18 CI/FSS/FSV430/450-EN Rev. D | SwirlMaster FSS430, FSS450 VortexMaster FSV430, FSV450

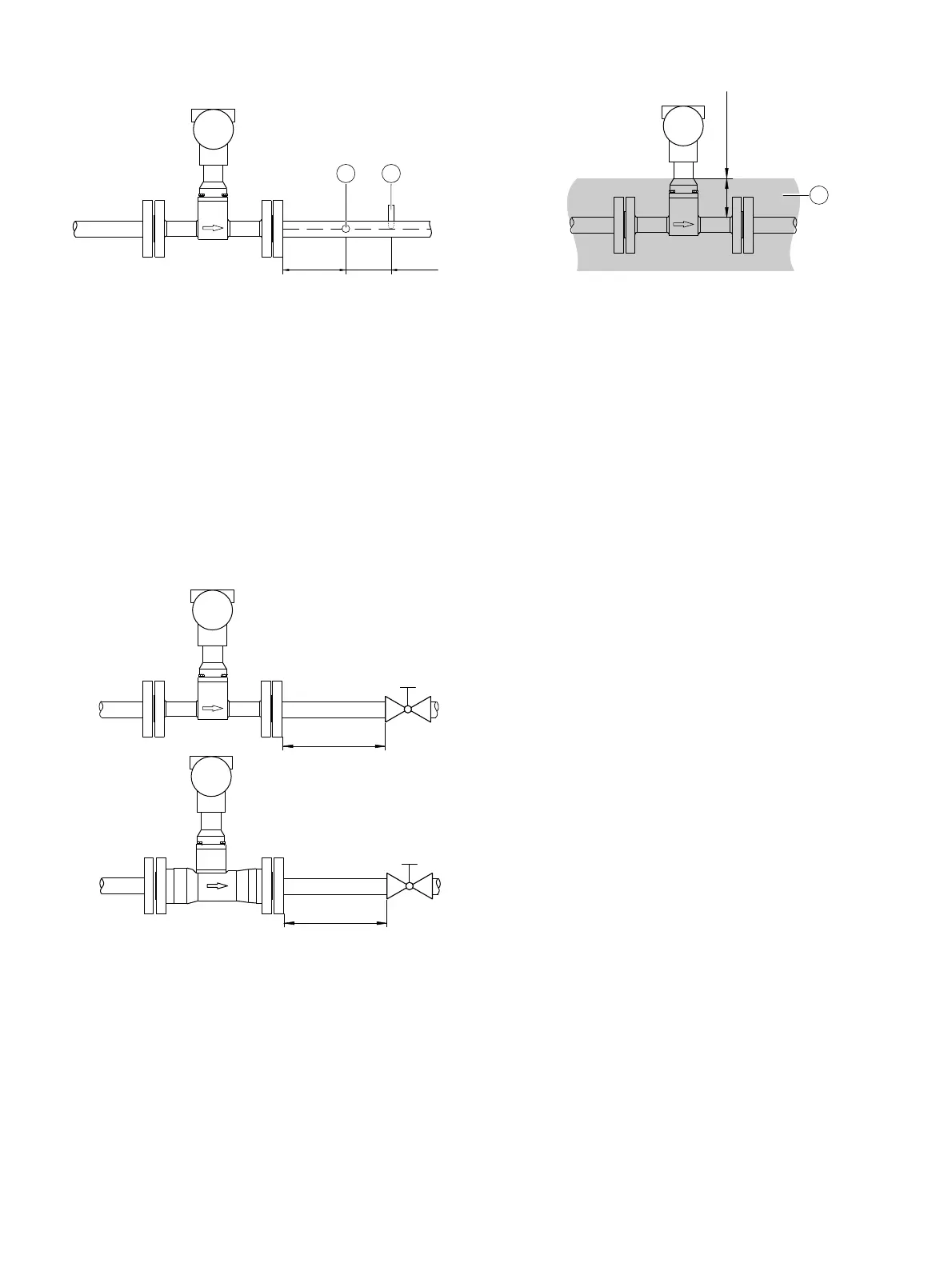

5.1.4 Installation for external pressure and temperature

measurement

Fig. 11: Arrangement of the temperature and pressure measuring

points

1 Pressure measuring point 2 Temperature measuring point

As an option, the flowmeter can be fitted with a Pt100 for

direct temperature measurement. This temperature

measurement enables, for example, the monitoring of the

measuring medium temperature or the direct measurement of

saturated steam in mass flow units.

If pressure and temperature are to be compensated externally

(e.g. with the flow computer unit), the measuring points must

be installed as illustrated.

5.1.5 Installation of final controlling equipment

Fig. 12: Installation of final controlling equipment

Final controlling equipment must be arranged at the outflow

end spaced at a minimum 5 x DN. If the measuring medium is

conveyed through piston pumps / plunger pumps or

compressors (pressures for fluids > 10 bar [145 psi]), it may

be subject to hydraulic vibration in the piping when the valve is

closed. If this does occur, it is essential that the valve be

installed in the flow direction upstream of the flowmeter. The

SwirlMaster FSS400 is particularly well suited for such

arrangements. Suitable damping devices (such as air vessels if

using a compressor for conveying) may need to be used.

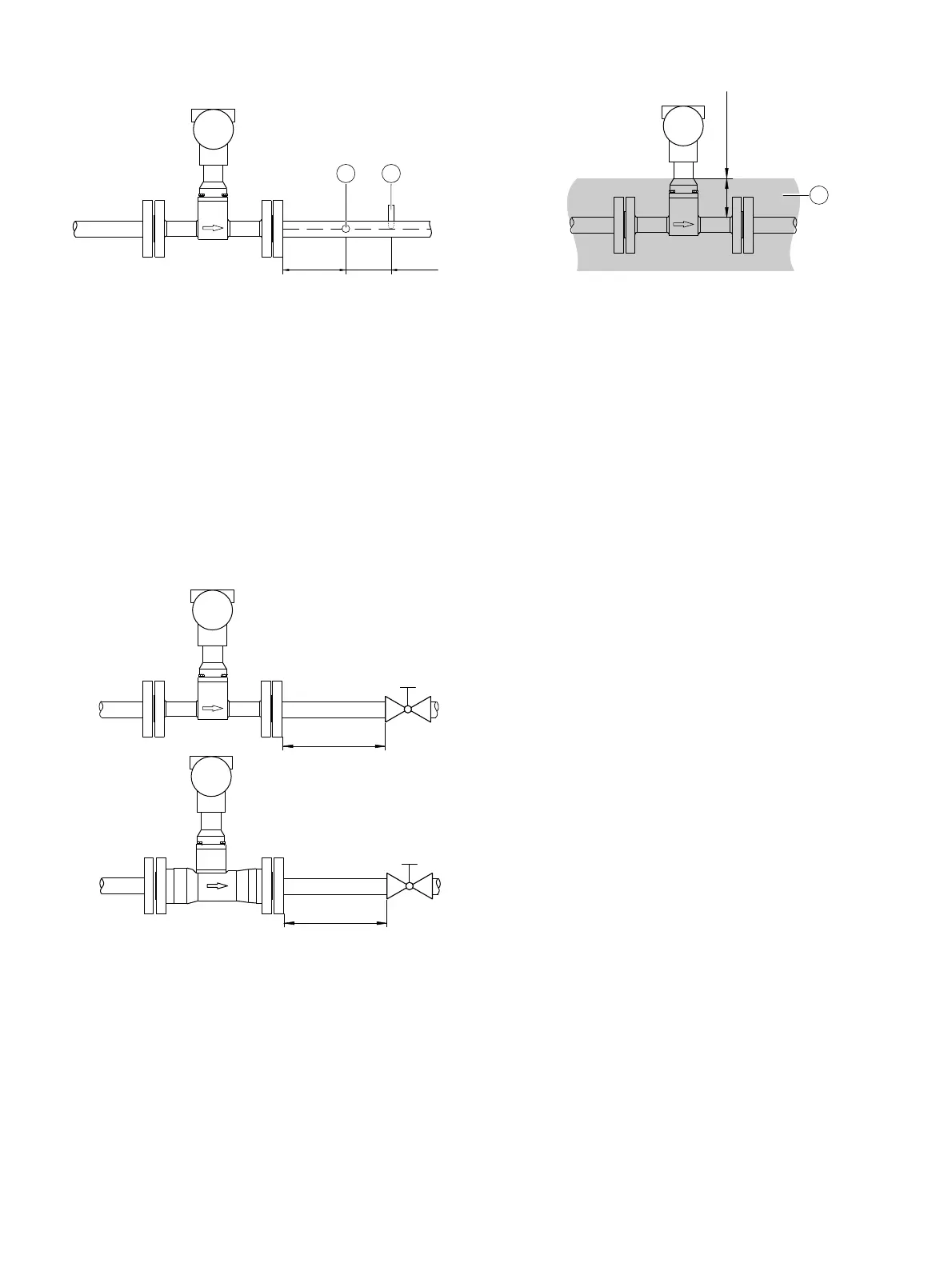

5.1.6 Sensor insulation

Fig. 13: Insulation of the meter tube

1 Insulation

The piping can be insulated up to a thickness of 100 mm

(4 inch).

5.1.7 Use of trace heating

Trace heating may be used under the following conditions:

— If it is installed directly on or around the piping

— If, in the case of existing pipeline insulation, it is installed

inside the insulation (the maximum thickness of

100 mm [4 inch] must not be exceeded)

— If the maximum temperature the trace heating is able to

produce is less than or equal to the maximum medium

temperature.

NOTE

The installation requirements set out in EN 60079-14 must be

observed.

Please note that the use of trace heaters will not impair EMC

protection or generate additional vibrations.

G11756

1

2

3...5xDN 2...3xDN

≥5 x DN

≥5 x DN

FSS400

FSV400

G11761

≤ 100 mm (4")

1

G11762

Loading...

Loading...