Damping

Level transmitter output signals that are noisy as a result of the

process can be smoothed (damped) electrically. Damping is a

setting designed to delay the mA output response to a change

in measured level.

Different scenarios require different damping settings:

• If the process is agitated or splashing of the liquid is possible,

a higher damping value may be required.

• If the process changes rapidly, a lower damping value may be

needed to increase the response time to a level change.

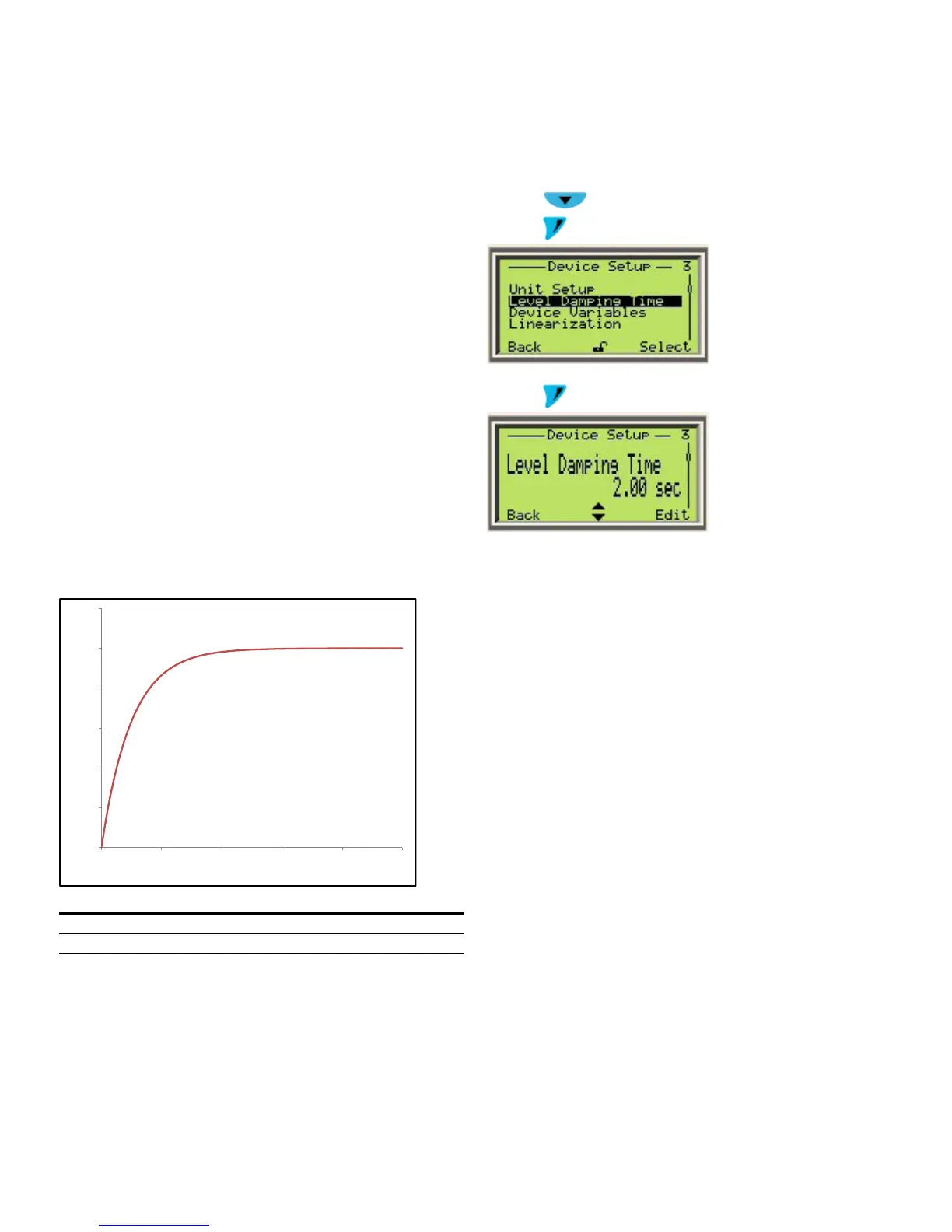

Damping can be described as the time responsiveness of the

device to the change in measured level. The relationship

between damping to changes in input can be described in the

following formula where A equals change in measurement

From this equation a table and graph can be derived to

illustrate the delay in reaction time due to changes in the

damping value

0

0.2

0.4

0.6

0.8

1

1.2

0 2 4 6 8 10

Fraction of amplitude change

Response time in multiples of damping input value

Time Multiplier

% of Input Value

Figure 29 Damping

The additional time constant can be set between 0.1 seconds

and 60 seconds in increments of 0.1 seconds. Damping does

not affect the value shown on the digital display as a physical

unit. Damping only affects the parameters derived from it, such

as analog output current, free-process variable, input signal for

the controller and so forth. The damping adjustment can be

performed through the HMI display or handheld terminal.

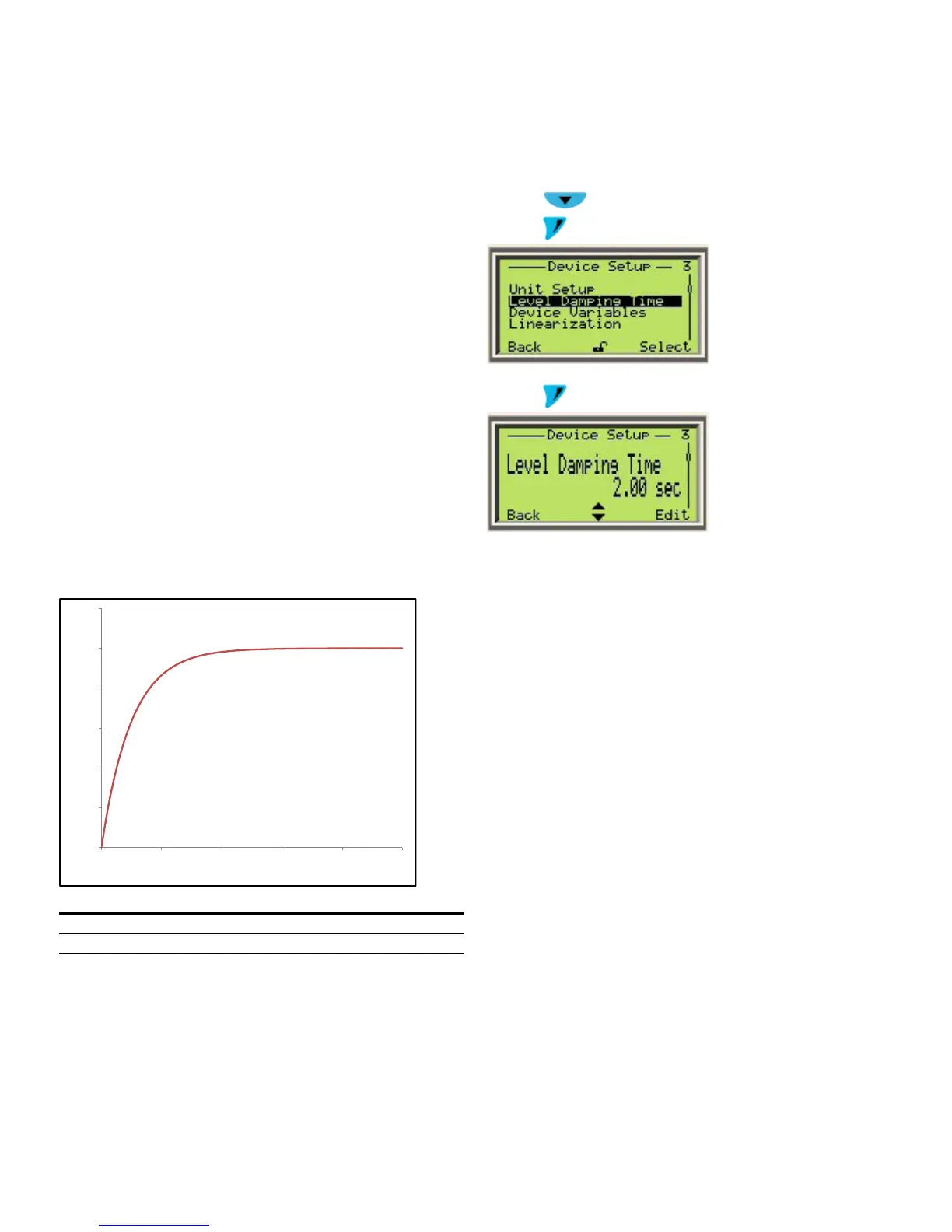

Adjusting damping settings through HMI display

1 Enter the menu: Device Setup

2 Press

to select Level Damping Time

3 Press

to confirm the selection

4 Press to edit the Level Damping Time

Overview of the linearization/strapping tables

Linearization is an approximation to a function at a given point.

The LMT has 21 linearization points available for implementing

up to 20 segments of linear calibration.

Linearization allows significant improvements of measurement

accuracy in tanks and vessels with irregular shapes. If

linearization were not used in these cases, the resulting level

calculation would not meet the expected accuracy due to the

non-linear function between the level in the tank and the

calculated level.

For effective use of the multipoint calibration using

linearization tables, it is important to understand the

advantages that it provides and the limitation of its use.

Typically, there is a need for linearization/strapping tables in

the following scenario:

• The user intends to use Volume or Flow as the Output Type.

• The tank or vessel is irregularly shaped and the function

between the level in the tank and the calculated level is non-

linear.

Practical use of linearization/strapping table

Assume that Volume will be used as the Output Type in the

tanks shown in Figure 28 below. For these tanks, only two

points need to be enabled in the linearization/strapping table.

The reason for this is that the Volume is a linear function of the

Level being measured. In both cases, the volume is equal to the

factor of the area of the base of the tank by the liquid level.

Loading...

Loading...