Ex relevant specifications for operation in Div. 2

SM/FEX300/FEX500/FM/CSA-EN FEX300, FEX500 EN - 29

6 Ex relevant specifications for operation in Div. 2

6.1 Electrical connection

6.1.1 Flowmeter sensor and transmitter in Div. 2, or transmitter outside the hazardous area

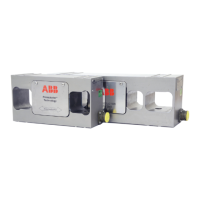

FEP315 / FEP515, FEH315 / FEH515, FEP325 / FEP525, FEH325 / FEH525 flowmeter

sensors and FET325 / FET525 transmitters (Div. 2)

FET321 / FET521 transmitter outside the

hazardous area

A = Transmitter, B= Sensor

Fig. 15: HART, PROFIBUS PA and FOUNDATION fieldbus protocol

Change from one to two colu mns

Power supply connections

AC power supply

Terminal Function / Notes

L

Live / Phase

N

Neutral

PE /

Protective earth (PE)

DC power supply

Terminal Function / Notes

1+

+

2-

-

PE /

Protective earth (PE)

Sensor cable terminal connections

Only on remote mount design.

Terminal Function / Notes Wire color

M1

Magnet coil Brown

M2

Magnet coil Red

D1

Data line Orange

D2

Data line Yellow

/ SE

Shield -

E1

Signal line Violet

1S

Schield for E1 -

E2

Signal line Blue

2S

Schield for E2 -

3

Measurement potential Green

Output connections

Terminal Function / Notes

31 / 32

Current / HART output

The current output is available in "active" or "passive"

mode.

97 / 98

Digital communication

PROFIBUS PA (PA+ / PA-) or FOUNDATION

fieldbus (FF+ / FF-) in acc. with IEC 61158-2.

51 / 52

Digital output DO1 active / passive

Function can be configured locally as „Pulse Output"

or „Digital Output". Factory setting is „Pulse Output".

81 / 82

Digital input / contact input

Function can be configured locally as „External

output switch-off“, „external totalizer reset“, „external

totalizer stop“ or „other“.

41 / 42

Digital output DO2 passive

Function can be configured locally as „Pulse Output"

or „Digital Output". Factory setting is „Digital Output",

flow direction signaling.

PA

Potential Equalization (PA)

Functional ground

(only for transmitter outside the hazardous area)

Change from one to two colu mns

Change from one to two colu mns

Note

The housing for the transmitter and flowmeter sensor must be

connected to the potential equalization PA. The operator must ensure

that when connecting the protective conductor (PE) no potential

differences can occur between protective conductor and potential

equalization (PA).

FM-compliant installations must be performed in accordance with

"Installation of Intrinsically Safe Systems for Hazardous (Classified)

Locations" (ANSI/ISA RP 12.6) and "National Electric Code®"

(ANSI/NFPA 70 Sections 504 and 505).

For devices with remote mount design for use in FM / cFM Div. 1 or

FM / cFM Div. 2 the signal cable between the flowmeter sensor and

the transmitter must have a minimum length of 5 m (16.4 ft).

A temperature of 70 °C (158 °F) at the cable entry is assumed for the

Ex calculations. Therefore, the cables used for the supply power and

the signal inputs and outputs must have a minimum specification of

70 °C (158 °F).

Change from one to two colu mns

G00873-02

PA

31 32

A

24 V

51 52 81 82

41 42

LN

1+ 2-

M1 M2 D1 D2

3

2S

E2 E1

1S

M1 M2 D1 D2

3

E2 E1

B

PE

PA

97 98

41 42

PA+ PA-

FF+ FF-

+

-

+

-

+

-

+

-

+

-

HART

PROFIBUS PA, FOUNDATION fieldbus

PA /

2S 1S

PA

PA

PA

FEP315 /

FEP515

FEP325 / FEP525

FEH325 / FEH525 FET325 / FET525 FET321 / FET521

PA

FEH315 /

FEH515

Loading...

Loading...