27

5. Assembly of the switchgear on site

In order to obtain an optimum installation sequence and ensure high quality standards, site installation

of the switchgear should only be carried out by specially trained and skilled personnel, or at least by

personnel supervised and monitored by responsible persons.

5.1 General site requirements

On commencement of installation on site, the switchgear room must be completely finished, provided

with lighting and the electricity supply, lockable, dry and with facilities for ventilation. All the necessary

preparations, such as wall openings, ducts, etc., for laying the power and control cables up to the

switchgear must already be completed. Where switchgear panels have top-mounted structures for

earthing switches or instrument transformers, it must be ensured that the ceiling height is sufficient

for the opening travel of the pressure relief plates.

The ceiling must be high enough for assembly of pressure relief duct and/or top-mounted VT box and

earthing switch box.

Compliance with the conditions for indoor switchgear according to IEC 60694, including the conditions

for the “minus 5 indoor” temperature class must be ensured.

5.2 Foundations

The following 3 basic installation methods of switchgear in the switchroom are distinguished:

Method A – installation on the base irons of “C” profile shape

As standard it is recommended to install the switchgear on the base irons of “C” profile shape set into

the concrete floor of switchroom. In this case the units are fastened using the special bolt blocks (ABB

delivers by request).

Method B – installation on the levelled concrete floor

Installation directly on the levelled concrete floor makes much higher demands on the floor levelling,

which must, in this case, fulfill the same tolerances as the base irons during installation method A.

The fastening is carried out by means of anchoring bolts in the concrete floor.

Method C – installation on the raised false floor

In this case fastening of units is carried out by welding of outside panels to the steel floor frame in the

place where the frame exceeds the switchgear bottom, this means on the outside lateral walls of unit

row.

This method of installation is not recommended if seismic resistance is required.

Generally it is possible to recommend the following procedure of switchgear anchoring and

namely for any of the cited methods of installation:

1. The switchgear panels are bolted together in the front and rear part into one unit;

2. If seismic resistance is not required, it is not necessary to attach each switchgear panel to the floor

or frame, but it suffices to only fix outside panels in each row of switchgear;

3. If seismic resistance is required, it is necessary to attach each switchgear panel to the floor or frame.

To achieve seismic resistance the special fixing system is used. This system preferably makes use

of a steel floor frame with “C” profile shape but moreover with an additional special fixing element

– please contact the manufacturer for details.

Further given structural data guidelines given makes a rough calculation of the space required and

planning of the room design for a switchgear project.

When the final construction documents are compiled for execution of building, the binding

data supplied by ABB for a particular case must always be taken into account!

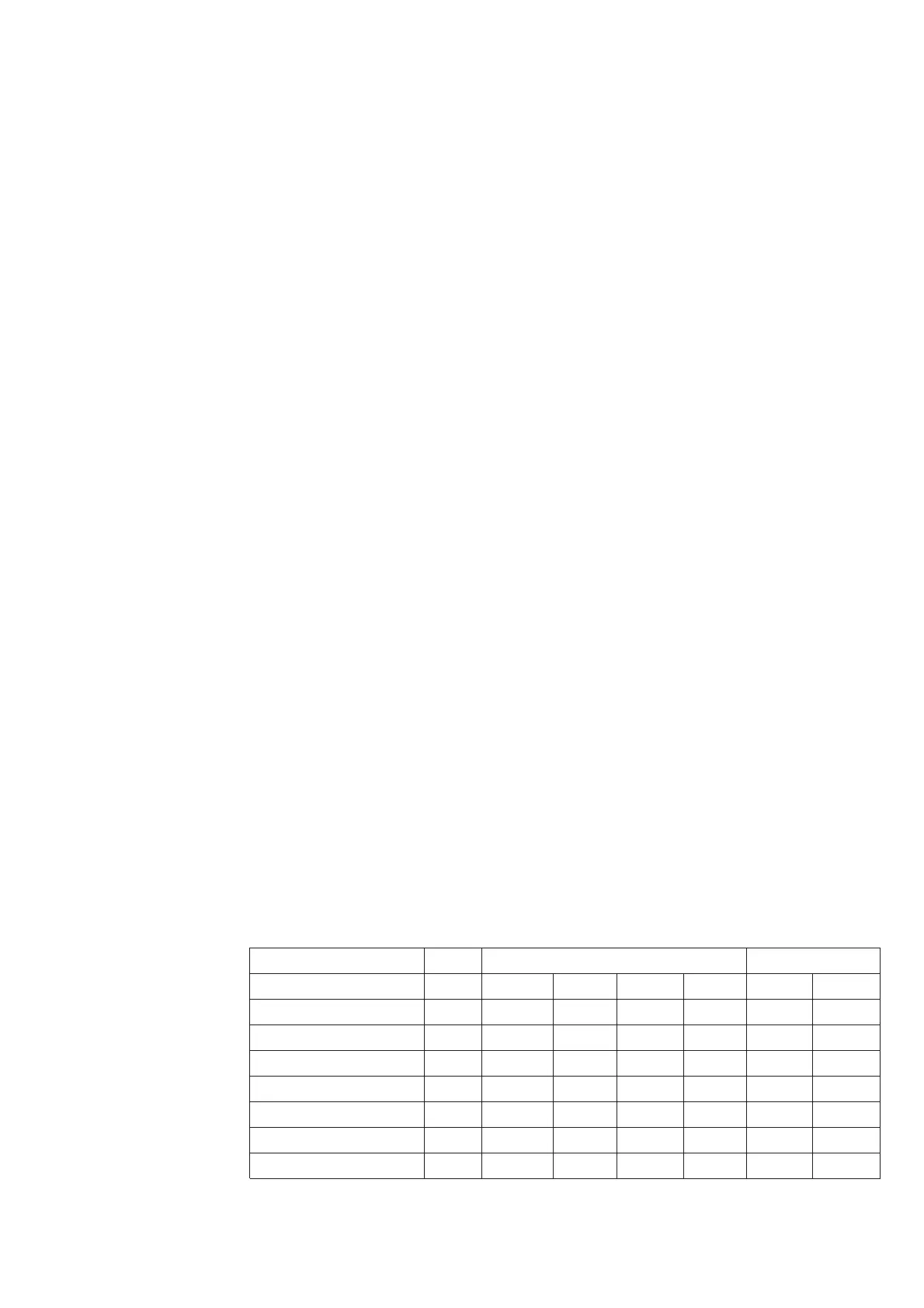

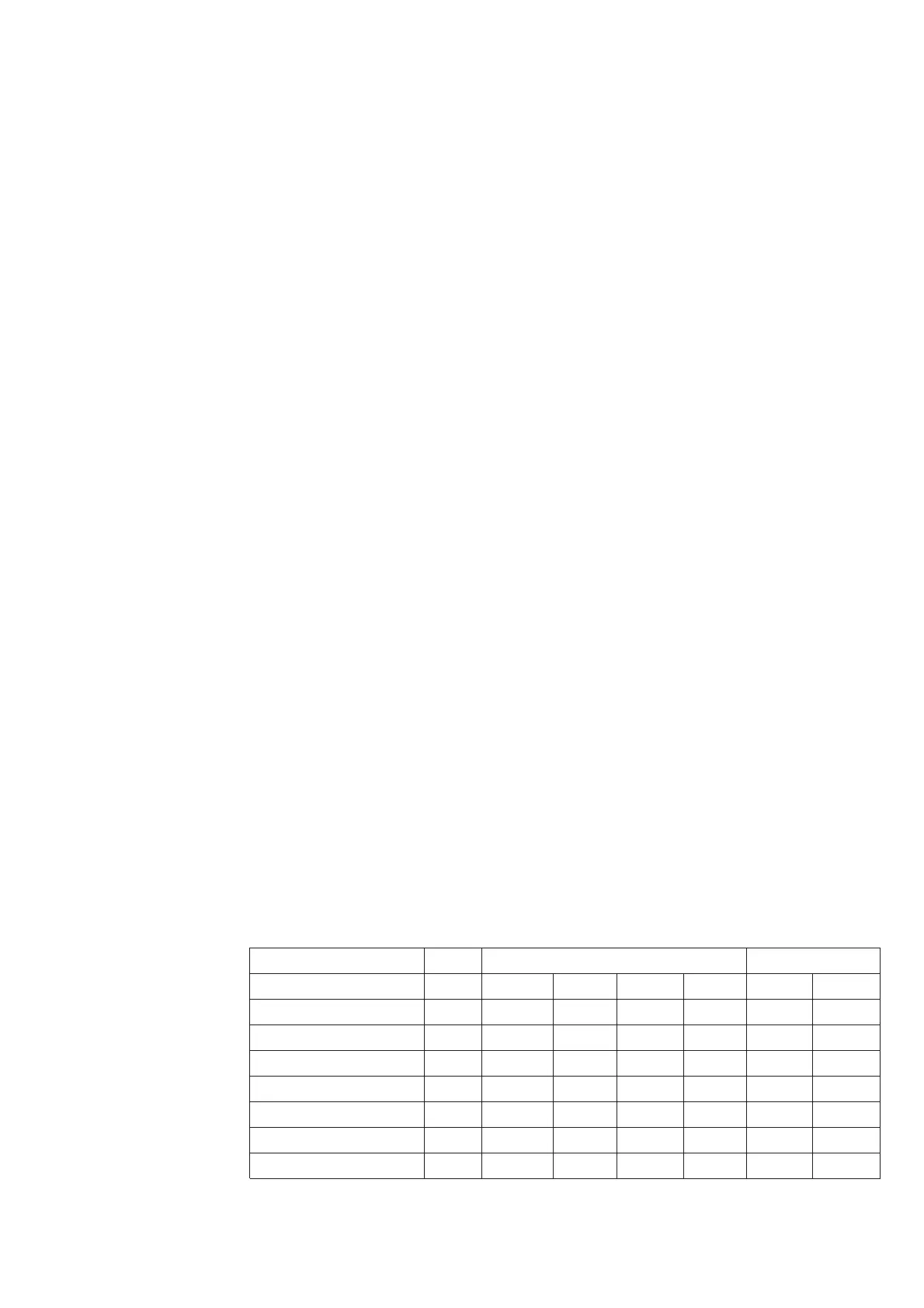

1)

Pay attention to appropriate national standards.

2)

Applies to low voltage compartments of standard height.

3)

Approximate numbers depending on the type of panels.

Dimension chart of structural data

Rated voltage kV 12/17.5 kV 24 kV

Panel width FT mm 550 650 800 1000 800 1000

Aisle width

1)

G mm 1350 1450 1600 1800 1500 1700

Door width mm 750 850 1000 1200 1000 1200

Door height

2)

mm 2400 2400 2400 2400 2525 2525

Assembly opening in ceiling:

Width mm 1000 1000 1000 1200 1000 1200

Length mm 1500 1500 1500 1500 1800 1800

Ceiling load

3)

kg/m

2

1200 1200 1400 1400 900 850

Loading...

Loading...