36

RSMZ Technical Guide

APPENDIX A: TROUBLESHOOTING

Liquid Line and Head Pressure Transducer

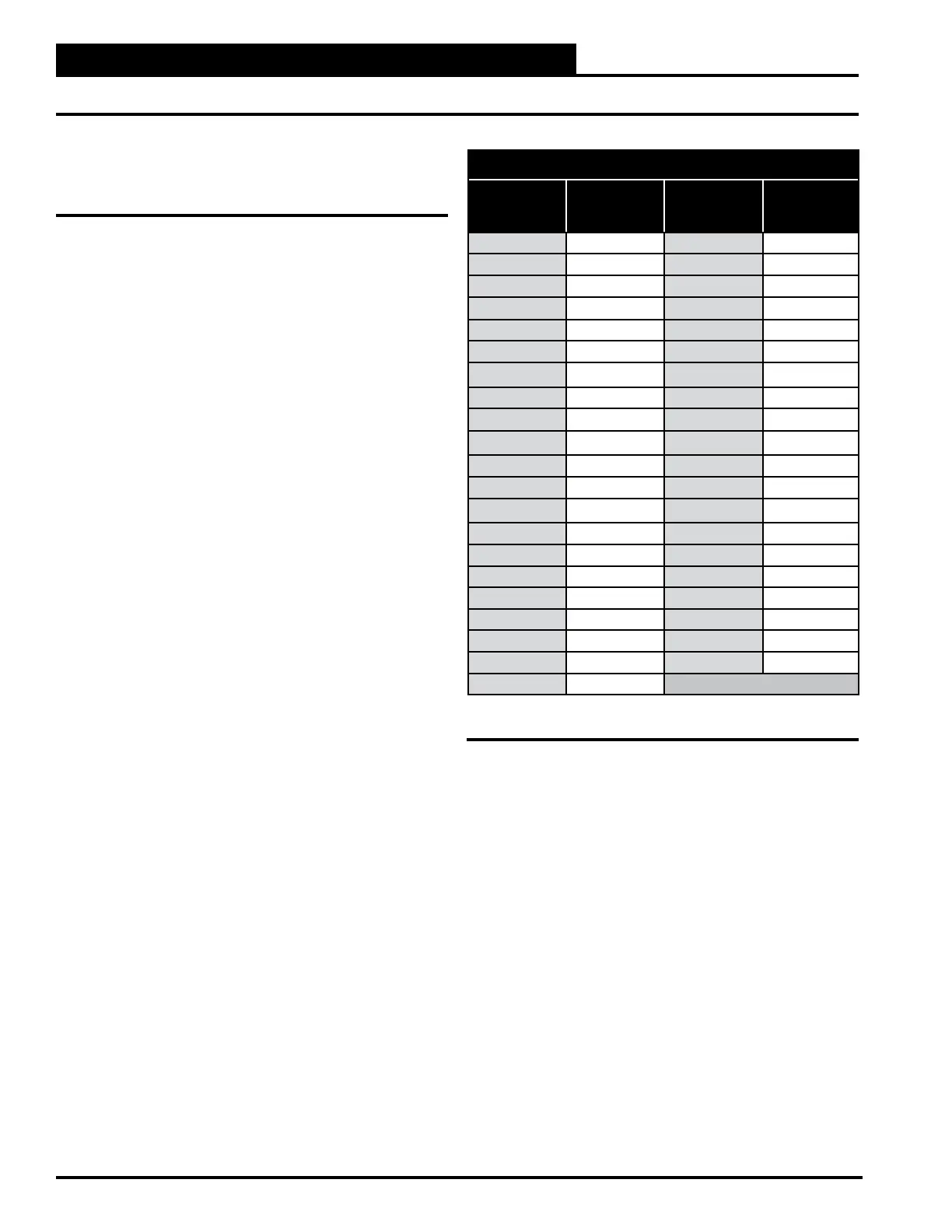

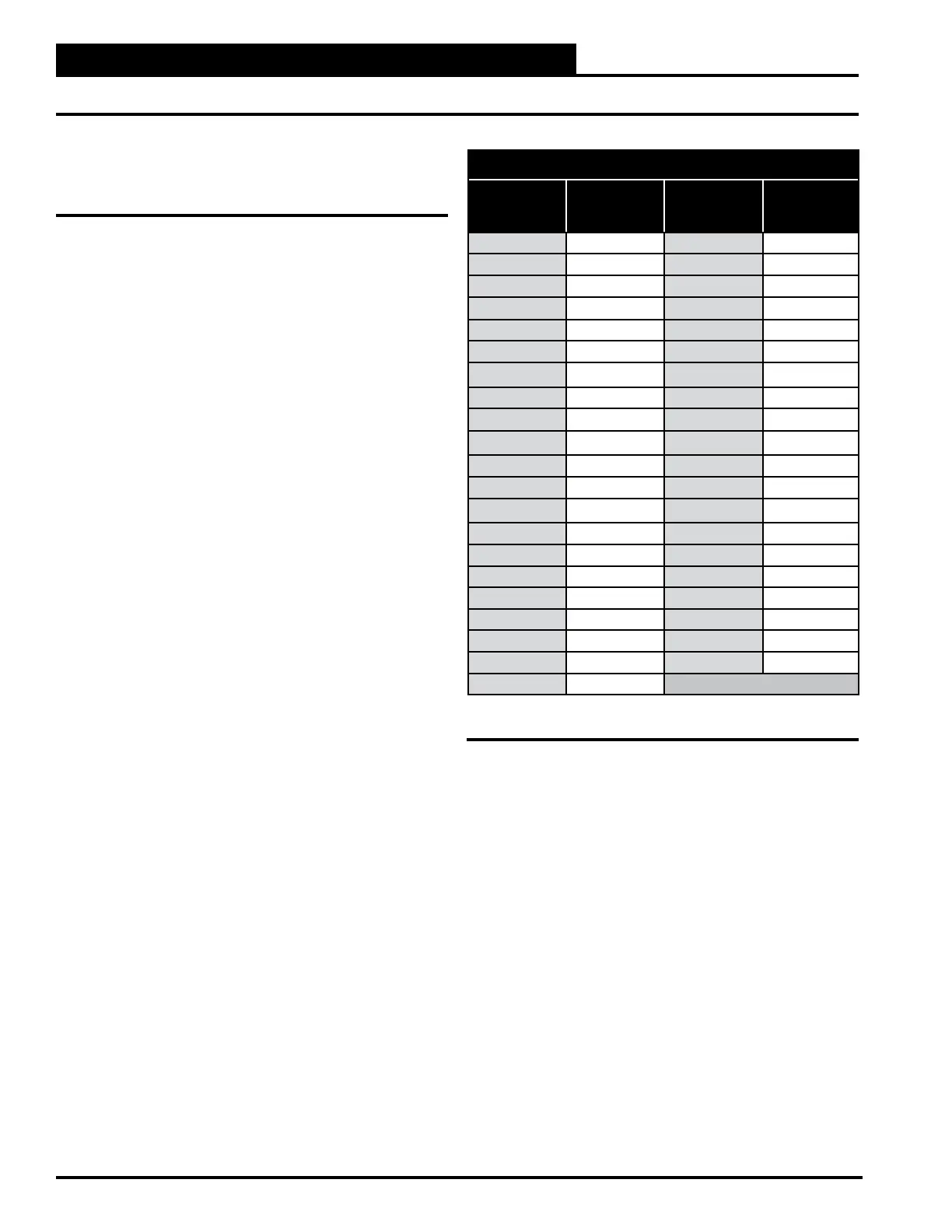

Table 9: 0-667 psi Transducer Chart

0-667 psi Transducer Chart

Voltage Pressure Voltage Pressure

0.5 0 2.6 350

0.6 17 2.7 367

0.7 33 2.8 384

0.8 50 2.9 400

0.9 67 3.0 417

1.0 83 3.1 434

1.1 100 3.2 450

1.2 117 3.3 467

1.3 133 3.4 484

1.4 150 3.5 500

1.5 167 3.6 517

1.6 183 3.7 534

1.7 200 3.8 550

1.8 217 3.9 567

1.9 233 4.0 584

2.0 250 4.1 600

2.1 267 4.2 617

2.2 283 4.3 634

2.3 300 4.4 650

2.4 317 4.5 667

2.5 334

Liquid Line Pressure Transducer and

Head Pressure Transducer Testing

0-667 psi

Liquid Line Pressure Transducer Testing

The Liquid Line Pressure is obtained by using the Liquid Line

Pressure Transducer, which is connected into the Liquid Line

of the compressor.

Use the voltage column to check the Liquid Line Pressure

Transducer while connected to the Subcool Monitor Module. The

module must be powered for this test. Read voltage with a meter

set on DC volts. Place the positive lead from the meter on the

SIG input terminal located on the module. Place the negative lead

from the meter on the ground (GND) terminal located adjacent

to the SIG terminal on the module. Use a refrigerant gauge set

to measure the suction line pressure near where the Liquid Line

Pressure Transducer is connected to the discharge line. Measure

the voltage at the SIG and GND terminals and compare it to the

appropriate chart depending on the refrigerant you are using. If

the pressure/voltage readings do not align closely with the chart,

your Liquid Line Pressure Transducer is probably defective and

will need to be replaced.

Head Pressure Transducer Testing

Use the voltage column to check the Head Pressure Transducer

while connected to the RSMZ Module. The module must be

powered for this test. Read voltage with a meter set on DC volts.

Place the positive lead from the meter on the HP input terminal

located on the module. Place the negative lead from the meter on

the ground (GND) terminal located adjacent to the HP terminal

on the module. Use a refrigerant gauge set to measure the line

pressure near where the Head Pressure Transducer is connected

to the condenser. Measure the voltage at the HP and GND

terminals and compare it to the appropriate chart depending on

the refrigerant you are using. If the pressure/voltage readings do

not align closely with the chart, your Head Pressure Transducer

is probably defective and will need to be replaced.

Loading...

Loading...