27

6.4.5 Outer Axle Bearing Lubrication

DO NOT USE HIGH PRESSURE

PNEUMATIC GREASING EQUIPMENT

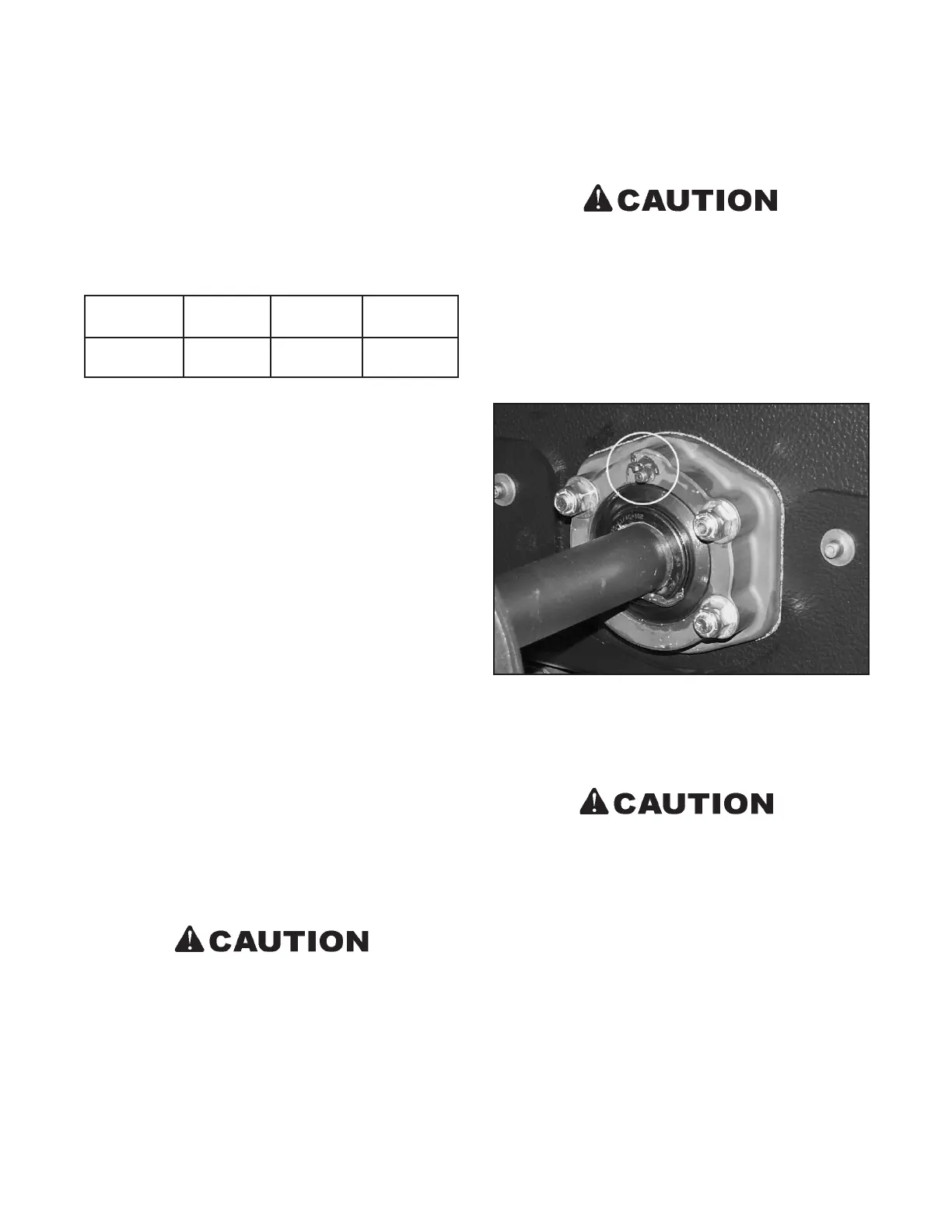

Eachouteraxleangeisequippedwithonegreasenipple.This

grease nipple supplies grease directly to the outer axle bearing.

It requires re-greasing every 25 hours of operation or before

the vehicle is taken out of service for any extended period. Use

a pistol grip type grease gun to avoid dislocating the bearing

seals due to excessive grease pressure. Figure 6-10.

Figure 6-10. Outer bearing ange.

To promote regular maintenance of important Argo compo-

nents, ARGO has provided an access hole through each rim

and hub for ease of bearing lubrication.

Do not use high pressure or excessive amounts of grease.

Damage to the bearing seals could result.

6.4.6 Idler Shaft Outer Bearing Lubrication

Leftandrighthandsideouteridlershaftbearingsaretted

withagreasetting.With therewall andfront oorpan

removed,thesegreasettingareaccessibleatthetopofthe

bearingange.Allofthesecanbeaccessedconvenientlywith

agreasegun ttedwith aexible extensionhead. (Figure

6-11) Grease with a small amount of a lithium based, NLGI

#2 or 3 mineral oil based grease, (such as Shell Alvania #3

or ARGO Brand Multi-Purpose Grease Part No. 130-105).

Apply every 50 hours of operation, if vehicle has been used

in water for extended periods of time or whenever major

maintenance is performed on the vehicle.

SECTION 6

OIL, FILTER AND LUBRICATION INFORMATION

Recommended Oil:

ARGO Brand Chain Lube Auto Oil - 1L (part no. 130-100)

or any good quality oil of the proper viscosity (based on

temperature, see chart) can be used. The oil must be able to

penetrateintothebushingsandsideplatestobeeective.Do

not use used oils, high tack oils (i.e. chainsaw bar oil), heavy

oil, or grease.

TEMPERATURE

-40 ~ 0 C

(-40 ~ 32 deg. F)

0 ~ 40 C

(32 ~ 104 deg. F)

40 ~ 50 C

(104 ~ 122 deg. F)

OIL VISCOSITY SAE 10

or 5W-30

SAE 20

or 10W-30

SAE 30

or 10W-40

First time operation:

1. Fill the reservoir with appropriate oil.

2. Removethefrontoorpan,rewall,andrearoorpan.

3. Turn the key to run position, press and hold the override

switch. You will hear the pump.

4. With the pump running watch below the drip tubes to see

when the oil begins to drip. It may take close to 2 minutes

of continuously holding the switch before the system is

primed. The oil will start dripping on the front chains

several seconds before it drips on the rear.

5. Once the oil starts dripping watch the drips to make sure

they are falling onto the side plates of the chain.

6. Loosen the bolt holding the drip tube and adjust the posi-

tion as required.

System may require priming if reservoir is run dry or after

extended periods of non use.

Maintenance:

• Check the level in the reservoir prior to daily operation.

• For optimum pump and chain life, do not let the reservoir

run dry.

• Periodically check to make sure all holes are dripping

oil correctly.

• Wiping the bottom of the drip tubes with a rag will remove

any larger deposits of dirt.

• A full reservoir of oil should last approx. 40 hrs. of run

time.

If your vehicle is equipped with an auto chain lube

system, monitor steering brake discs and service brake

discs weekly, for any signs of oil contaminated dirt and

debris. This can be the result of excess oil spraying from

moving chains. Regularly clean or pressure wash drive

train if oily dirt and debris builds up on drive chains,

brake discs or other components that could aect vehicle

performance and braking capabilities.

Loading...

Loading...