7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

IV. PREPARATION AND OPERATION (Continued...)

IV-4.

Filling Vibrator Pressure Hose

The vibrator is shipped with the hoses filled with oil. However, if the unit has been sitting for a long

period of time or if a damaged hose has been replaced with a new one, then the hoses must be filled.

Hook up all the hoses to the power unit (see Section IV-3 on [page 4-2] and Figure 4-A.). Start the

power unit and let it run for ten minutes before running the vibro. The hoses will fill up by themselves

in ten minutes even if the vibro is not in the vibrate mode.

IV-5. Bleeding the Clamp Attachment Hydraulic Hoses

If the opening and closing of the jaws seems spongy or slow, it may be a result of air in the clamp

hoses. Normally there is no need to worry about bleeding the clamp lines because the unit is shipped

fully tested. However, should the vibro sit for a long period of time, if a new attachment is being

installed or if a damaged clamp hose has been replaced, then the system may require bleeding to

remove unwanted air in the system. To bleed the clamp system, follow these steps:

1.) Shut Power Unit OFF.

2.) Make sure the clamp line quick dis-connects are coupled to the power unit.

3.) Start the power unit engine and run at 1500 rpm. Give the engine time to warm up.

4.) Loosen the clamp lines at the hydraulic cylinder by backing the fittings off just a little.

5.) Turn the clamp switch on the power unit control pendant to "CLOSE" and wait for oil to flow

from the fittings. WATCH FOR AIR BUBBLES. When air bubbles have stopped then quickly

re-tighten the fittings.

6.) Repeat the same procedure for "OPEN" side.

7.) Operate the jaws. If they are still a bit spongy then repeat bleeding steps once more.

WARNING: DO NOT BLEED SYSTEM AT FULL ENGINE THROTTLE BECAUSE

TOO MUCH OIL WILL FLOW FROM THE HOSES AND COULD CAUSE INJURY.

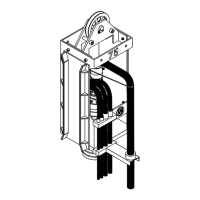

Figure 4-B. Bleeding Clamp Attachment

Bleed system by cracking fittings on

the clamp cylinder and allowing air

to escape.

Clamp "Open"

Clamp "Close"

Clamp Cylinder

Page 4-3

Loading...

Loading...