7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

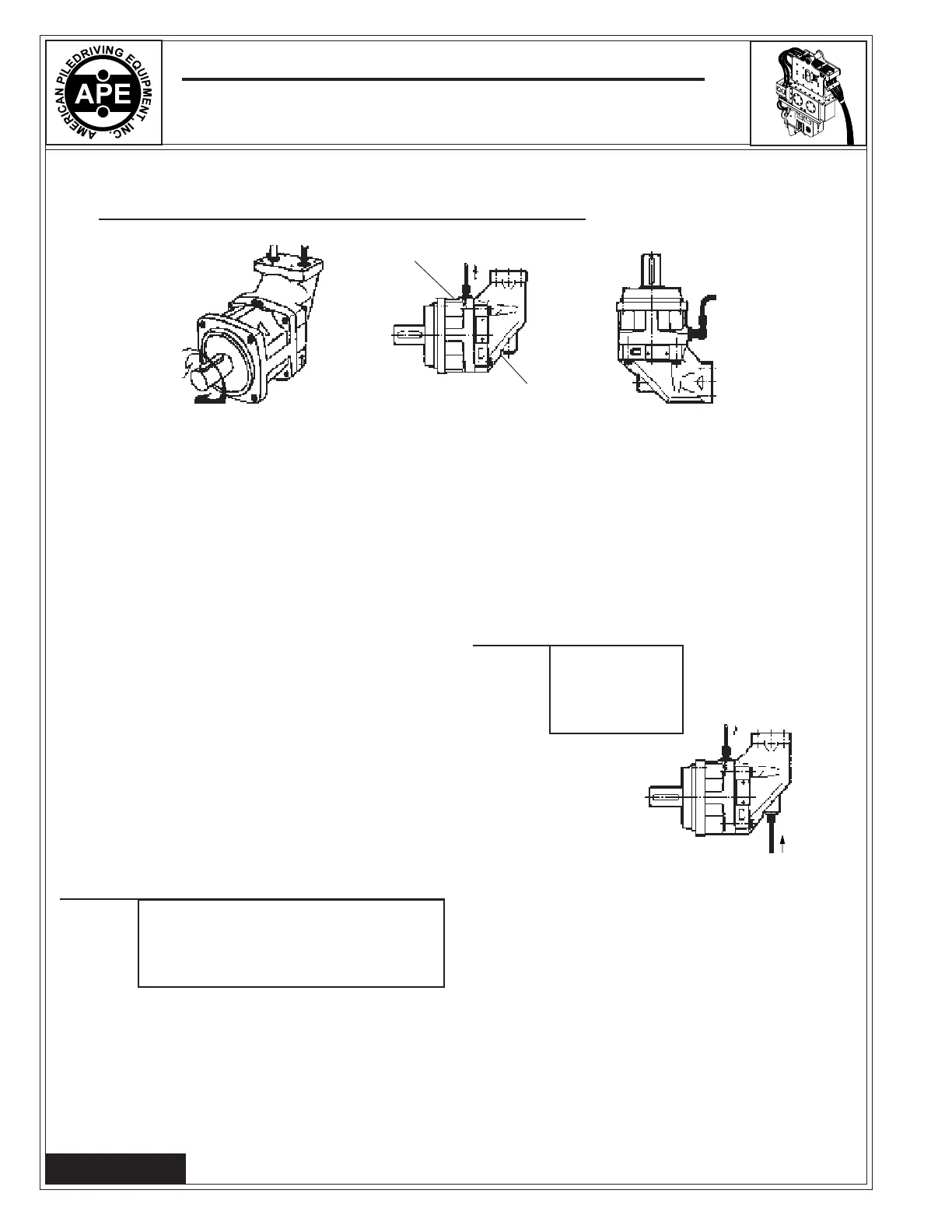

DIRECTION OF ROTATION

The F12 motor is bi-directional. The picture shows direction of flow vs.

shaft rotation. When fluid enters port PB (black arrow) the motor turns

counter clockwise, and when port PA is pressurized (open arrow) the

shaft turns counter clockwise.

The F12 pump rotates clockwise or counter clockwise. The ordering

code shows the direction of rotation.

FILTRATION

To obtain maximum motor service life, the fluid cleanliness should be

checked to meet ISO code 18/13 or better (ISO 4406). A10 um

(absolute) filter is recommended.

REQUIRED INLET PRESSURE

The motor sometimes operates as a pump (e.g. when it is used in a

propel transmission and the vehicle is going downhill). The motor inlet

port must then be supplied with sufficient fluid pressure, or increased

noise and deteriorating performance may otherwise be experienced.

CASE PRESSURE

The table shows the highest recommended case pressure (F12 shaft

seal type H) as a function of shaft speed.To obtain the longest seal

life, the case pressure should be limited to 50% or less of the figures

shown.

NOTE: Contact VOAC Hydraulics for information on other shaft

seals.

Motor case pressure [bar] vs. shaft speed [rpm]

designation 1500 3000 4000 5000 6000

F12-30 14.0 7.0 5.5 4.5 3.5

F12-40 12.0 6.0 4.5 3.5

F12-60 12.0 6.0 4.5 3.5

F12-80 10.0 5.0 4.0

F12-110

CASE DRAIN CONNECTIONS

There are two drain ports (PC and PD). The uppermost drain port

should be utilized. In mounting positions such as 'shaft up', a drain

line loop can be formed to provide bearing lubrication and cooling.

Preferably, the drain line should be connected directly to the tank to

avoid excessively high case pressure.

NOTE: When the motor is operating, the case must be filled with fluid

to at least 50%.

V. MAINTENANCE (Continued...)

V-8.

Hydraulic Motor - Installation and Start-Up. - Figure 5A.

Drain port PD

Drain port PC

Main port PA Main port PB

Clockwise rotation

Counter-

clockwise

rotation

OPERATING TEMPERATURE

The following temperatures should not exceed (type H seal):

System fluid: 80deg. C

Drain fluid: 100deg. C

Type V ('Viton') shaft seals can be used to 115deg. C.

Continuous operation may require case flushing in order to meet the

above viscosity and temperature limitations. The table shows operating

speeds, above which flushing is usually required, as well as suggested

flow through the case.

Motor Speed Flow

designation [rpm] [I/min]

F12-30 3500 4-8

F12-40 3000 5-10

F12-60 3000 7-14

F12-80 2500 8-16

F12-110 2300 9-18

BEFORE START-UP

Make sure the motor case as well as the entire hydraulic system is filled

with a recommended fluid. The internal leakage, especially at low

operating pressures, is not sufficient to provide lubrication at start-up.

HYDRAULIC FLUIDS

Ratings and performance data for series F12 are based on operating

with good quality, contamination-free petroleum-based fluids, Hydraulic

fluids type HLP (DIN 51524), automatic transmission fluids type A, or

API CD engine oils can be used.

At operating temperature, the viscosity (of the drain fluid) should

normally be kept above 8 mm2/s (cSt). At start-up, the viscosity should

not exceed 1000 mm2/s.

Fire resistant fluids, when used under modified operating conditions,

and synthetic fluids are also suitable. Contact VOAC Hydraulics for

further information.

Drain

Flushing

Page 5-6

Loading...

Loading...