Page 18

TO GET ASSISTANCE, CALL: 919-774-7667

ZENITH PUMPS

1. Prepare the ZeDrive:

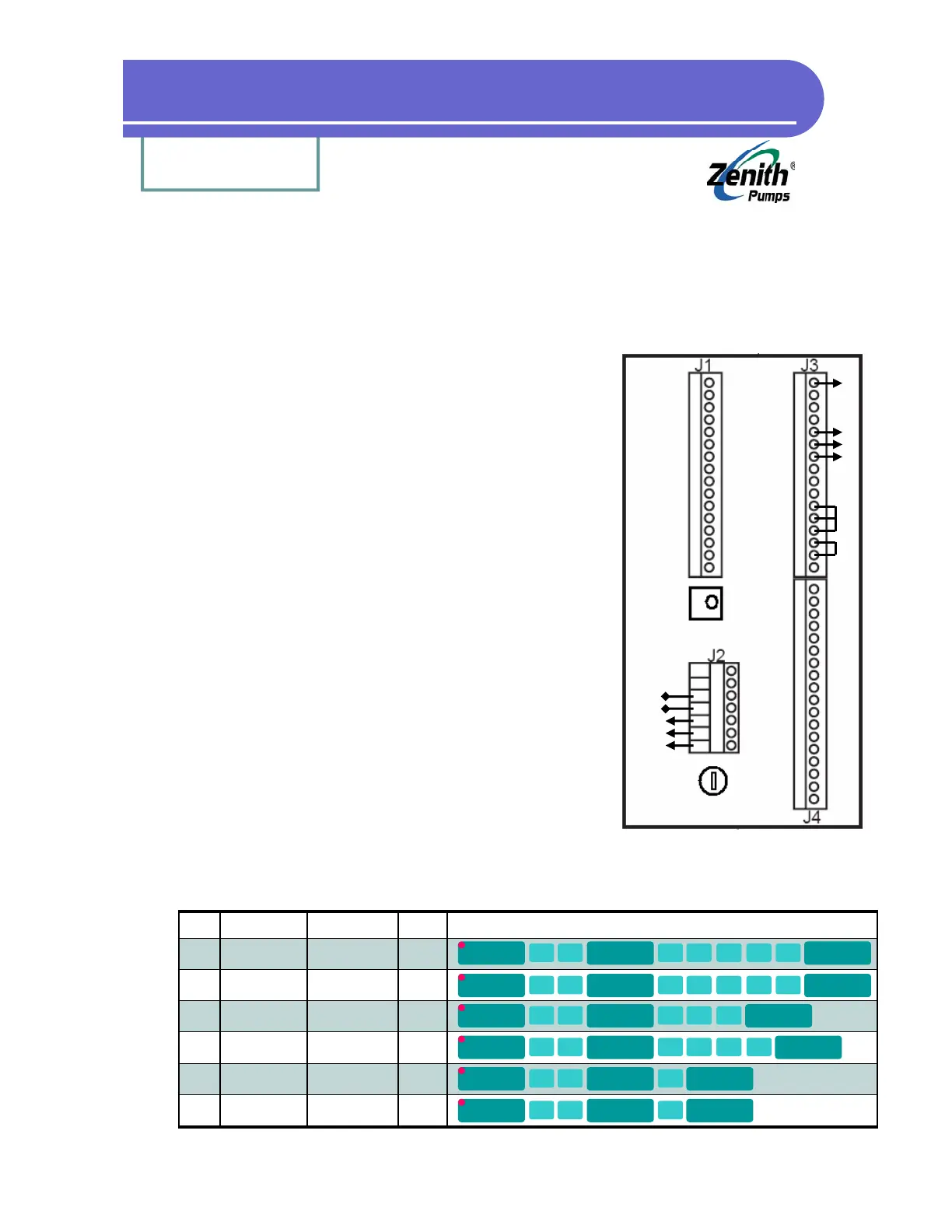

• Place jumpers on J3 connector between

Pin 11 - Pin 12

Pin 13 - Pin 12

Pin 14 - Pin 15

• Connect power wires to J2 connector Pin L1, Neutral and

Chassis GND (Do NOT turn on power at this time)

2. Prepare the Sensor:

• Screw the sensor into the thread hole located on the

gear reducer, until it hits the inside pickup gear, and

back up about 1/8 of a turn (45 degrees)

• If it is a 2-wire sensor, connect

White wire - J3 Pin 5

Black wire - J3 Pin 6

Bare wire - J3 Pin 7

• If it is a 3-wire sensor, connect

Red wire - J3 Pin 1

White wire - J3 Pin 5

Black wire - J3 Pin 6

Bare wire - J3 Pin 7

3. Connect Power to the Drive:

• Turn the 120 VAC power on for the ZeDrive

• If the power is 230 VAC, please refer to “Trouble-

shooting” section

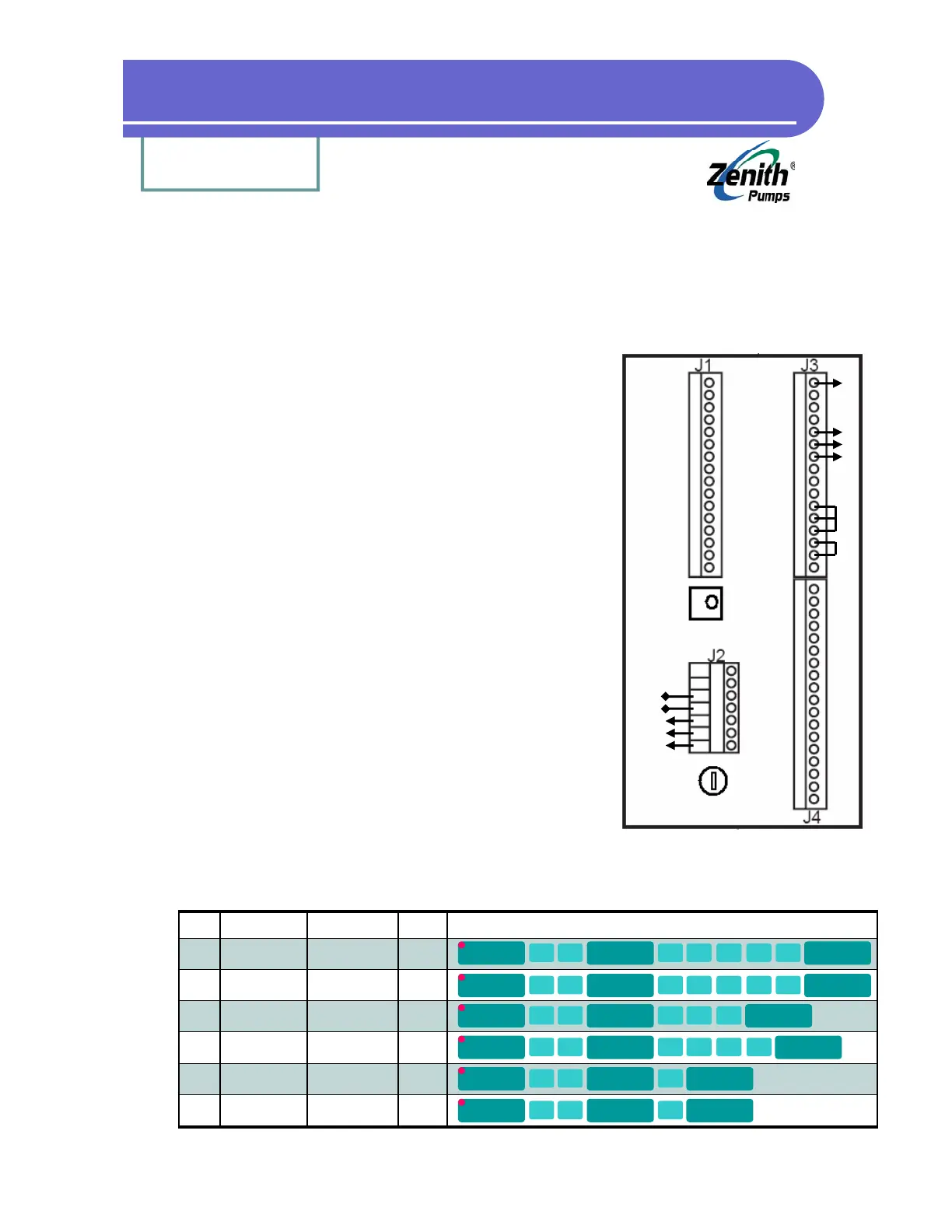

4. Configure ZeDrive:

A 5.091:1 reducer and 120 teeth pickup gear is used for the following example.

Change values for codes 20, 22 and 31 based on the system.

Quick Test for ZeDrive

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Red

Wht

Bare

Blk

To

Feedback

Sensor

Jumpers

To Motor

To AC

Power

A2

A1

L1

N

G

Back Panel of ZeDrive

Code Description Formula

20 Primary Setpoint

Eng. Unit

1800/Gear Ratio

(i.e., 5.091:1)

Default

353.6

Operation

22 Primary Display

Eng. Unit

1800/Gear Ratio

(i.e., 5.091:1)

353.6

31 No. of Teeth of

Feedback Gear

120 120

34 Primary RPM Max

Feedback

1800 1800

61 Primary Scaling

Format

1 1

63 Primary Display

Format

1 1

CODE

SELECT

2 0

ENTER

3 5 3

.

6

ENTER

CODE

SELECT

2 2

ENTER

3 5 3

.

6

ENTER

CODE

SELECT

3 1

ENTER

1 2 0

ENTER

CODE

SELECT

3 4

ENTER

1 8 0 0

ENTER

CODE

SELECT

6 1

ENTER

1

ENTER

CODE

SELECT

6 3

ENTER

1

ENTER

Loading...

Loading...