Rockwell Automation Publication 750-PM001N-EN-P - February 2017 457

Application Notes Appendix C

Torque Prove

Carefully perform the following steps in the order presented.

1. Enter Torque Prove parameter settings.

2. Set speed deviation.

This setting can be lowered once the system has been tuned. The lower this

value, the faster the protection.

3. Set speed deviation level.

This setting can be lowered once the system has been tuned. The lower this

value, the faster the protection.

4. Set brake float tolerance.

Sets the level where the mechanical brake sets in encoderless mode.

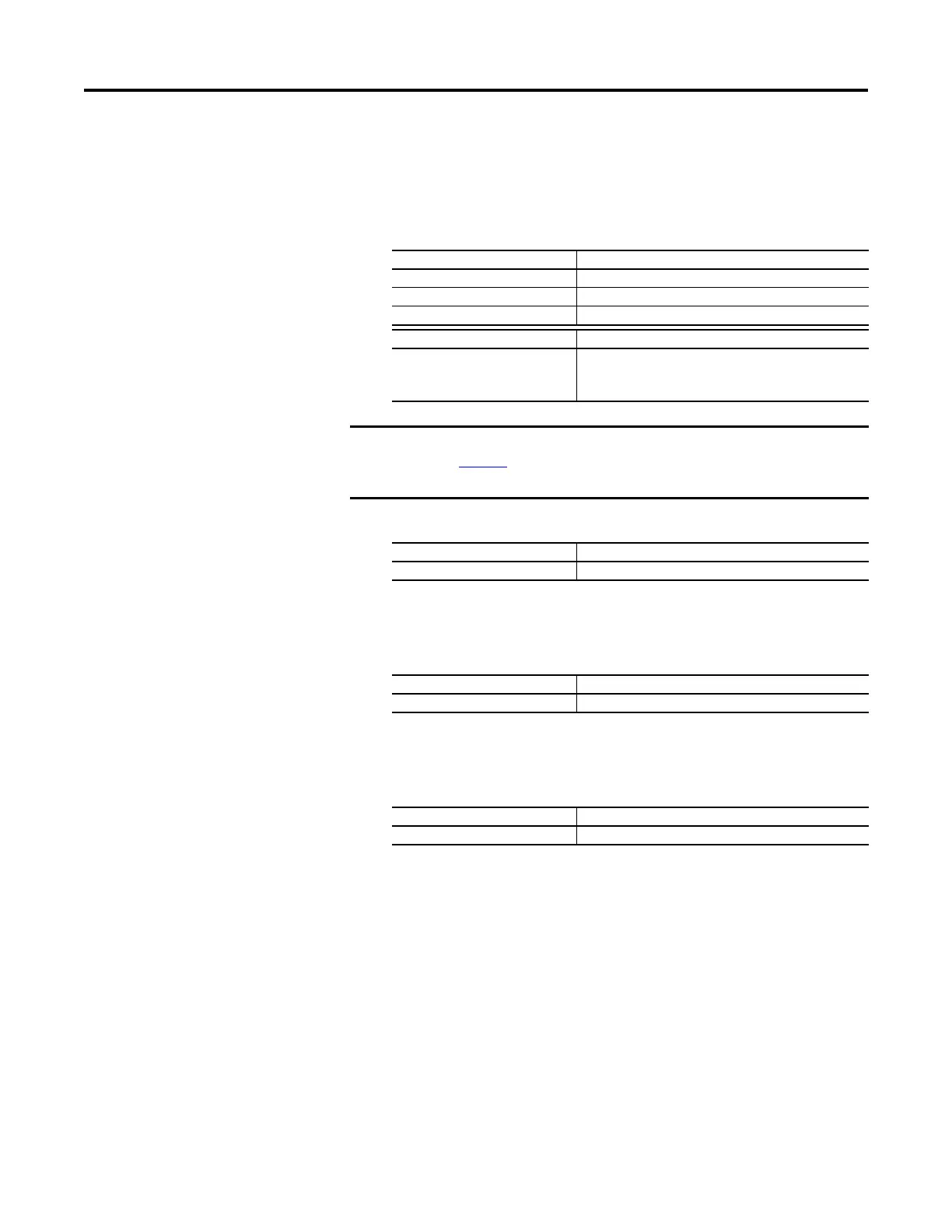

I/O Module Parameter (Port X) Setting

P10 [RO0 Sel] 0.00 (Disabled)

P6 [Dig Out Invert] Bit 0 “Relay Out 0” = 1 (Output Inverted)

P10 [RO0 Sel] Port 0, P1103 [Trq Prove Status], Bit 4 “Brake Set” = 1

Drive Parameter Setting

P1100 [Trq Prove Cfg] Bit 0 “TP Enable” = 1

Bit 1 “Encoderless” = 1

Bit 5 “BrkSlipEncls” = 1

After Torque Prove is activated, the drive is in an alarm state as described on

page 356

. Carefully read the Attention statement and acknowledge it by

setting the required parameter.

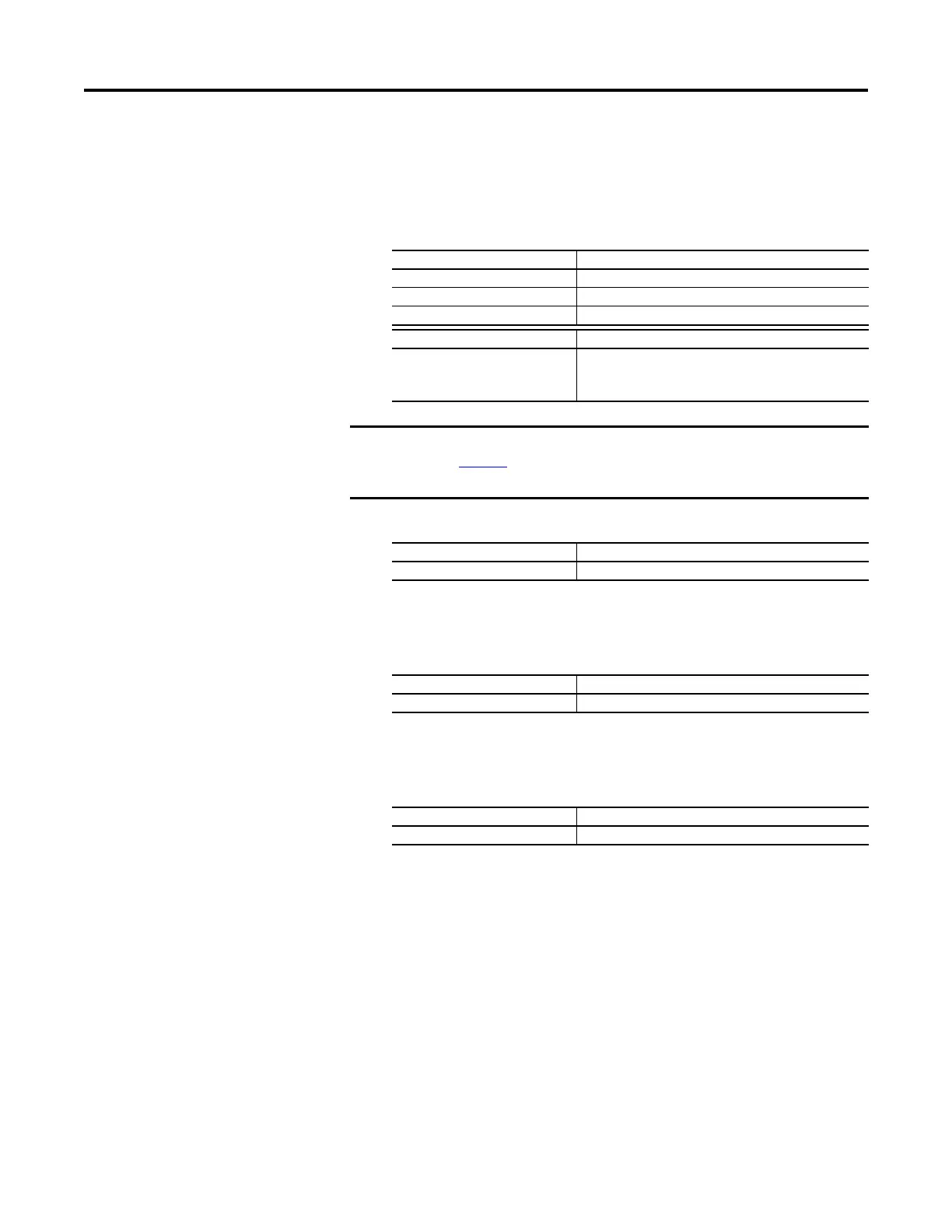

Drive Parameter Setting

P1105 [Speed Dev Band] 10 Hz

Drive Parameter Setting

P1106 [SpdBand Intgrtr] 0.200 Secs (Default)

Drive Parameter Setting

P1111 [Float Tolerance] 2...3 times Slip Frequency of Motor.

Loading...

Loading...