182 Rockwell Automation Publication 750-PM001N-EN-P - February 2017

Chapter 3 Drive Port 0 Parameters

File

Group

No. Display Name

Full Name

Description

Values

Read-Write

Data Type

APPLICATIONS

Pump Off

1187 Pump Off Config

Pump Off Configure

Selects the torque data that will be used for the pump off control.

“Automatic” (0) – Downstroke torque is used if the torque waveform synchronizes with

previously saved waveform. If the position is not found after 6 cycles, the cycle torque is

used. If cycle torque is used, P1191 [Pump Off Status] Bit 3 “Cycle Used” is set to 1

“Enable.”

“Position” (1) – Downstroke torque is used to detect a pump off condition. The torque

waveform needs to be able to synchronize with the previously saved waveform.

“Cycle” (2) – Full pump cycle torque is used to detect a pump off condition.

Default:

Options:

0 = “Automatic”

0 = “Automatic”

1 = “Position”

2 = “Cycle”

RW 32-bit

Integer

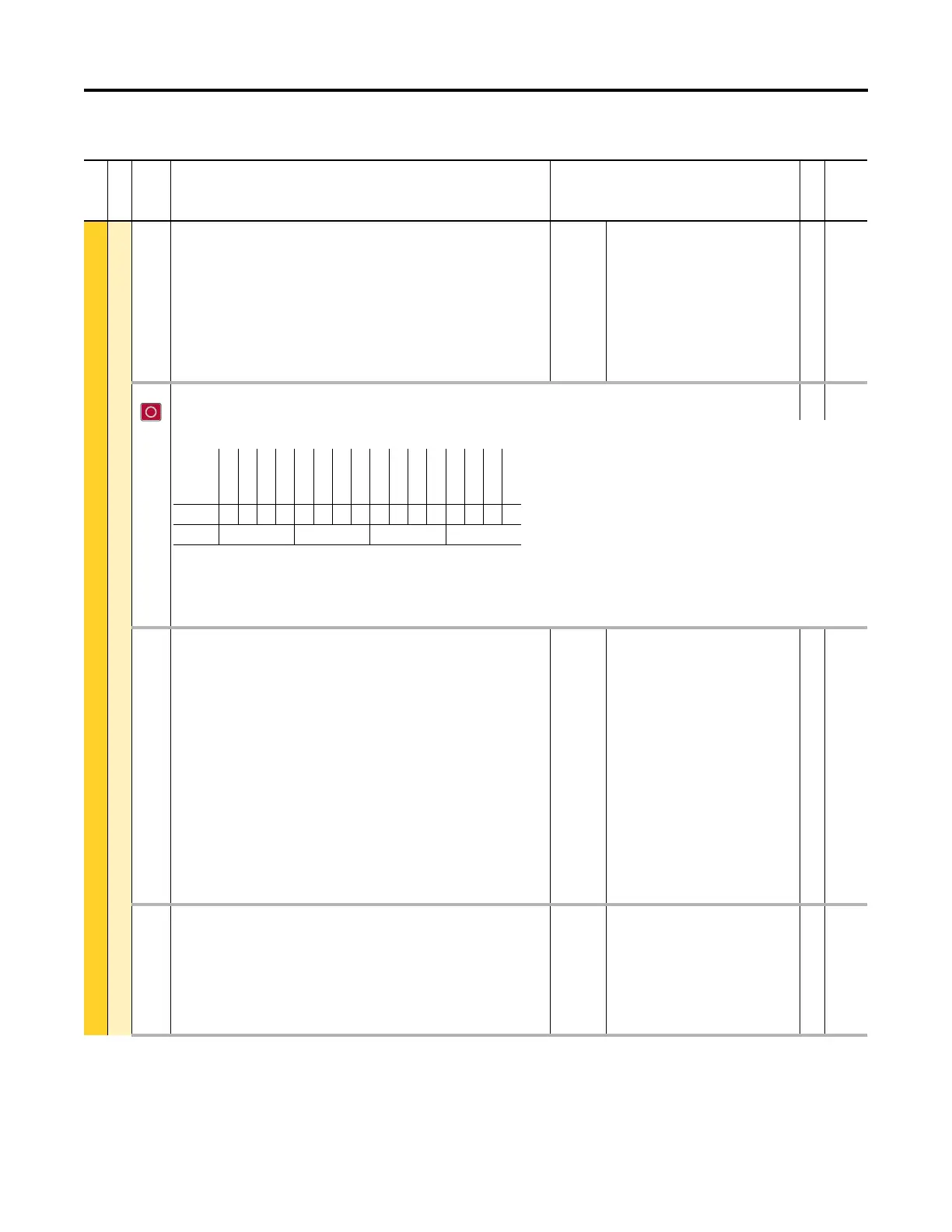

1188 Pump Off Setup

Pump Off Setup

RW 16-bit

Integer

Select pump off options.

Bit 0 “Pos Filter” – Sets level of filtering on torque for position calculation: 0 = Light (Default), 1 = Heavy. Used to remove extra peaks in the waveform.

Bit 1 “Pos Offset” – Enables/disables correction factor for motor slip in position calculator. Set bit if torques and position count are drifting apart.

Bit 2 “Pos Min Trq” – Sets the minimum torque threshold for the position detector. 0 = 10% (Default), 1 = Auto Detect Min Torque.

Bit 3 “Cycle PO Pos” – Enables/disables positive level changes for Pump Off in cycle mode.

1189 Pump Off Action

Pump Off Action

Selects the action to be taken after a pump off condition has been detected.

“Change Speed” (0) – When a pump off condition is detected, speed is reduced by the

percentage set in P1196 [Pump Off Speed] and runs for the time set in P1197 [Pump Off

Time]. If condition continues, speed is reduced a second time. The pump will remain at

this speed until the pump off condition no longer exists.

“Always Stop” (1) – Stops pump when a pump off condition is detected. Pump will

remain stopped for the time set in P355 [Wake Time].

“Stop After 1” (2) – When a pump off condition is detected, speed is reduced by the

percentage set in P1196 [Pump Off Speed] and runs for the time set in P1197 [Pump Off

Time]. Pump will stop if torque continues to change while at the reduced speed. Pump

will remain stopped for the time set in P353 [Sleep Time].

“Stop After 2” (3) – When a pump off condition is detected, speed is reduced by the

percentage set in P1196 [Pump Off Speed] and runs for the time set in P1197 [Pump Off

Time]. If torque change continues, speed is reduced a second time by the same

percentage. Pump will stop if torque continues to change while at the reduced speed.

Pump will remain stopped for the time entered in P353 [Sleep Time].

Default:

Options:

0 = “Change Speed”

0 = “Change Speed”

1 = “Always Stop”

2 = “Stop After 1”

3 = “Stop After 2”

RW 32-bit

Integer

1190 Pump Off Control

Pump Off Control

Enables/Disable the pump off control or select the source for the torque level.

“Baseline Set” (1) – The control uses a torque baseline created after any start of the

drive (first ten cycles). It is critical that this data is gathered from a “full” well.

“Fixed Setpt” (2) – The control uses the value set in P1194 [Torque Setpoint]. Use the

value in P1200 [Pct Drop Torque] as a guideline in “Automatic” or “Position” mode. In

“Cycle” mode use P1198 [Pct Cycle Torque] as a guideline.

Default:

Options:

0 = “Disable”

0 = “Disable”

1 = “Baseline Set”

2 = “Fixed Setpt”

RW 32-bit

Integer

Options

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Cycle PO Pos

Pos Min Trq

Pos Offset

Pos Filter

Default0000000000000000

Bit 1514131211109876543210

0 = Disabled

1 = Enabled

Loading...

Loading...