33

To install the Drive Belt:

If this procedure is not carried out as described, the edge

of the xed face may cut or damage the drive belt.

1. Positionthebeltaroundthedriverclutchrst.

2. Easethebeltovertheedgeofthexedfaceonthedriven

clutch and at the same time, turn the inside, movable face

clockwise.

Drive Belt alignment and tension are pre-set at the factory

and are not adjustable. They are critical for proper operation

of the drive system. Return the vehicle to an ARGO dealer if

rapid belt wear occurs.

7.2.2 CLUTCH MAINTENANCE

Disassembly and repair of the driver and driven clutch requires

special tools. Return the vehicle to an authorized ARGO dealer

if the clutch units need servicing. The following indicates that

clutch service might be required:

• a drop in vehicle performance

• the clutch does not shift smoothly

• the clutch sticks during vehicle operation

• the drive belt wears rapidly

• the vehicle vibrates severely during operation

• the vehicle does not accelerate when the engine speed is

increased with the transmission in gear

• transmission will not shift smoothly into gear at engine

idle.

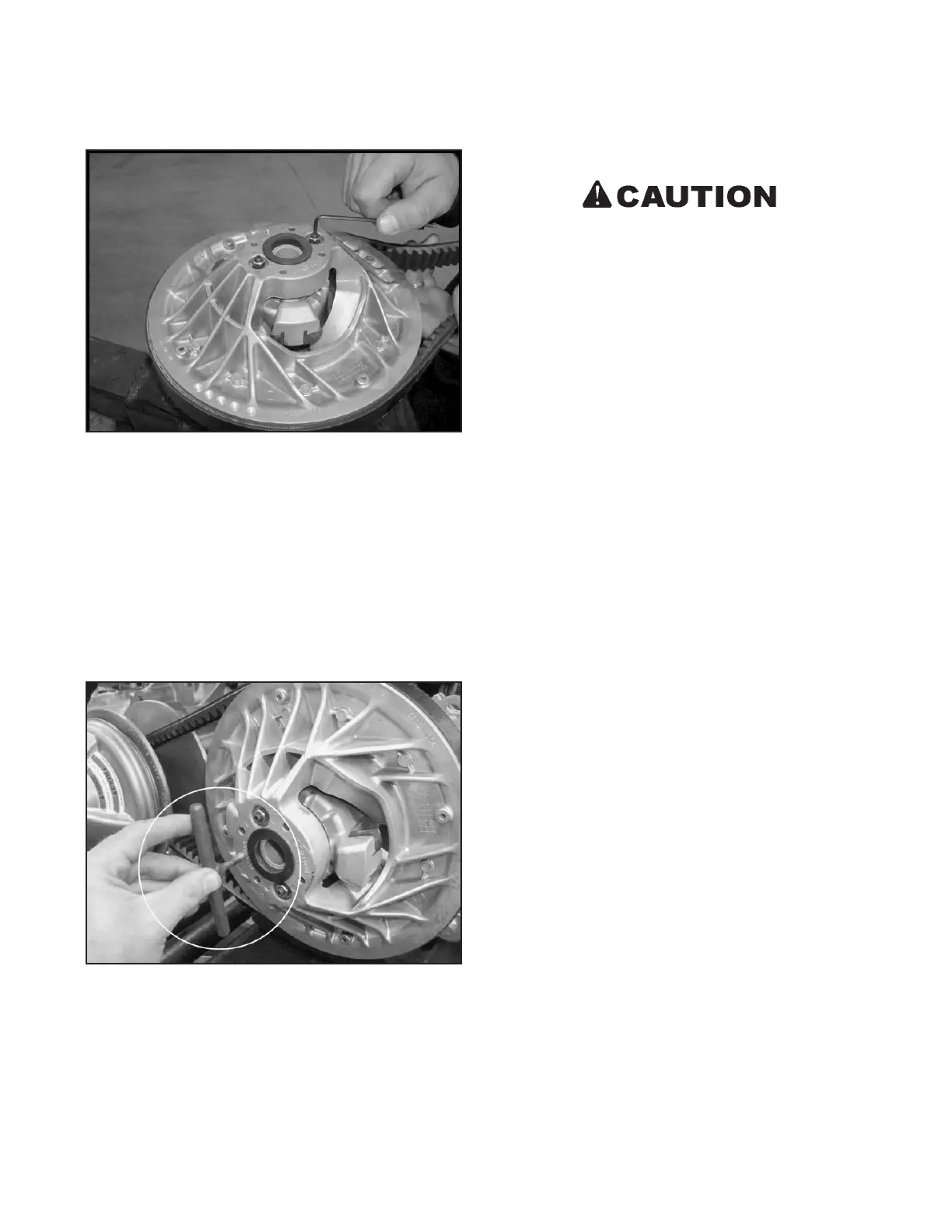

Clutch Inspection

Inspect the nylon sliders every 50 hours. The nylon sliders are

mounted in the driven clutch moveable pulley. (Figure 7-7).

When the clutch shifts, the cam moves on the nylon sliders.

Replace the nylon sliders before there is aluminium to alumin-

ium contact between the cam and the movable pulley. Driven

clutch disassembly is required to replace the nylon sliders

properly. Return the vehicle to an ARGO dealer for service

.

SECTION 7

MAINTENANCE INFORMATION

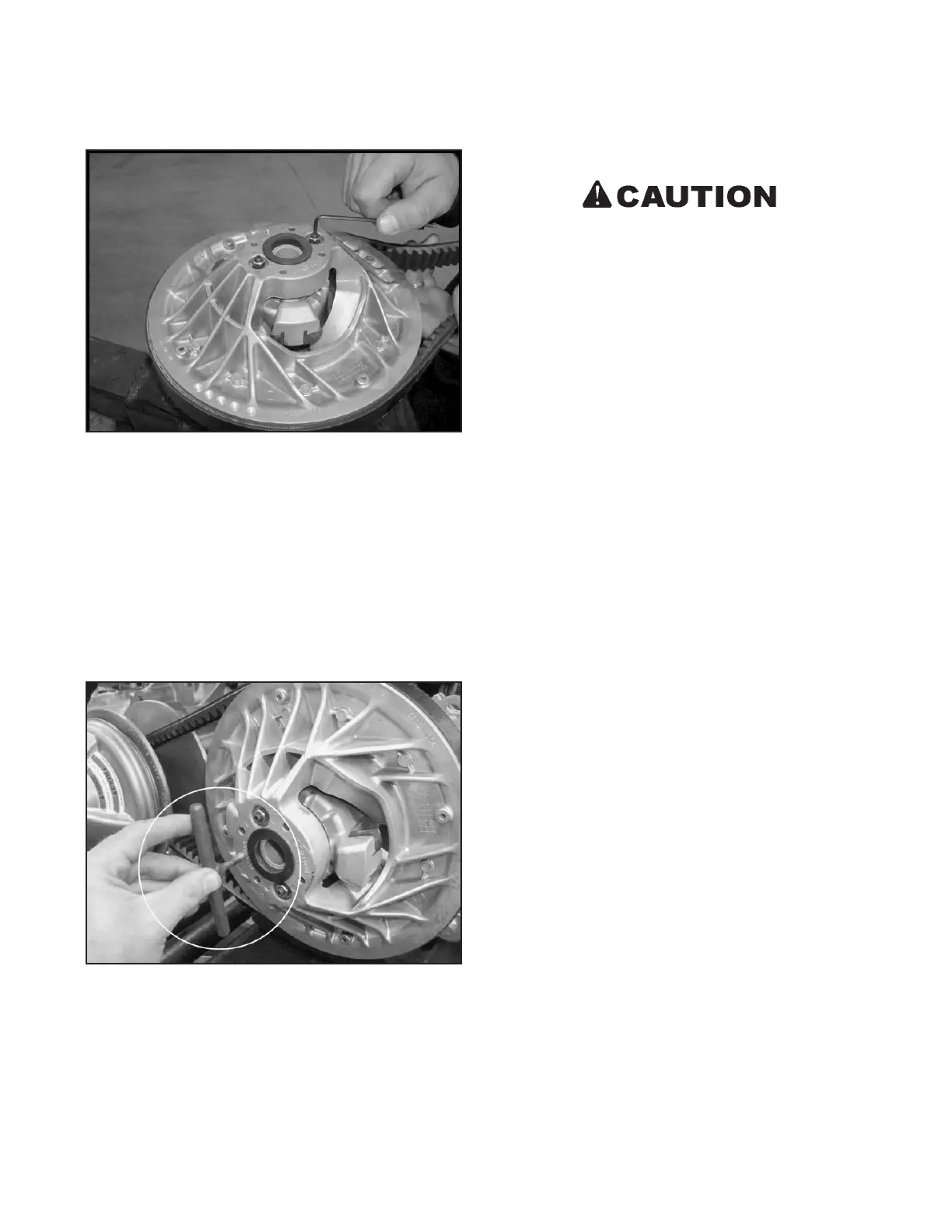

Figure 7-5 Turn the adjustment set screw.

To Remove the Drive Belt

The Invance Driven Clutch (transmission clutch), is

manufactured with a 6mm x 1.0 threaded hole in the clutch

face. This hole is provided to assist in spreading the driven

clutch pulleys apart by threading a 6mm x 1.0 thread bolt in

through the face. This bolt should be a least 2” in length with

full thread. Spreading the pulleys allows for easy removal

and installation of the 127-137HD or 127-159HD (Aurora

950 SX) drive belt. Figure 7-6.

Figure 7-6 Drive belt removal.

Loading...

Loading...