36

80

Æ 16

80

Æ 16

M 12

M 12

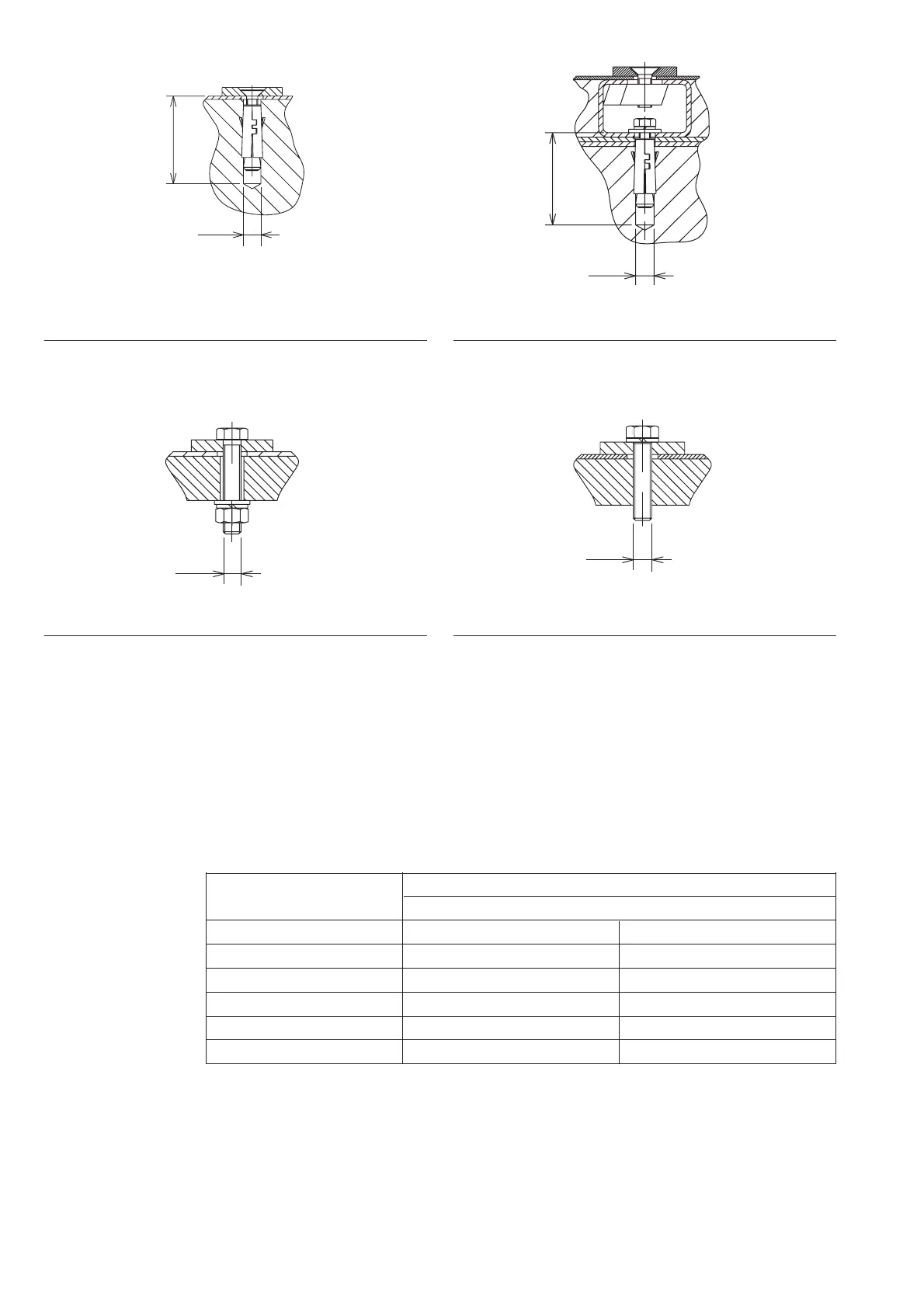

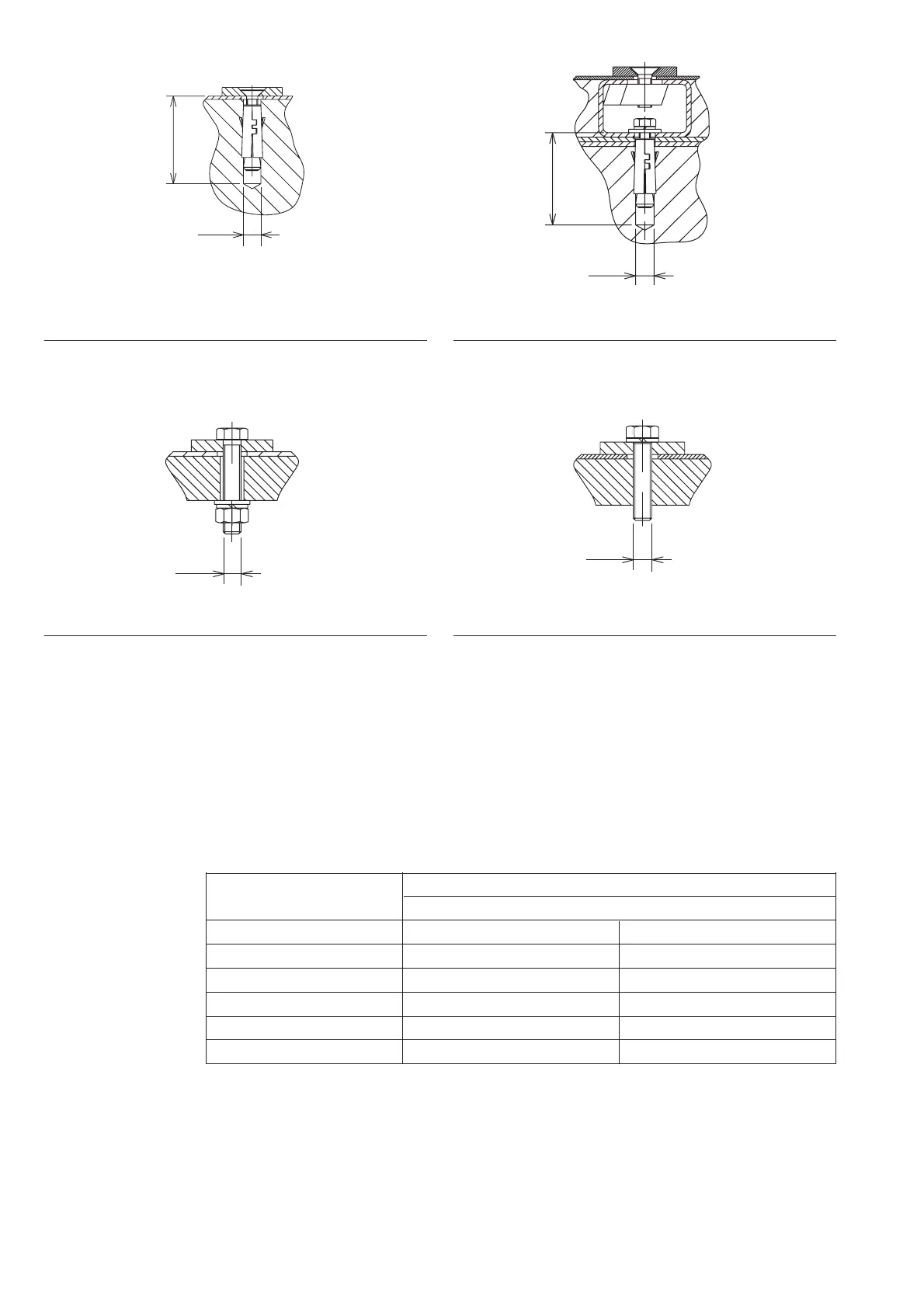

Figure 57: Through hole on metal structure Figure 58: Threaded hole on metal structure

Figure 55: Anchoring bolts on concrete floor Figure 56: Base irons on concrete floor

5.3 Assembly of the switchgear panels

Use screws of tensile class 8.8. The tightening torques for the busbar screw connections with dished

washer are as follows:

Any tightening torques which deviate from those in the general table (e.g. for contact systems or device

terminals) must be taken into account as stated in the detailed technical documentation.

It is recommended that the threads and head contact surfaces of bolts should be lightly oiled or

greased, so as to achieve a precise rated tightening torque.

Recommended tightening torque

1) 2)

Nm

Lubricant

3)

Thread Without Oil or grease

M6 10.5 4.5

M8 26 10

M10 44.1 20

M12 74.6 40

M16 165 80

1)

The rated tightening torques for fasteners without lubrication are based on a coefficient of friction for the thread of 0.14 (the actual

values are subject to an unavoidable range, in part not inconsiderable).

2)

Rated tightening torques for fasteners with lubrication in accordance with DIN 43 673 Standard .

3)

Thread and head contact surface lubricated.

Loading...

Loading...