21

4. Dispatch and storage

4.1 Condition on delivery

At the time of dispatch, the UniGear ZS1 panels are factory-assembled, the withdrawable parts are

in the test position and the doors are closed.

The factory-assembled panels are checked at the works for completeness in terms of the order and

simultaneously subjected to routine testing (normally without AC voltage testing of the busbars)

according to IEC publication 62271-200, and are therefore tested for correct structure and function.

The busbars are not assembled. The busbar material, fasteners and accessories are packed

separately.

4.2 Packing

According to the kind of transport and country of destination, the panels remain unpacked or are welded

in foil and packed in seaworthy crates. A drying agent is provided to protect them against moisture:

• Panels with basic packing or without packing;

• Panels with seaworthy or similar packing (including packing for container shipments):

- Sealed in polyethylene sheeting;

- Transport drying agent bags included;

- Moisture indicator included;

• Observe the directions for use of the drying agent bags. The following applies:

- Coloured indicator blue: contents dry;

- Coloured indicator pink: contents moist (relative humidity above 40%).

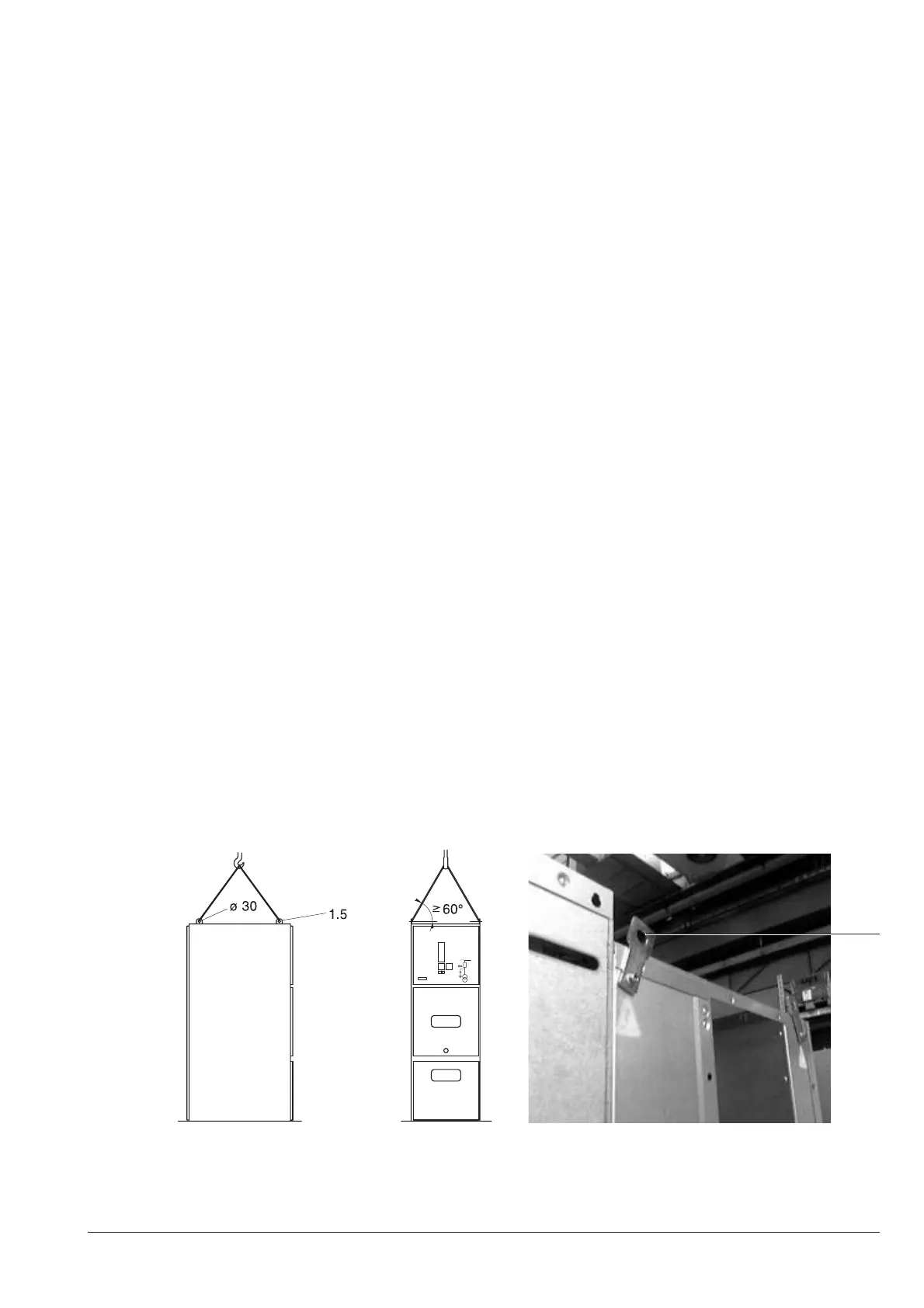

4.3 Transport

The transport units normally comprise individual panels and, in exceptional cases, small groups of

panels. The panels are each fitted with four lifting eyebolts.

Transport panels upright. Take the high centre of gravity into account. Only ever carry out loading

operations when it has been ensured that all precautionary measures to protect personnel and

materials have been taken and use the following:

• Crane;

• Fork-lift truck and/or;

• Manual trolley jack.

Loading by crane:

• Fit lifting ropes of appropriate load capacity with spring catches (eyebolt diameter: 30 mm);

• Keep an angle of at least 60° from the horizontal for the ropes leading to the crane hook;

• Hang the unit using ALL four eyebolts!

For detailed information on switchgear handling, please refer to chapter 4.6.

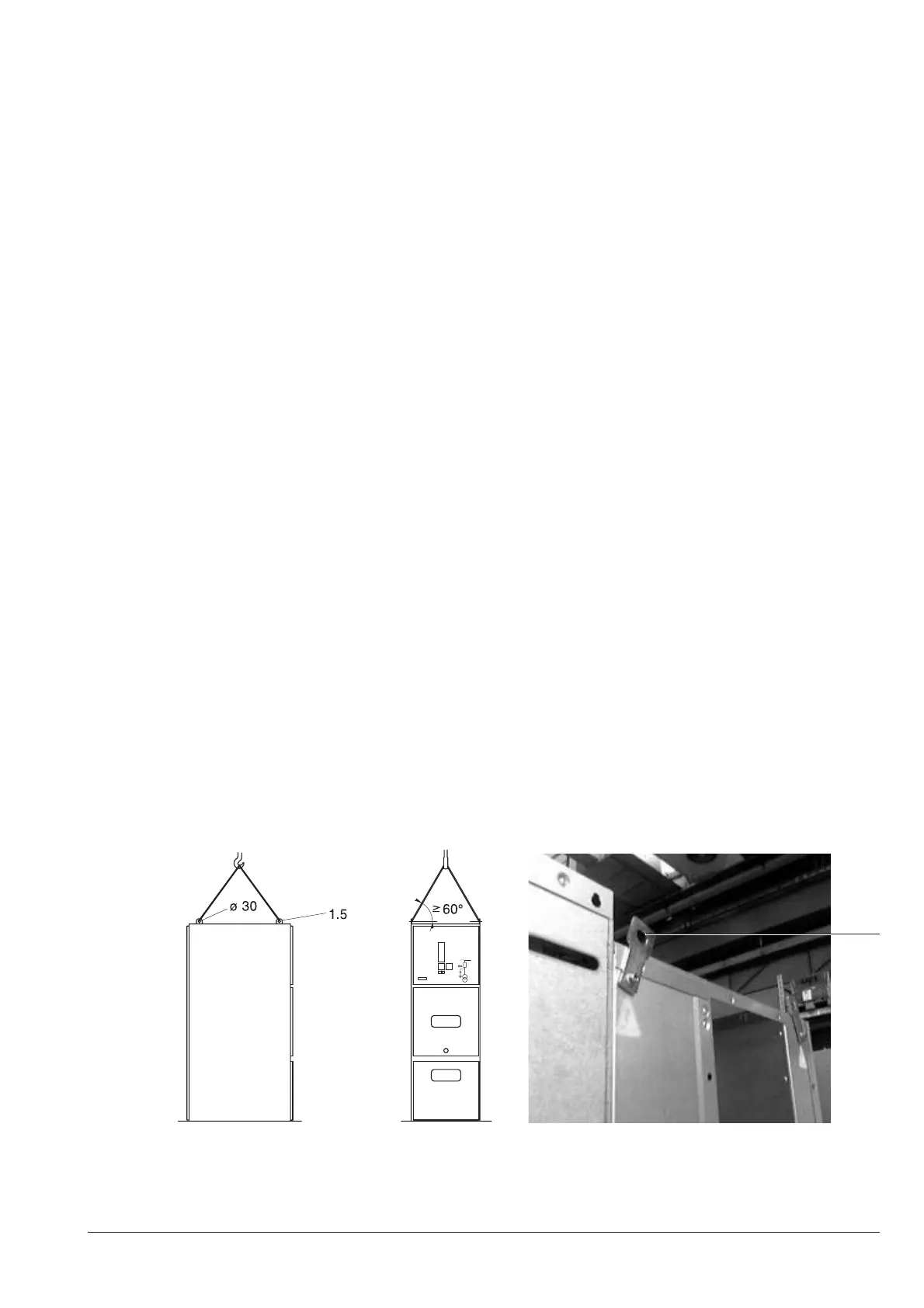

Figure 29: Handling by crane

1.5 lifting eyebolt

1.5

Loading...

Loading...