28 Ultrasound Controller Manual

Connecting the level sensor

The Level Sensor cable may not be

extended. Maximum cable length, see

Level Switch manual. The unshielded

part of the cable should be no longer

than 40mm. The shield shall if possible

be connected to ground via shielded

cable glands. To minimize the risk of

electric interference and noise,

especially in ex-installation, see Electric

Noise page 10.

If D72 is mounted inside a metal

cabinet it is good to connect D72 to the

cabinet (ground) using grounded cable

glands for the Level Switch cables. If

grounded cable glands are not used

then terminal 16 on the D72, DP72,

GS72 or terminal 19 on D128 can be

connected to the cabinet instead.

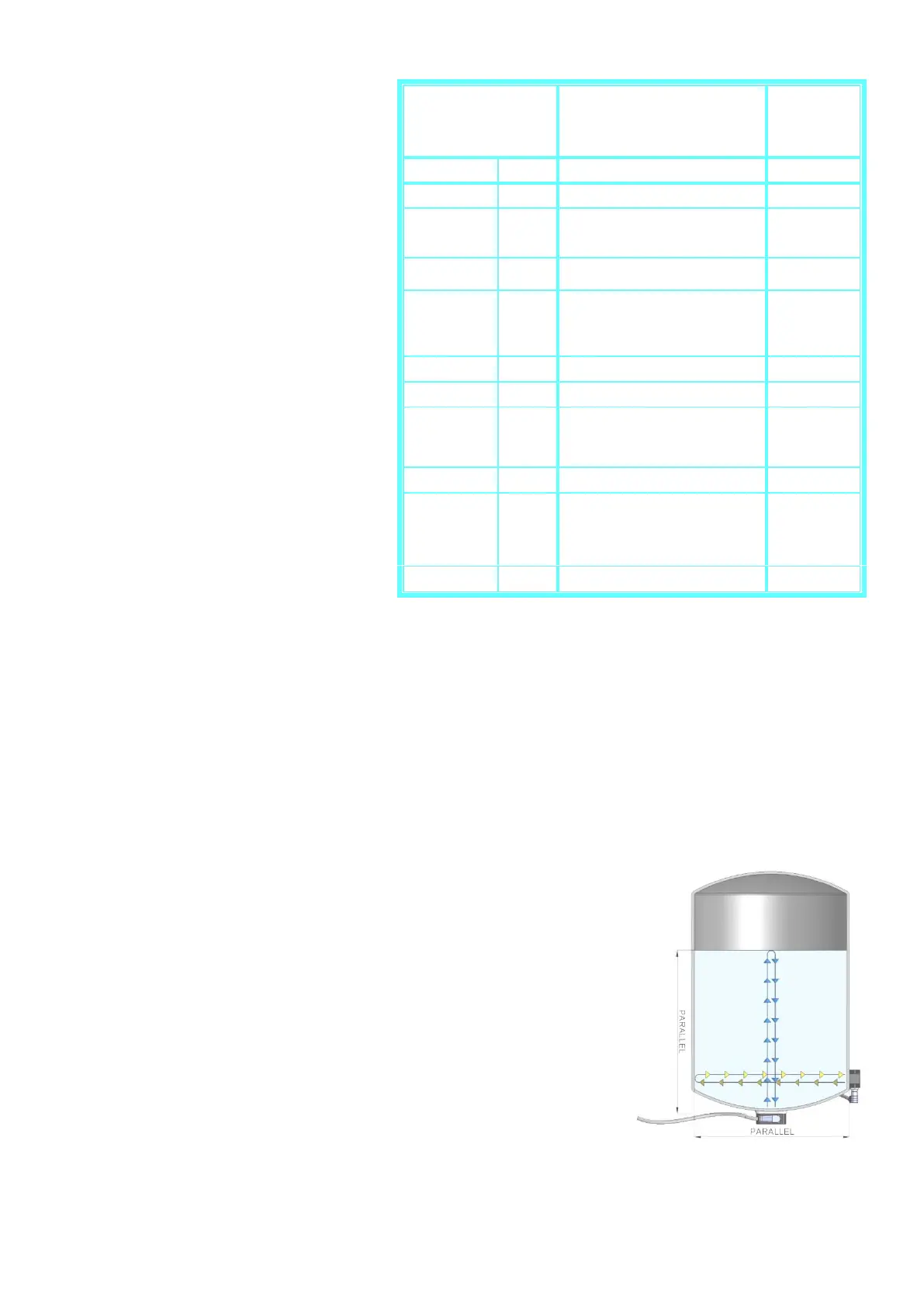

Mounting the Sensor for level

and the velocity sensor

Level Sensor 1 or Level Sensor 3

measures the level and it is a Level

Switch type of sensor which is mounted under the bottom of the container. The ultrasound travels

through the bottom and it is important the sound can pass easily through the bottom into the

liquid. It depends on the wall material and thickness. Steel or glass bottom 1,2mm - 7 mm are ok.

Most plastics let sound trough well except polypropylene and fiber reinforced plastics. For

stainless steel, best result is achieved with bottom thickness being a multiple of 1,42mm

(resonance at 2MHz half wavelength). Stainless steel bottom thickness 7mm 5,7mm 4,3mm

2,8mm or 1,4mm is ok at 2MHz which is the best frequency for the Level Switch. For other

thicknesses other less ideal frequencies will be chosen by the Ultrasound Controller. The

thickness of the bottom also determines how well low levels can be measured. When the bottom

is thick, vibrations within the wall decays slowly and measurements of low levels becomes more

difficult. Minimum level that can be measured depends on the bottom thickness and material.

The ultrasound beam is narrow (beam angle is about 10˚) so the level sensor must be aimed in

such a way that the echo from the surface is properly returned back

to the level sensor. If the bottom is not horizontal, silicone sealant

can be used to glue the Level Switch at an angle, see below. See

Level Switch manual how to glue the sensor. The GF90 contain

both level and velocity sensors. Sound velocity varies with liquid

and temperatures. The Level Switch used as a sensor for velocity

is placed low on the container wall. It measures and compensates

for sound velocity changes. It also makes level switch

measurement which can be used to limit the measured level for

extra reliability.

Mounting the velocity sensor

Velocity Sensor 2 and Velocity Sensor 4 is a Level Switch-type of

sensor which is used to measure the sound velocity of the liquid. It should be mounted on the

container wall to measure the echo from the opposite container wall. If possible near the bottom

Loading...

Loading...