AZI Sales/Customer Service 800-528-7411 or 602-470-1414 or support@azic.com Page 13 of 105

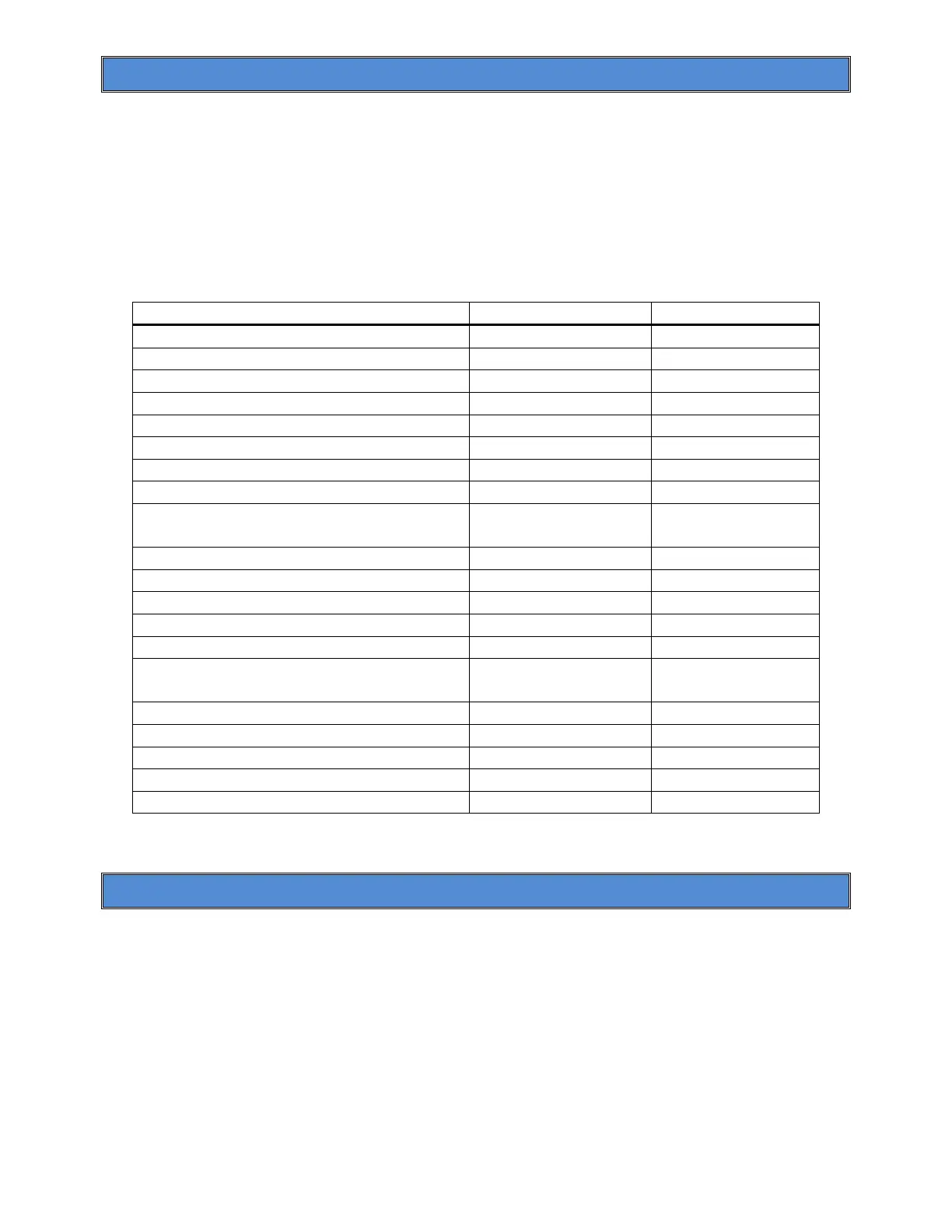

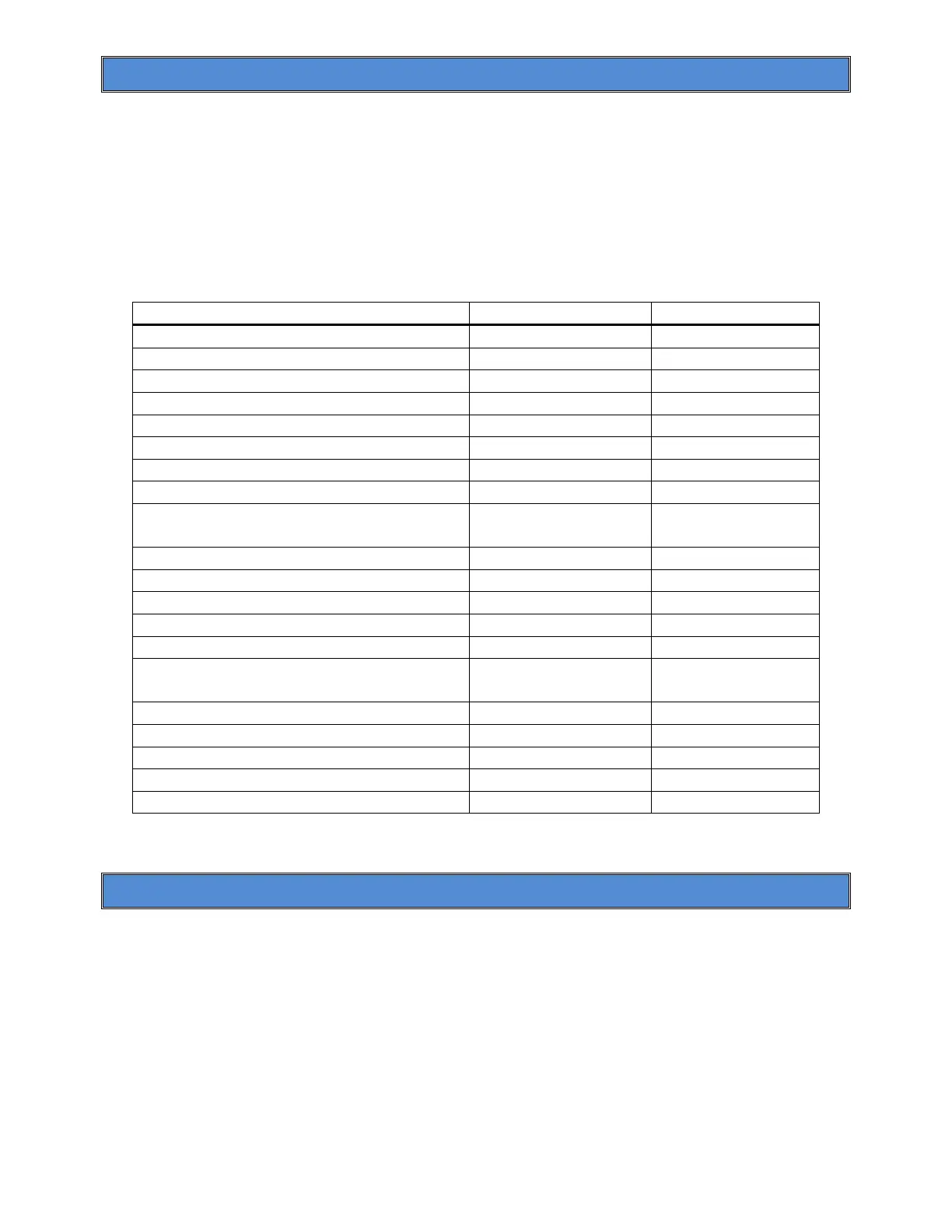

5.2. Instrument Models

There are 2 different instrument models in the MAX

®

4000 series, the MAX

®

4000 and the

MAX

®

4000XL, which have various feature differences, as detailed below. Throughout

this manual, MAX

®

4000 is used to refer to both the MAX

®

4000 and the MAX

®

4000XL

when describing common features or functionality. When there are specific differences

between the two models, these are indicated through the usage of MAX

®

4000XL for

features that are only available in the MAX

®

4000XL. Refer to the label on the front of the

instrument, the splash screen displayed during power-up or access the Special Features

menu (see page 79) to determine which model instrument you have.

Test Result Storage Count

Factory Test Program Count

Test Temperature Rate Control

Minimum Rate Setting for Rate Ending

Criteria

Result Resolution (decimal points)

Perform Temperature Calibration &

Verification

Requires Temp

Calibration Kit

Perform Balance Linearity Verification

Contact your technical sales representative for more information on the different models.

5.3. Oven

The sample oven is designed to remove volatile components from the sample as quickly

as possible, while maintaining accurate temperature control to prevent sample

degradation. Oven temperature is measured with a Resistance Temperature Device

(RTD), mounted in a rugged metal tube to prevent damage and dislocation. Temperature

control accuracy is within one degree of the set value after equilibrium is reached, and the

700-watt heater reaches equilibrium in 90 to 180 seconds, depending on the difference

between the starting and setpoint temperatures. Closed loop feedback control assures

a constant temperature even if power line voltage varies during the test. After a test is

completed, the heating system is turned off and the lid cooling fan is turned on. If

desired, open the lid after testing to speed cooling before performing the next test.

Loading...

Loading...