SwirlMaster FSS430, FSS450 VortexMaster FSV430, FSV450 | CI/FSS/FSV430/450-EN Rev. D 19

5.2 Installing the sensor

Observe the following points during installation:

— The flow direction must correspond to the marking, if

present

— The maximum torque for all flanged connections must be

observed

— The devices must be installed without mechanical tension

(torsion, bending)

— Wafer type devices with plane parallel counterflanges may

only be installed with suitable gaskets

— Only gaskets made from a material that is compatible with

the measuring medium and measuring medium

temperature may be used

— The piping may not exert any inadmissible forces or

torques on the device

— Do not remove the sealing plugs in the cable glands until

you are ready to install the electrical leads

— Make sure the gaskets for the housing cover are seated

correctly Carefully seal the cover. Tighten the cover fittings

— Do not expose the transmitter to direct sunlight and

provide for appropriate sun protection where necessary

— When selecting the installation site, make sure that

moisture cannot penetrate the terminal or transmitter

compartment

The device can be installed at any location in a pipeline under

consideration of the installation conditions.

1. Position the meter tube coplanar and centered between

the piping.

2. Install gaskets between the sealing surfaces.

NOTE

For achieve the best results, ensure the gaskets fit

concentrically with the meter tube

To ensure that the flow profile is not distorted, the gaskets

must not protrude into the piping.

3. Use the appropriate screws for the holes.

4. Slightly grease the threaded nuts.

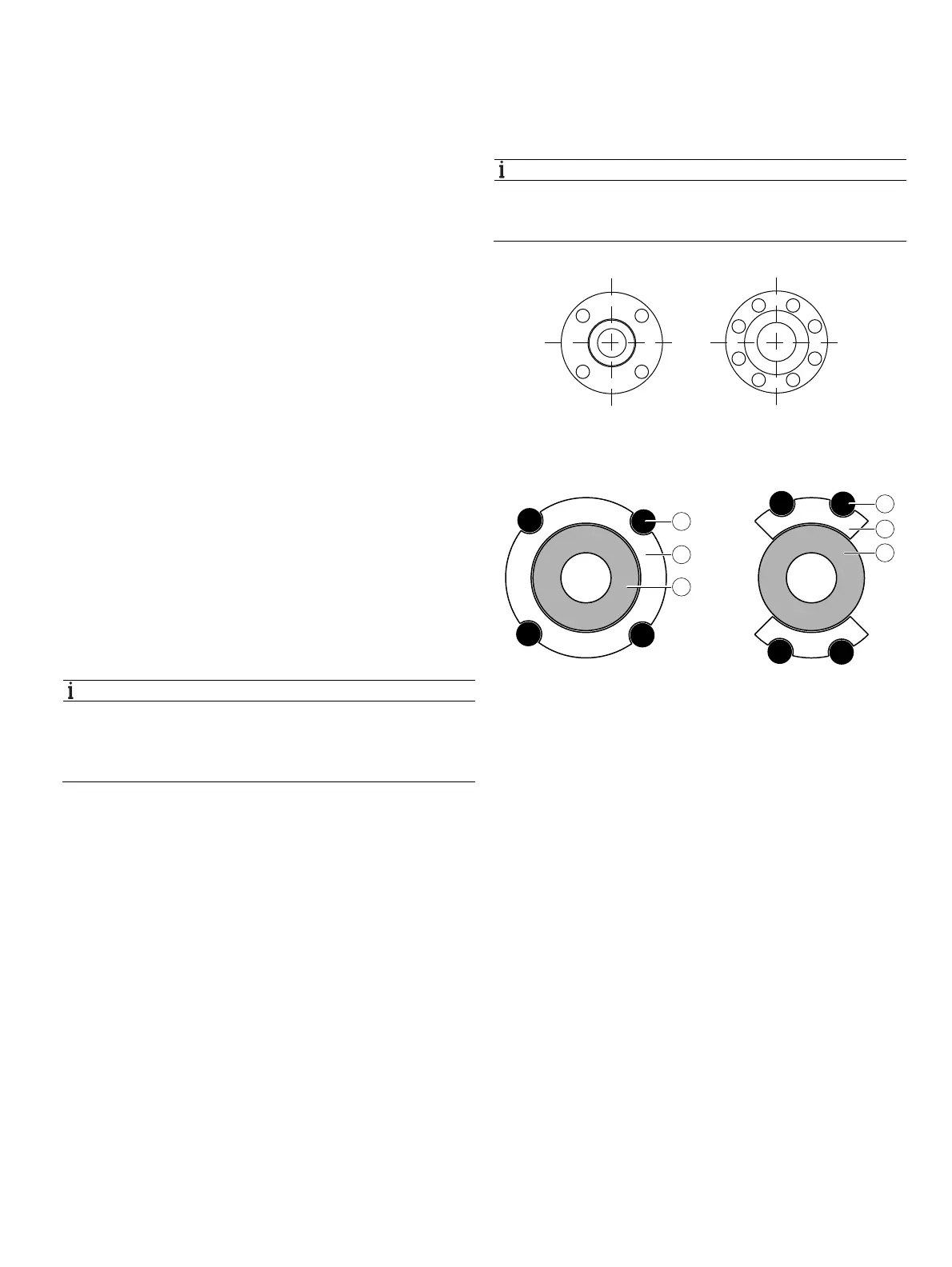

5. Tighten the nuts in a crosswise manner as shown in the

figure. First tighten the nuts to approx. 50 % of the

maximum torque, then to 80 %, and finally a third time to

the maximum torque.

NOTE

Torques for screws depend on temperature, pressure, screw

and gasket materials. The relevant applicable regulations

must be taken into consideration.

Fig. 14: Tightening sequence for the flange screws

5.2.1 Centering the wafer type design

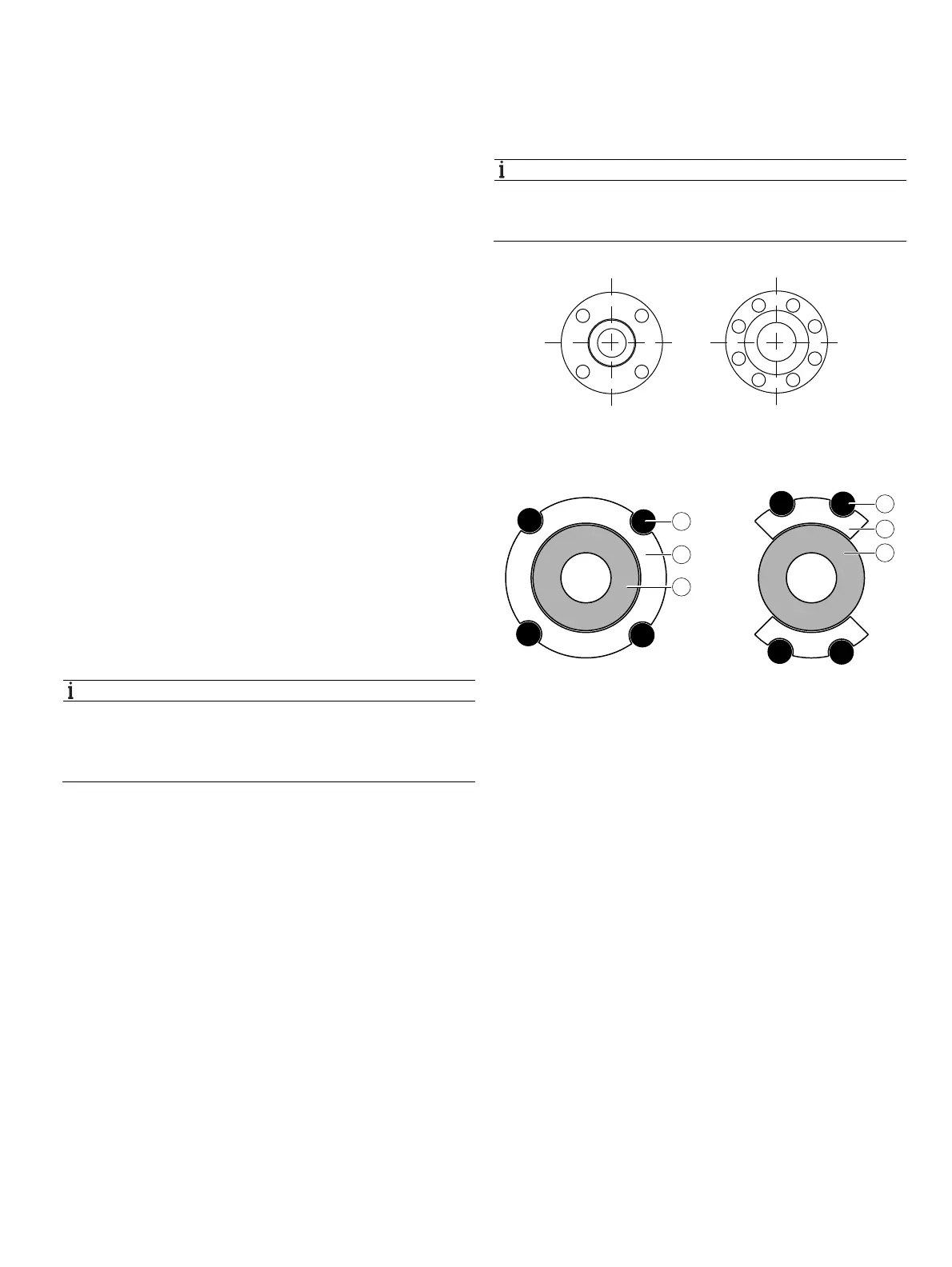

Fig. 15: Centering the wafer type design with the ring or segment

1 Bolt 2 Centering ring 3 Meter tube (wafer type)

4 Centering segment

Wafer type devices (FV400 only) are centered via the outside

diameter of the flowmeter sensor body with the corresponding

bolts.

Depending on the nominal pressure rating, sleeves for the

bolts, a centering ring (up to DN 80 [3"]) or segments can be

ordered as additional accessories.

G11726

1

2

7

8

5

3

4

6

1

2

3

4

G11763

1

2

3

1

4

3

Loading...

Loading...