Page 31

TO GET ASSISTANCE, CALL: 919-774-7667

ZENITH PUMPS

Master/Follower System

1. Preliminary Action:

• Two individual ZeDrive systems are needed for forming

a master/follower system

• The following is only one example. For more detailed

system integration and configuration, please refer to

Chapter 5 in “ZeDrive and ZeTrol Manual”

• Master Reducer Gear Ratio — R

m

. If the pump is directly

coupled with the motor, the gear ratio R

m

=1

• Follower Reducer Gear Ratio — R

f

. If the pump is di-

rectly coupled with the motor, the gear ratio R

f

=1

• Motor maximum speed — V

M

(RPM), usually, 1800

(RPM)

• Master Pump Capacity — C

m

(cc/rev)

• Follower Pump Capacity — C

f

(cc/rev)

• Master Feedback Sensor Resolution — F

m

(No. of Teeth)

• Follower Feedback Sensor Resolution — F

f

(No. of Teeth)

2. Calculation:

2.1 Master Primary Setpoint — P

m

(cc/min)

P

m

(cc/min) = V

M

(RPM) / R

m

× C

m

(cc/rev)

2.2 Maximum Percent between Follower and Master — P

f

(%)

P

f

(%) = Follower Max. Flowrate (cc/min) / Master Max. Flowrate (cc/min)

= [ V

M

(RPM) / R

f

× C

f

(cc/rev) ] / [ V

M

(RPM) / R

m

× C

m

(cc/rev) ]

= [ R

m

/ R

f

] × [ C

f

/ C

m

]

3. Coding:

Check and change the following codes

For Master For Follower

Primary Setpoint, Eng. Unit Code 20 = P

m

Code 20 = P

f

Primary Display, Eng. Unit Code 22 = P

m

Code 22 = P

f

External Ref. Resolution, PPR Code 30 = F

m

Feedback Resolution, PPR Code 31 = F

m

Code 31 = F

f

Primary Max. External Ref. Speed, RPM Code 33 = V

M

Primary Max. Feedback Speed, RPM Code 34 = V

M

Code 34 = V

M

Primary Scaling Format Code 61 = 1 (Master) Code 61 = 2 (Follower)

Primary Display Format Code 63 = 1 (Master) Code 63 = 2 (Follower)

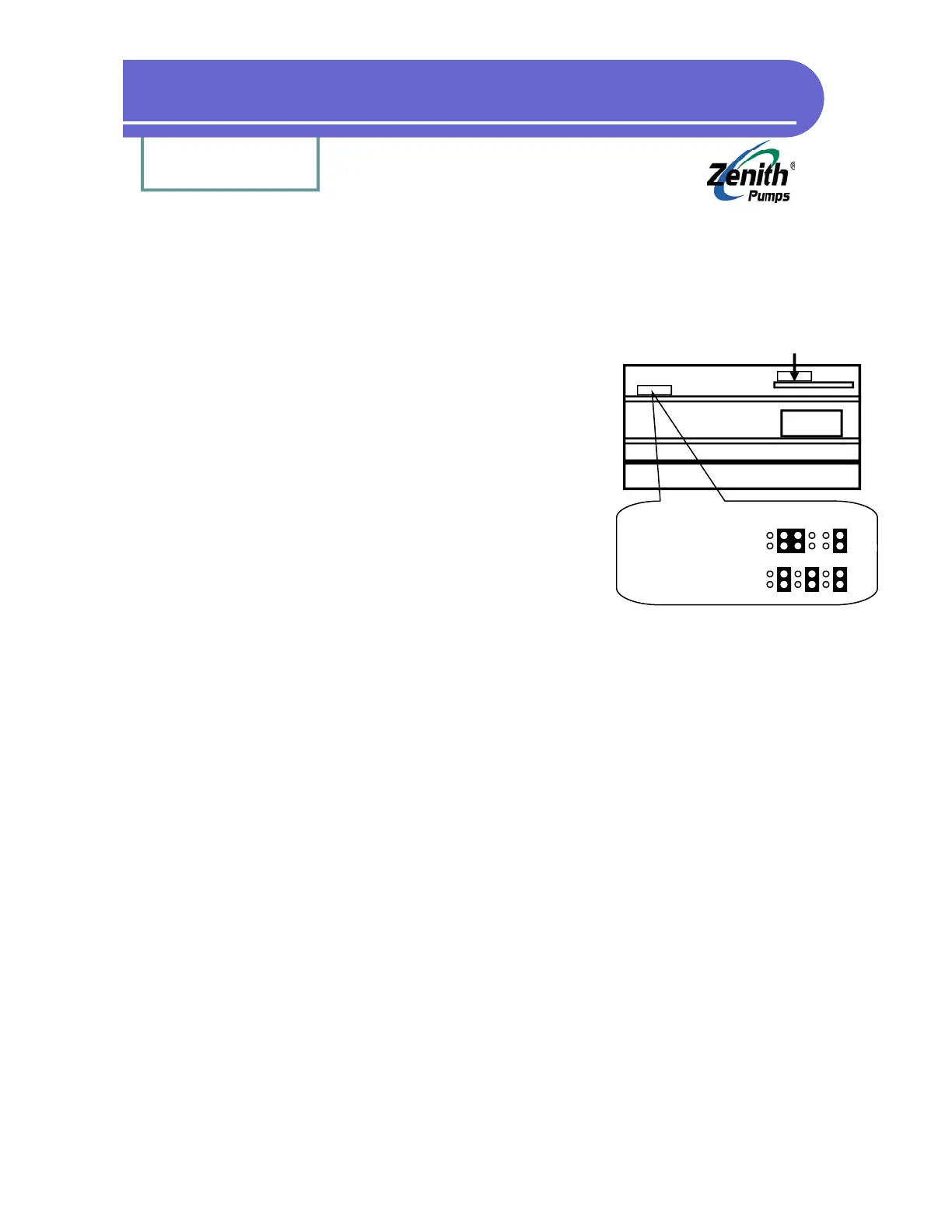

Analog I/O Board

(Not this jumper)

Heat Sink

Transformer

Jumper 1

(Feedback)

Feedback Jumper Location

3-wire Sensor (default):

Left

2-wire Sensor:

Left

Loading...

Loading...