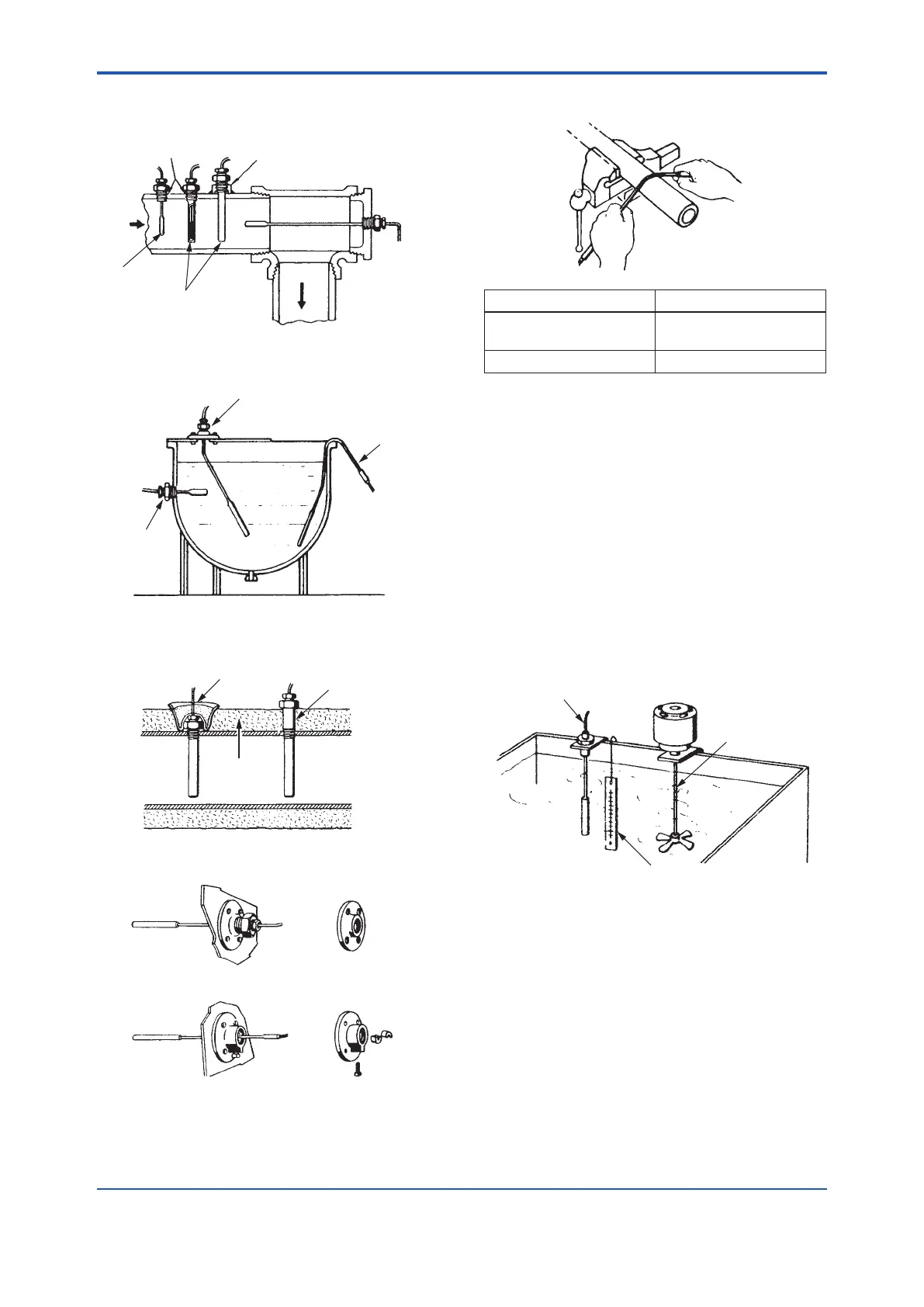

(5) Installing Temperature Bulb

FA0205.ai

In Pipe Line, Using Bushing or Well

Tapped hole in pipe

Half coupling welded to pipe

Well

Adjustable union

(AB type)

Fixed union

(FB type)

FA0206.ai

In Kettle or Retort

Adjustable union (AB type)

Only when strict sealing is

not required

Fixed union

(FB type)

Plain bulb

(NB type)

FA0207.ai

In Lagged (Insulated) Pipe Line

Lagging

Well with lagging

extension

Plug of insulation

held in cloth

FA0208.ai

In Duct or Wall

Clamp Flange - Split bushing clamps over

bulb extension or connecting tubing.

Threaded Flange - Supports bushing or well.

FA0209.ai

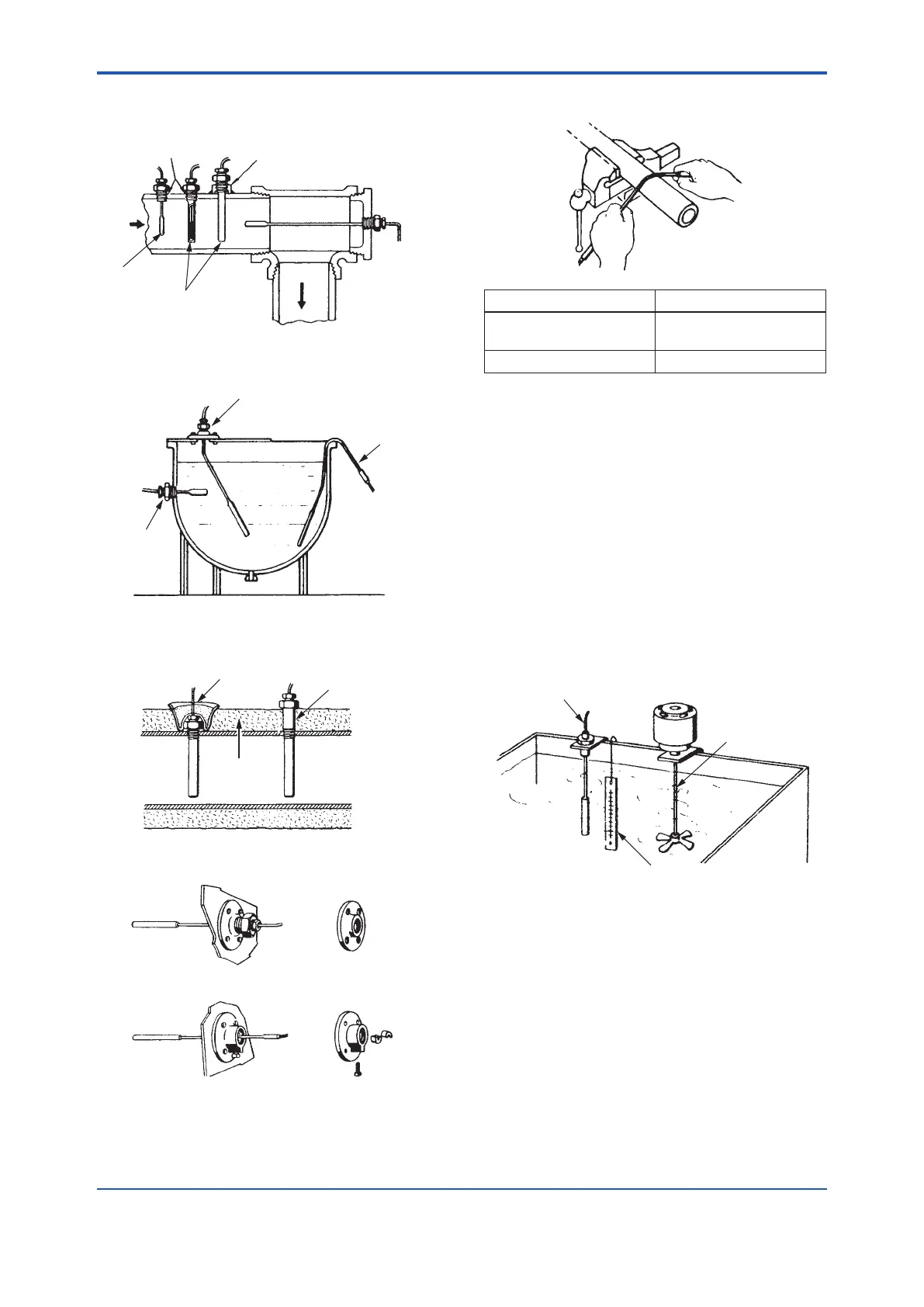

To Bend Tubing

Type of Tubing Minimum Bending Size

Plastic Coated

FlexibleTube

7.6 cm radius

Bulb Extension 3.0 cm radius

A2.2 Calibrationand

Replacement of Thermal

Elements

Two test baths at widely separated temperature in

the measurement range are required for thermal

element calibration. When ordering replacement

thermal element, specify the desired temperature

range. Yokogawa will supply a precalibrated

element. If you wish to check or calibrate an

element yourself, use the following procedure.

(1) CalibrationEquipment

To controller

Mechanical stirrer

Labolatory-grade

thermometer

FA0210.ai

1. Prepare two test baths at temperatures that are

widely separated on instrument scale.

2. Do not calibrate element in air or against

another element in process.

3. Remove element from process and place it

near a laboratory-grade thermometer in a well-

stired bath.

4. Allow sufcient time for element to reach liquid

temperature.

Loading...

Loading...