462 Rockwell Automation Publication 750-PM001N-EN-P - February 2017

Appendix C Application Notes

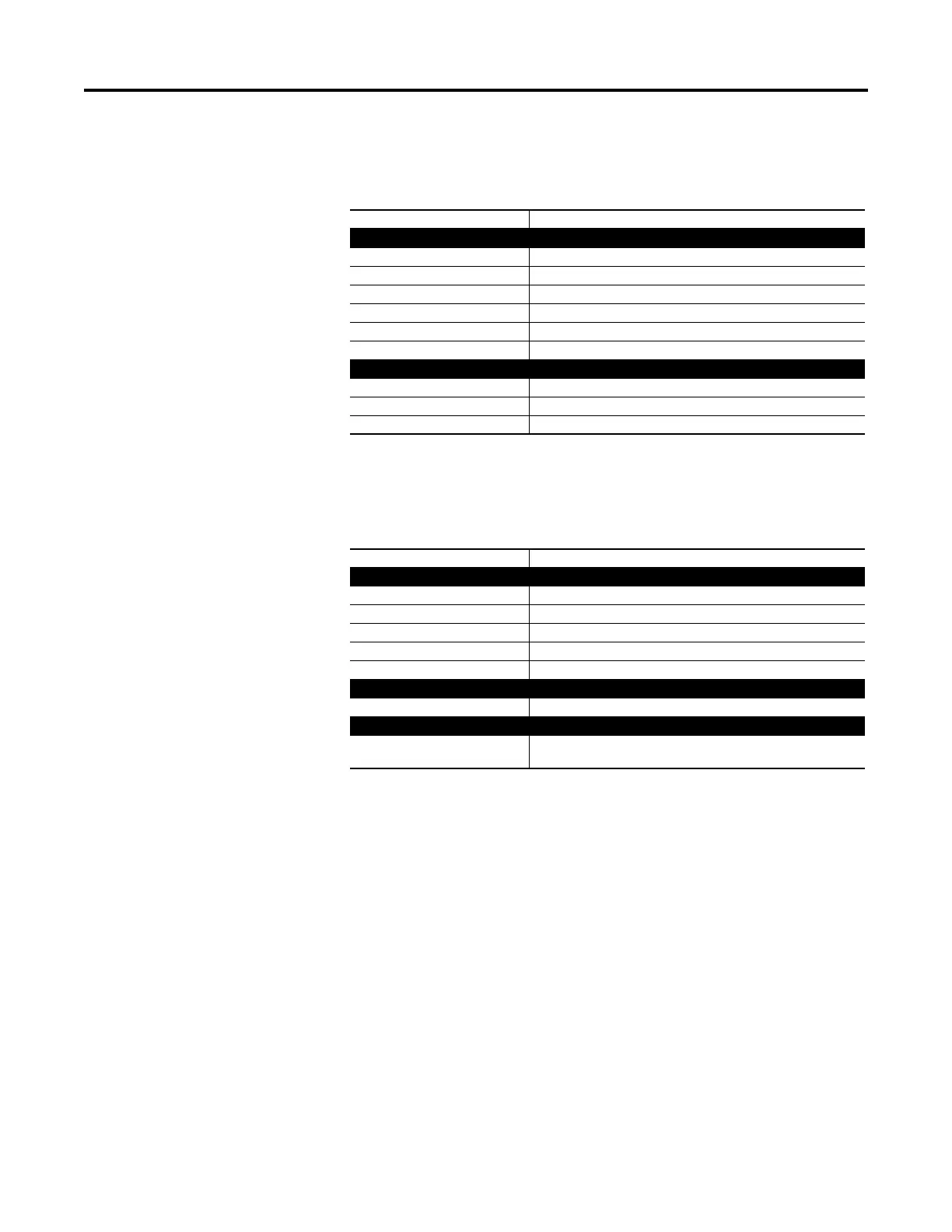

Enter Pump Data

Enter pump data and adjust parameter settings.

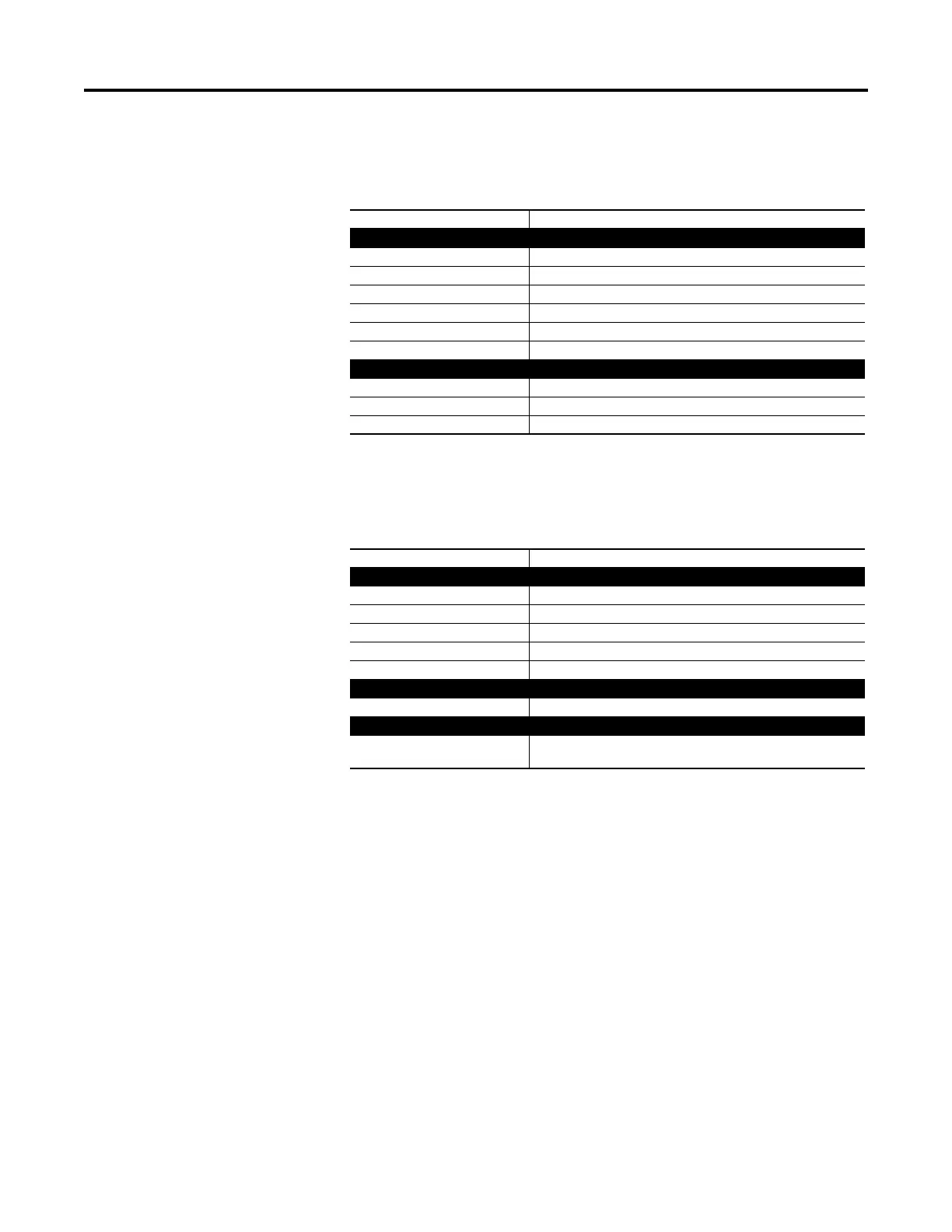

Enter Desired Bus Regulation Data

The following parameter settings assume that a dynamic brake resistor is used.

The following positive and negative torque limits are calculated on powerup and

entered by the drive.

• P670 [Pos Torque Limit] is calculated using the motor parameters.

• P671 [Neg Torque Limit] is calculated using the dynamic-brake resistor

ohmic value and rated torque of the motor. If a dynamic brake resistor is

not used, the default negative torque limit is used.

Change P426 [Regen Power Lmt] to match the value in P671 [Neg Torque

Limit] to maximize dynamic brake performance.

Parameter Setting

Pump Jack

P1178 [Motor Sheave] Diameter in inches.

P1179 [OilWell Pump Cfg] 1 “Pump Jack”

P1181 [Gearbox Limit] Percent of P1182 [Gearbox Rating]

P1182 [Gearbox Rating] Nameplate gearbox rating.

P1183 [Gearbox Ratio] Nameplate gear ratio.

P1184 [Gearbox Sheave] Diameter in inches.

Pump Off

P1187 [Pump Off Config] 0 “Automatic” (Default)

P1189 [Pump Off Action] Select preferred action.

P1190 [Pump Off Control] 0 “Disable” (Default)

Parameter Setting

Brake Features

P372 [Bus Reg Mode A] 2 “Dyn Brake”

(1)

(1) If no dynamic braking resistor is used, set P372 [Bus Reg Mode A] to 1 “Adjust Freq” (Default).

Speed is sacrificed for bus regulation and P524 [Overspeed Limit] must be adjusted.

P382 [DB Resistor Type] 1 “External”

P383 [DB Ext Ohms] Based on performance preference.

P384 [DB Ext Watts] Based on performance preference.

P385 [DB ExtPulseWatts] Based on performance preference.

Motor Overload

P409 [Dec Inhibit Actn] 0 “Ignore”

Load Limits

P426 [Regen Power Lmt] Set to match the value that is calculated for P671 [Neg Torque Limit], see

below this table.

Loading...

Loading...