7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

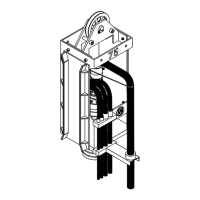

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

A-1D. Determining Cause Of Shutdown (Continued...)

High Water Temperature Checks - Engine Running

1. Determine if the load was too great for the engine - Reduce the load and allow the engine

to cool while running.

2. If pressure steam or water leaks are visible, remove the load and stop the engine.

Have necessary repairs made.

3. Check for collapsing or deteriorated water hoses. Have repairs made.

4. Check for noisy water pump operation. Have necessary repairs made.

5. Refill the cooling system with a solution of water and permanent-type antifreeze if below

freezing temperatures are expected; or with a solution of approved water and Corrosion

Inhibitor. Follow the instructions on the container.

WARNING: DO NOT remove the pressure cap on an overheated engine. The coolant is

under pressure and relieving the pressure will cause the coolant to flash into steam.

NOTE: If there is adequate coolant in the cooling system, gradual cooling is preferred by running the

engine at half speed. This eliminates hot spots in the engine, and possible failure.

High Water Temperature Checks-Engine Stopped and Cold

1. Check coolant level. Determine if the coolant has proper antifreeze protection. A

50-50 solution of permanent-type antifreeze and approved water will give protection

below -200F (-290C).

2. Check to be sure the raw water valve has been opened.

3. Check engine room vents and/or louvers. Be sure the engine is receiving sufficient air.

4. Be sure temperature regulators are operating at proper temperature range.

5. Inspect all water hoses carefully for collapsing, external and internal failures. Replace

hoses as required.

6. Have the cooling system cleaned.

CAUTION: If severe or prolonged overheating has occurred, contact your engine dealer to

have your engine checked for possible damage.

- APPENDIX A -

CUMMINS 6CT8.3 ENGINE

Page A-8

Loading...

Loading...