128 Chapter 7

Post-Repair Procedures

Post-Repair Procedures

Post-Repair Procedures

Table 7-1 Post Repair Procedures lists the required procedures that must be performed

after the replacement of an assembly. These are the recommended minimum procedures to

ensure that the replacement is successfully completed.

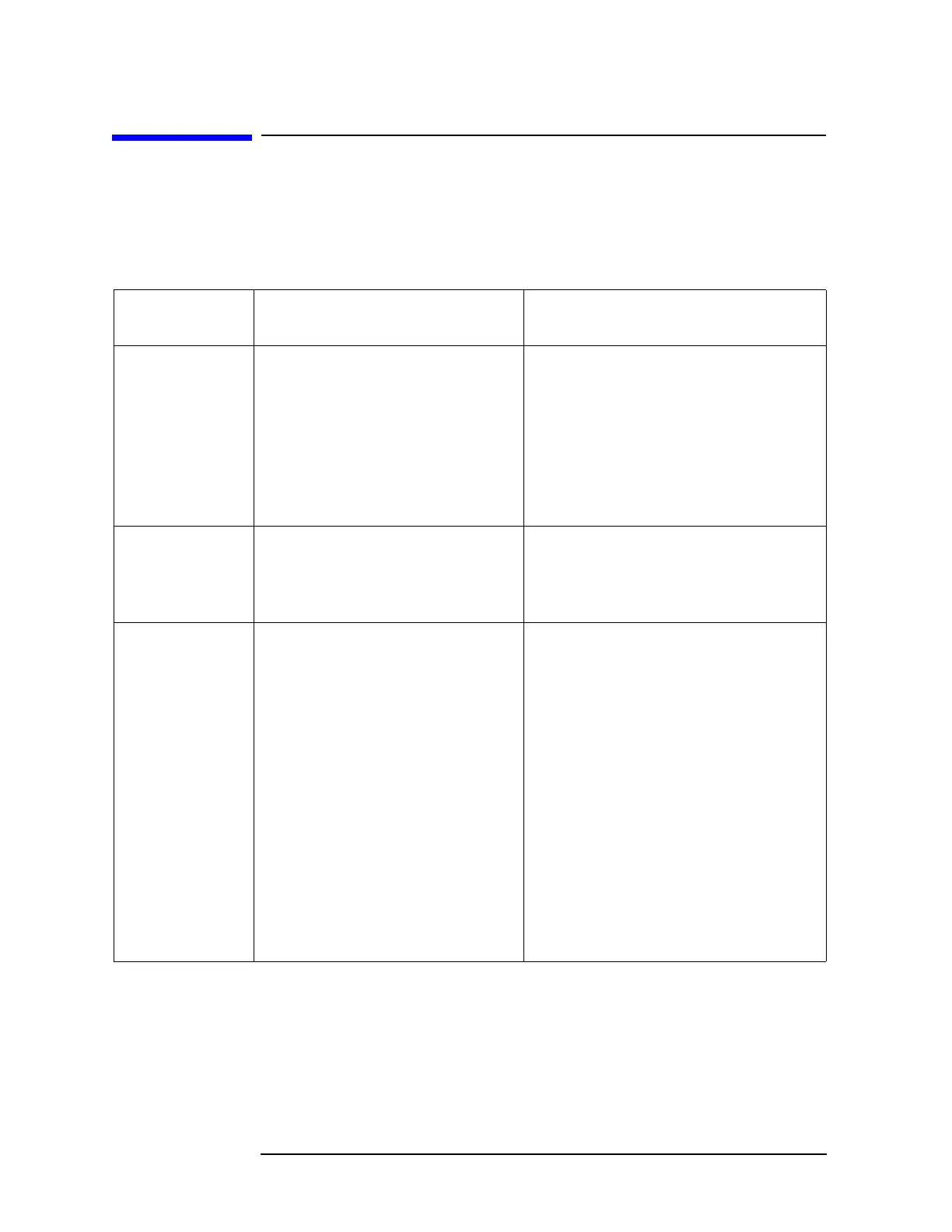

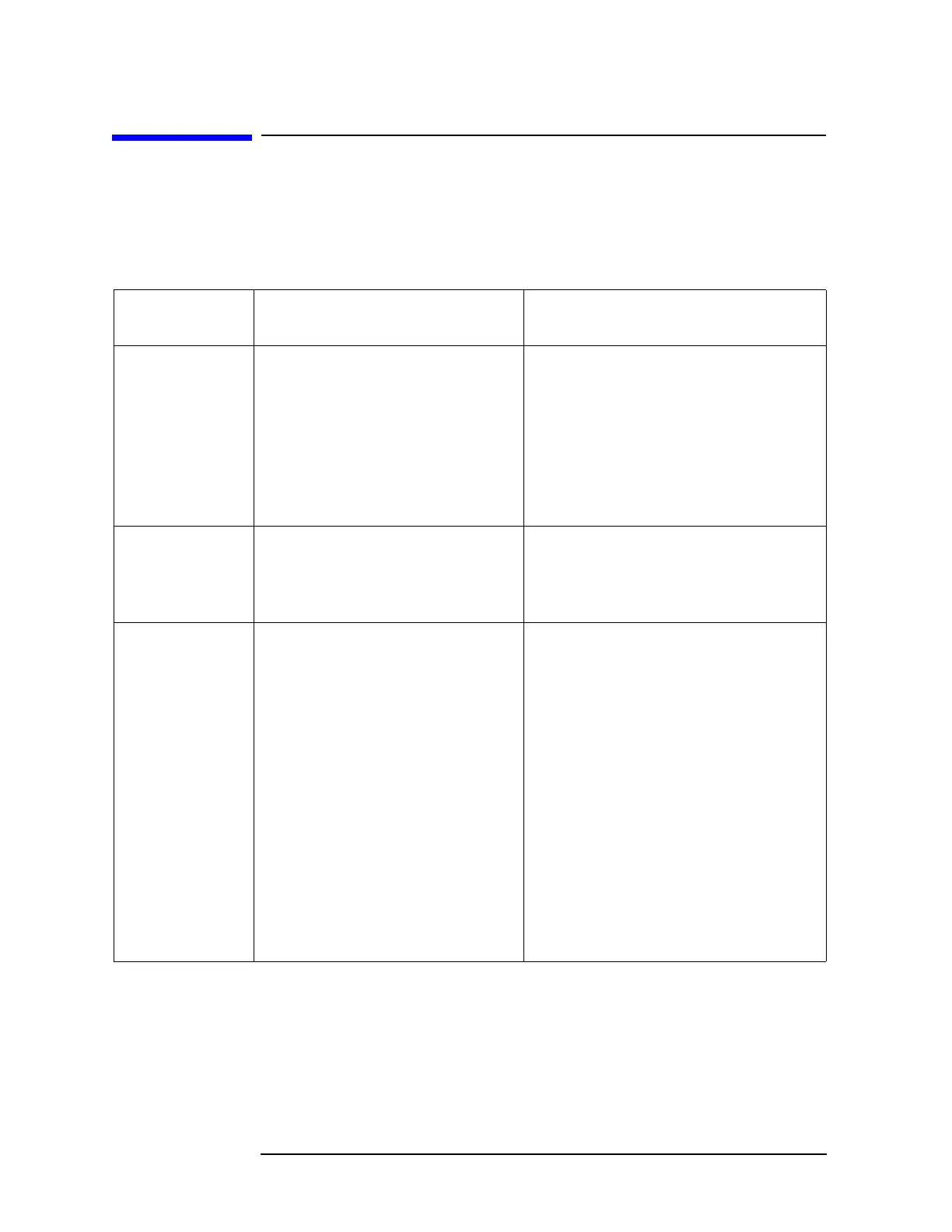

Table 7-1 Post-Repair Procedures

Replaced

Assembly or Part

Required Adjustments

Correction Constants (CC)

Verification

P1001

INSTALLED OS

(E4980-62004)

At first, it is required to install the latest

firmware based on “Appendix B

Firmware Update”.

Perform the following required

adjustments using “PPMC” in Spot

Adjustment of the program.

Power On Test Limit

Inspect the booting process, and power on

test result.

A1 Mother Board Perform the following required

adjustments using “A1 Board” in Spot

Adjustment of the program.

Write ID

Inspect the booting process, and power on

test result.

A2 Analog Board Perform the following required

adjustments using “A2 Board” in Spot

Adjustment of the program.

Write Null phase track default data

Null DC offset Adjustment

Null ADC DC offset Adjustment

ADC Linearity Adjustment

DC Bias Adjustment

DC level V monitor Adjustment (for

opt 001)

DC level I monitor Adjustment (for opt

001)

DC Source Adjustment (for opt 001)

DCR Adjustment (for opt 001)

Impedance Adjustment

AC Level monitor Adjustment

OSC Level Adjustment

Inspect the booting process, and power on

test result.

DC Bias V Level Monitor Accuracy Test (for

opt 001)

DC Bias I Level Monitor Accuracy Test (for opt

001)

AC Signal Level Monitor Accuracy Test

Impedance Measurement Accuracy Test

DCR Measurement Accuracy Test (for opt 001)

Loading...

Loading...