7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

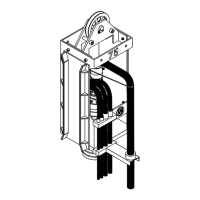

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

IV. PREPARATION AND OPERATION

IV-1. Rigging of Vibratory Hammer

A steel wire rope sling must be connected to the lifting bail located on top of the vibro. The required

strength of this sling depends on the capacity of the crane and the work to be carried out. A safety

factor of six is recommended. Several turns of a smaller diameter cable will result in a longer lasting

sling than one larger diameter cable. When making a sling, avoid using cheap cable clamps. Check

the clamps daily.

IV-2. Installing the Clamp Attachment

The Vibro is fitted with a standard sheet clamp at the factory. However, several types of clamps are

used on APE vibros to fit many different types of piles. A step by step procedure is provided as follows:

1.) Clean all drilled and tapped threads on the bottom surface of the gearbox. Use a 1 1/2"UNC

tap to clean any rusted threads and blow out any remaining fragments with compressed air. If

there is a cutting torch on the jobsite then use the oxygen setting to blast the threads clean. Hold

a rag over the tapped hole to prevent flying dirt from blasting into your eyes.

2.) Clean the machined bottom surface of the gearbox and prepare to mount the clamp. If the

clamp bolts should ever break, check the machined surface with a straight edge to make sure

it is true and flat.

3.) Clean the machined surface of clamp. Eye-ball the entire surface for damage. Make sure the

surface is flat and void of all dirt.

4.) Start by getting the center bolt in first and work outwards. Do not tighten bolts until you have

all of the bolts started.

5.) Torque bolts to the bolt specifications.

6.) Go around all bolts at least three times making sure they are tight.

7.) After vibrating the first pile, check the bolts again.

8.) If one bolt breaks, replace them all since they may be weak or cracked.

9.) Never operate the vibro with missing clamp bolts.

WARNING: Do not use grade five bolts. All bolts should be allen head cap screw bolts. If one bolt

breaks then the others are damaged and must be replaced. Never drive piles if one bolt is broken.

Bolts break only because they were not tight and the crew neglected to check them. A good operator

insists that every bolt is checked twice daily.

Page 4-1

Loading...

Loading...