7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123

1

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

3

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123

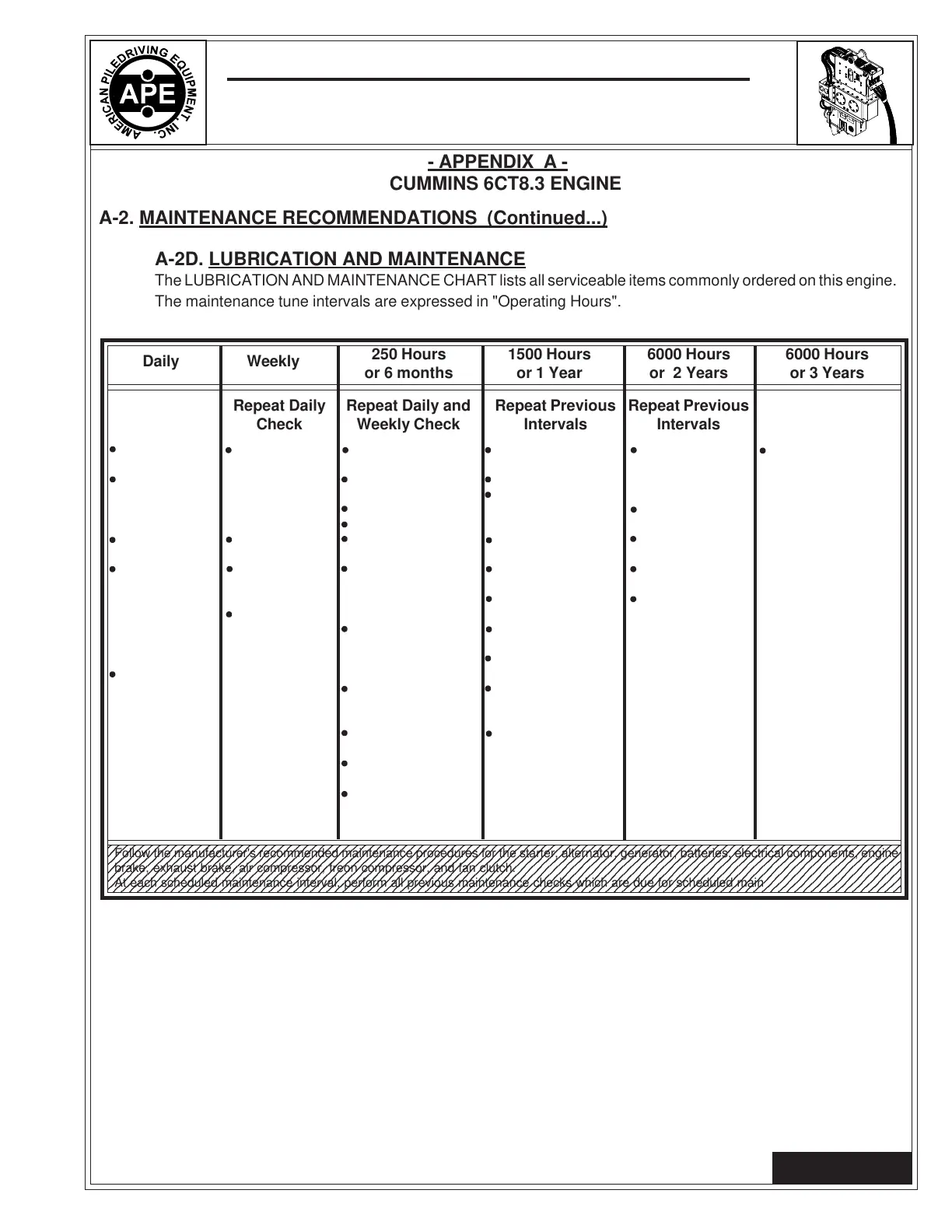

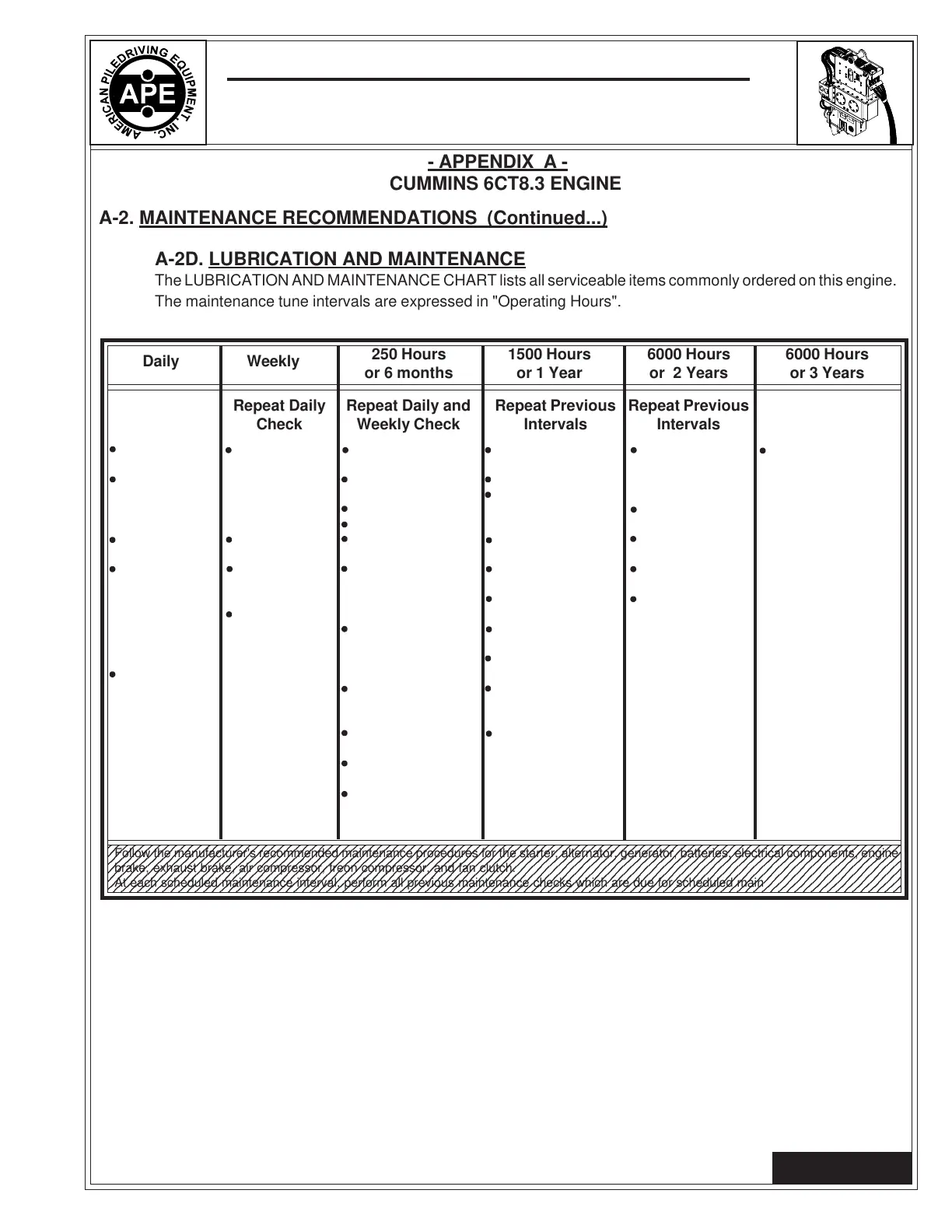

A-2D. LUBRICATION AND MAINTENANCE

The LUBRICATION AND MAINTENANCE CHART lists all serviceable items commonly ordered on this engine.

The maintenance tune intervals are expressed in "Operating Hours".

- APPENDIX A -

CUMMINS 6CT8.3 ENGINE

A-2. MAINTENANCE RECOMMENDATIONS (Continued...)

Daily

1500 Hours

or 1 Year

250 Hours

or 6 months

6000 Hours

or 3 Years

6000 Hours

or 2 Years

Weekly

Repeat Daily

Check

Repeat Daily and

Weekly Check

Repeat Previous

Intervals

Repeat Previous

Intervals

Follow the manufacturer's recommended maintenance procedures for the starter, alternator, generator, batteries, electrical components, engine

brake, exhaust brake, air compressor, freon compressor, and fan clutch.

At each scheduled maintenance interval, perform all previous maintenance checks which are due for scheduled maintenance.

Check operator's

report

Check and bring

to correct level

- Engine Oil

- Coolant

Visually inspect

fan.

Visually inspect

engine for

damage, leaks,

loose or frayed

belts and correct

or record for

future action.

Drain fuel-water

separator.

Check air intake

system for wear

points or damage

to piping, loose

clamps, and

leaks.

Check air cleaner

restriction.

Check and clean

air cleaner

element.

Drain moisture

from air tanks.

Adjust valves and

injectors.

Steam clean engine.

Check torque on

turbocharger mounting

nuts.

Check torque on

engine mounting bolts.

Replace hoses as

required.

Check/Adjust engine

valve lash.

Check/Adjust low idle

speed.

Test/Exchange fuel

injection nozzles.

Inspect coolant pump.

Clean cooling system.

(Internal)

Inspect/Rebuild

Alternator.

Clean cooling

system and change

coolant and

antifreeze.

Inspect temperature

regulator.

Inspect/Rebuild

turbocharger.

Inspect/Rebuild

starter.

Check and adjust

clutch.

Clean and calibrate

the following:

(Rebuild or exchange

if required.)

- Injectors.

- Fuel pump.

- Air compressor.

- Fan clutch.

- Water pump.

- Fan hub.

- Fan idler pulley

assembly.

- Vibration damper.

Change Lubricating

Oil.

Change Lubricating

Oil Filters.

Change Fuel Filter.

Change Coolant Filter.

Clean Crankcase

Breather.

Check engine coolant

concentration level.

Add make-up if

required.

Replace final Fuel

Filter/Clean primary

Fuel Filter. Drain

water from fuel tank.

Inspect/Replace

Alternator, Fan and

Accessory Drive

Belts.

Inspect/Replace

Hoses and Clamps.

Lubricate Fan Drive

Bearings.

Clean/Check Battery

electrolyte level.

Repeat Previous

Intervals Which

Are Due

Page A-12

Loading...

Loading...