September 2003

HOW TO ORDER PARTS

Page 2

5300LN Series Parts & Service Manual

To order parts, use the appropriate part number and specify finish if necessary.

For example, to order 10 lockbodies for ten Entrance

Function (5307LN), use the following configuration:

Quantity Part Number Description

10 14-5307-0701-048 5307LN Lockbodies

-Please refer to the installation instructions for complete installation.

-For further assistance, contact your authorized YSG Door Security Consultants distributor or contact YSG directly at (800) 438-1951.

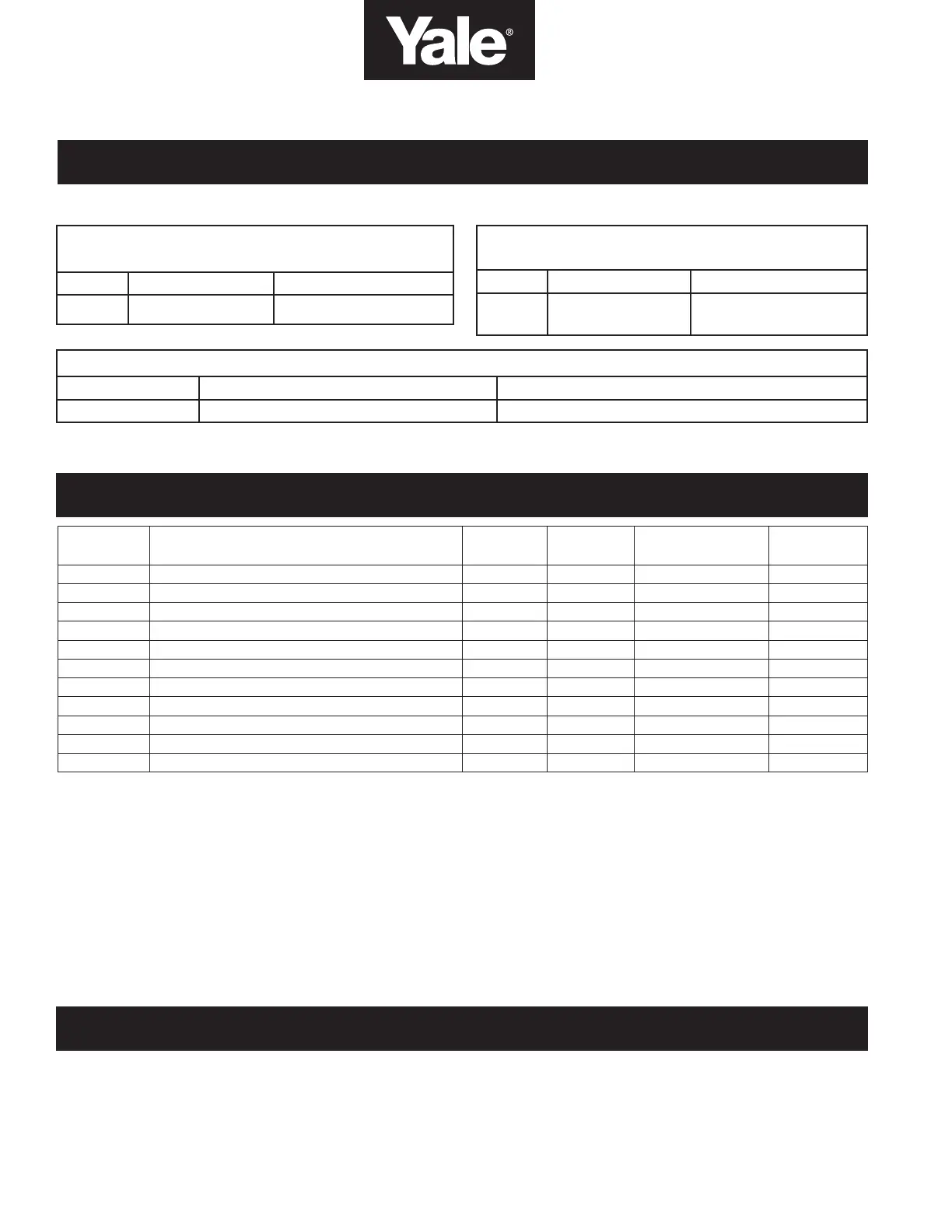

FINISH CHART

Finish Description Roses Levers

Pushbuttons/

Turnbuttons

Cylinder

Plugs

605* Bright Brass, PVD 003 043 043 004

606* Satin Brass, PVD 004 044 044 004

609 Satin Brass, Blackened, Satin Relieved 609 609 609 004

612 Satin Bronze 010 050 050 004

613 Dark Oxidized Satin Bronze, Oil Rubbed 007 060 060 004

613e* Dark Oxidized Satin Bronze, PVD 13e 13e 13e 004

616 Satin Bronze, Blackened, Satin Relieved 616 616 616 004

619 Satin Nickel 619 619 619 025

625 Bright Chrome 026 026 026 025

626 Satin Chrome 025 025 025 025

693 Black Powder Coat 200 200 200 025

To order 10 sets of Augusta Levers for an Entrance Function

in Satin Chrome, use the following specification:

Quantity Part Number Description

10 14-5300-6039-025

Outside AU Cylinder Lever

in 626

To order 10 plug retainers for the 1802 Key-in-Lever Cylinder, use the following specification:

Quantity Part Number Description

10 99-9999-4561-999 1802 Cylinder Plug Retainers

*PVD finish standard on 605 and 606. Available as an option on 613 (as 613e) for customers desiring a non-wearing finish.

PVD LIFETIME FINISH

Physical Vapor Deposition (PVD) is a technologically advanced finish coating that provides the ultimate surface protection against

environmental elements and everyday wear and tear. PVD matches clear coated finishes in appearance, yet surpasses them in

durability. Yale warrants all its PVD finishes against corrosion, tarnish, wear, discoloring and peeling for the lifetime of the part to

which it has been applied. Ask your sales representative for specific warranty information.

FINISH CARE

5300LN Cylindrical Locks are designed to provide the highest standard of product quality and performance. Care should be taken

to ensure a long-lasting finish. When cleaning is required, use a soft damp cloth. Using lacquer thinners, caustic soaps, abrasive

cleaners or polishes could damage the coating and result in tarnishing.

Ya le 5300LN Cylindrical locks are manufactured to be maintenance free under normal operating conditions and environments.

Subjection to extremely heavy traffic and/or particularly dusty and dirty environmental conditions, however, may eventually cause

unsatisfactory operation due to slow moving parts or sticking cylinders. In this case, it may be necessary to clean and re-lubricate

the lockset to maintain optimum performance. To clean the lockset mechanism, use a penetrating or solvent type lubricant to

loosen sticking components, then lubricate with lithium grease. To free sticking or jammed cylinders, lubricate with graphite or a

non-oily lubricant (such as Lock-EZE). Do not use petroleum-based lubricants in the cylinder keyway.

FINISHES

FINISH CHARTMAINTENANCE

Loading...

Loading...