7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

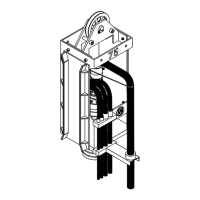

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

3. Clamp "OPEN/OFF/CLOSE" Switch

The CLAMP OPEN/OFF/CLOSE SWITCH is used to control the direction of the hydraulic flow

coming from the clamp pump. When the engine is running and the switch is in the "OFF"

position, all clamp PUMP oil is returned to the tank. Turning the CLAMP CLOSE/OFF/OPEN

SWITCH to the close position energizes the clamp close solenoid, which can be observed

with the lighted connector. When the close solenoid energizes, the clamp close valve closes

sending hydraulic oil to the closed side of the clamp cylinder. When the pressure reaches

3300 psi, the CLAMP PRESSURE SWITCH (located on the clamp manifold) opens, de-

energizing the closed solenoid and lighting a lamp in the CLAMP OPEN / OFF / CLOSE

SWITCH and the green lamp on the remote HAND HELD PENDANT. If the pressure drops

below 3000 psi, the CLAMP PRESSURE SWITCH closes allowing the close solenoid to

recharge the clamp close hydraulic circuit. Note: If the light on the solenoid stays on and the

green light on the pendant fails to come on then the pressure switch may be faulty. Do not

operate the machine if you can see the clamp closed solenoid light on all the time. (Note: the

clamp closed solenoid light is located on the solenoid.) It should go off as soon as the jaws

close and the pressure rises above 3300 psi. When jaws are closed properly, the green light

will glow on the remote pendant, or if operating from the panel, the green light is built into the

switch.When the diesel engine is running, Turning the clamp switch to "OPEN" energizes the

open solenoid and directs oil to the open side of the clamp cylinder and the jaws open.

4. Drive "FORWARD/REVERSE" Switch

The DRIVE FORWARD/REVERSE SWITCH is used to control the hydraulic motors on the

vibrator or for supplying forward and reverse direction on a drill. With the engine running and

the DRIVE FORWARD / REVERSE SWITCH in the forward position, the forward drive

solenoid energizes, which can be observed with the lighted connector. With the forward drive

solenoid energized, the forward valve opens, sending hydraulic fluid to the hydraulic motors,

and the motors rotate. With the engine running and DRIVE FORWARD/REVERSE SWITCH

in the reverse position, the reverse drive solenoid energizes, which can be observed with the

lighted connector. With the reverse drive solenoid energized, the reverse valve sends oil to

the vibrator motors but the motors do not rotate because all oil flow is directed around the

motors via the ANTI-CAVITATION CHECK VALVE located on the vibro suppressor housing

and plumbed into the hoses leading to and from the hydraulic motors. Therefore, the vibrator

runs in the forward direction only, and this direction is used for driving or pulling all piles. The

reverse direction is used when the power unit is supplying oil to a drill or other attachment or

when flushing the oil during initial startup.

5. "SYSTEM OK" Light

The "SYSTEM OK" Light is lighted when the engine is running and all systems are normal.

6. "SPARE" Light

VII. MODEL 260 POWER UNIT (Continued...)

VII-2B.

Controls: (Understanding How They Work) (Continued...)

Page 7-5

Loading...

Loading...