26

5 ELECTRIC CONNECTIONS

i

All electrical operations must

be performed BY STAFF WITH

NECESSARY LEGAL REQUISITES,

trained and informed regarding risks

correlated to these operations.

i

The features of the electric lines

and relative components must be

determined by STAFF QUALIFIED

FOR THE DESIGN OF ELECTRICAL

PLANTS, complying with national

and international regulations of the

place of installation of the unit.

i

All electrical connections must

comply with legislation in force at

the time of installation.

i

Reference must be made to the

wiring diagram supplied with the

appliance, for installation to be

performed correctly. The wiring

diagram, along with the manuals,

must be kept carefully and

made AVAILABLE FOR FUTURE

INTERVENTIONS ON THE UNIT.

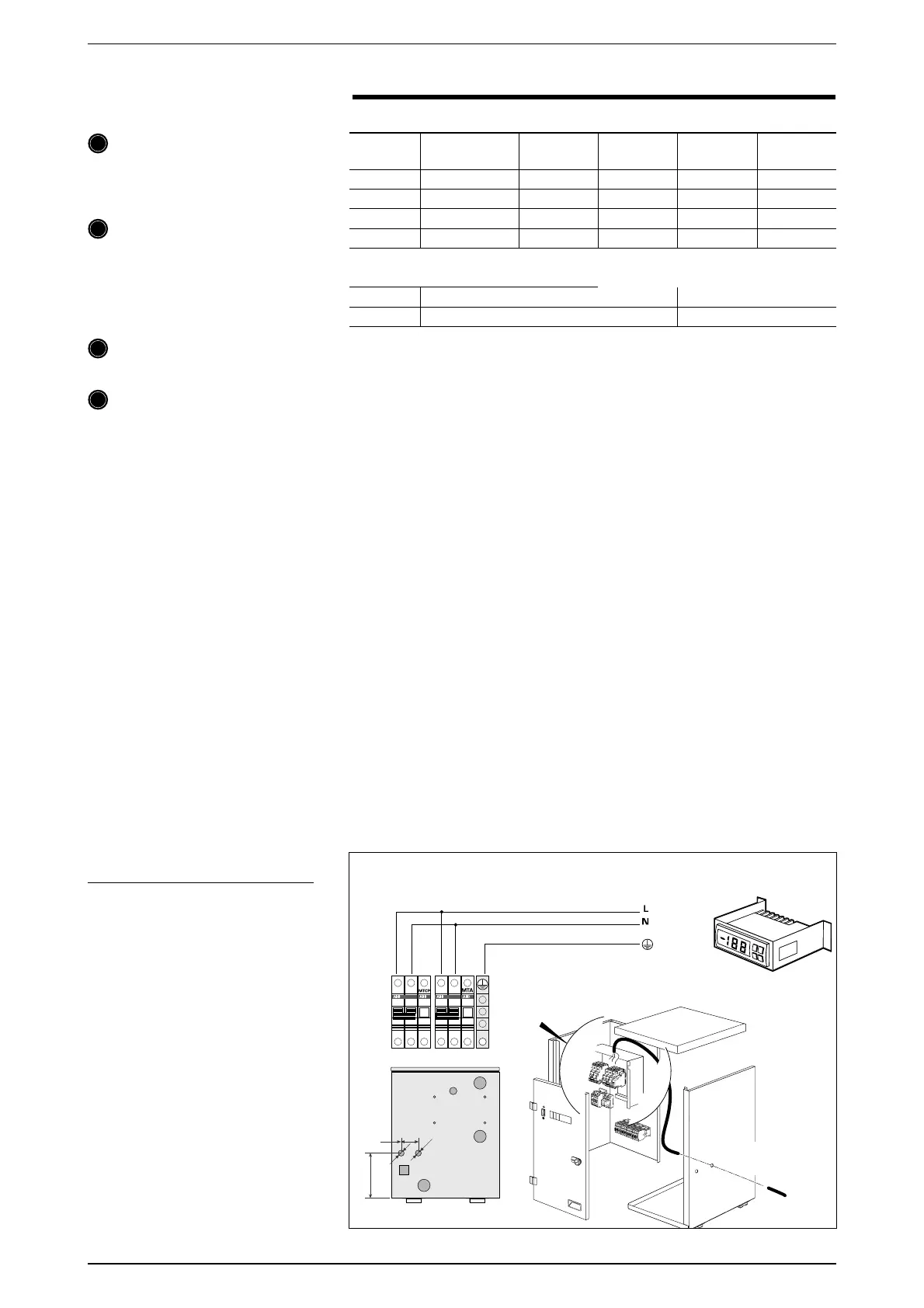

4.1 LINES AND UNIT ELECTRICAL

DATA

NOTE

The sections of the cables and

dimensioning of the line switch stated

in TAB 4.1.1 are purely indicative or

recommended for a maximum length of

50 m. It is the installer's responsibility to

appropriately dimension the power supply

line and the earth connection depending

on:

- the length

- the type of cable

- the absorption of the unit, physical

location and environmental

temperature.

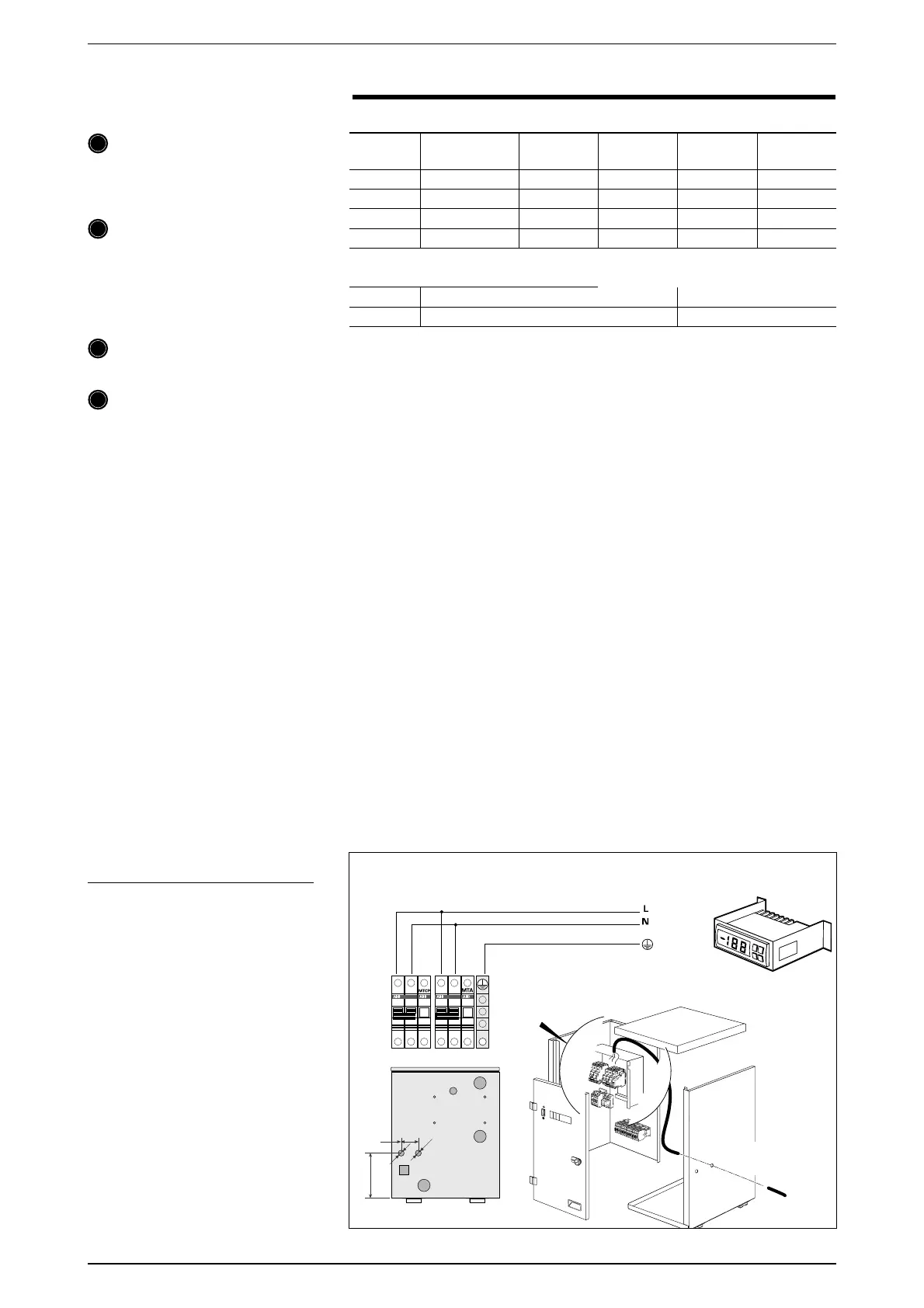

4.2 CONNECTION TO THE ELECTRIC

POWER SUPPLY MAINS

- Check that the electric power supply

line has features in compliance with

the potential that it must support.

- Protect the cables using fairleads with

suitable lengths.

-

The unit is completely wired in the

factory and requires an electric power

supply to be started-up according

to the indications on the unit's plate,

intercepted with line protections.

The units are prepared for electric

connections with fairleads on the right

side panel (fig. 01), one for the electric

power supply, the other for the eventual

connection of the PR3 or SDP. For

installation refer to the wiring diagram

supplied with the appliance and follow

these simple operations (fig. 01)

1. Open the front hatch by acting on the

1/4 turn closure

.

2. Pass the electric power supply cable

from the fairlead.

3. Connect the earth, the line and then

neutral.

- Before powering the unit electrically

ensure that all protections that

were previously removed have been

replaced correctly.

NOTE:

Check the tightness of all power wire

clamps on commissioning and after

30 days from being put into service.

Successively, check the tightness of all

power clamps every six months.

Loosened clamps can cause overheating

of cables and components.

The units in the VENICE series leave the

factory prepared also to be controlled

from remote panels or by simple switches

(on/off switch, heating/cooling).

If switches are installed for remote

control, the connections to the unit

terminal board must be realised using

cables with suitable section TAB 4.1.1. The

max. distance allowed is 30 m for the

PR3.

ATTENTION

If the remote panel has not been

connected or if it is to be removed

successively, parameters H06 and

H07 must be set at 0 on the board on

the machine (fig.01), otherwise the unit

cannot be piloted by the control on the

same. Refer to the user manual for this

operation.

VENICE (IL) A

SEC. A

(mm

2

)

SEC. B

(mm

2

)

PE

(mm

2

)

015 230V

~

- 50 Hz 13 2.5 0.5 2.5

020 230V

~

- 50 Hz 16 4 0.5 4

025 230V

~

- 50 Hz 20 4 0.5 4

030 230V

~

- 50 Hz 25 6 0.5 6

Tab. 4.1.1

KEY

IL

Master switch

SEC.B

Remote panel power supply

SEC.A

Power supply

PE

Earth

uÛ

uÛ

Power supply

cable

Fairleads

fig. 01

Display

Loading...

Loading...