BAG G

REMOVE THESE

PARTS FOR:

Steps 5-8

TOOLS USED

1:1

6925, qty 4

4-40 x 1/2 screw

6475, qty 4

6475, qty 4

3944, qty 2

spring, gold, front

3942, qty 2

spring, silver, rear

8846, spring preload spacer

qty 4 ea. 1/8"

qty 2 ea. 1/16"

1:1

6473, qty 4

3/32"

1:1

6472, qty 4

shock nut,

small

6299

6465

(#2)8844,

3964*

6299

step 3

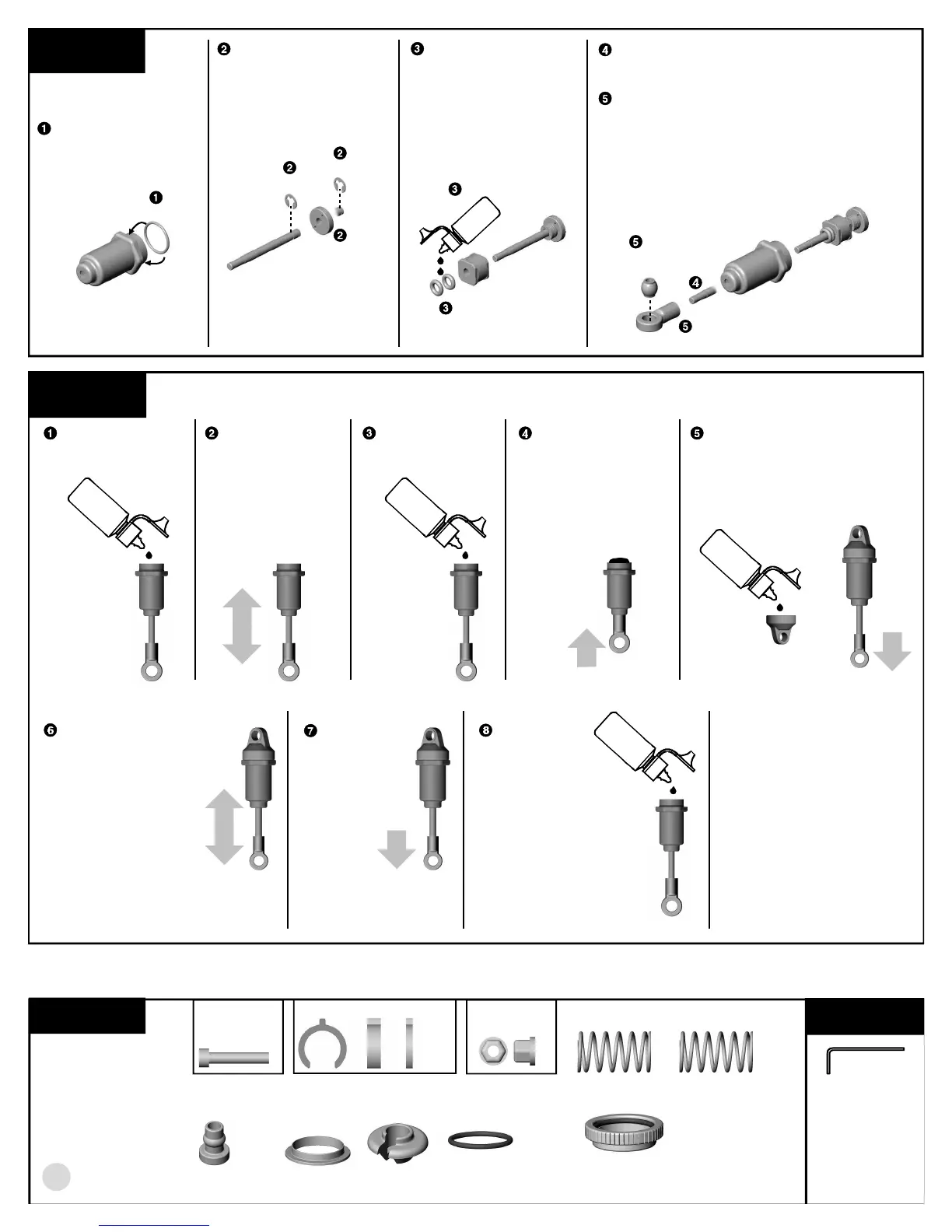

Insert the assembly into the shock body and pull

the shaft through firmly to seat the VC bobbin at

the base of the shock bore.

Push the #7217 pivot ball and eyelet together. As

you hold the shaft with a rag and needlenose

pliers next to threads, screw the eyelets onto the

end of the shock shaft.

TIP:

Use a permanent marker to mark your

shocks with an F and R to designate front and

rear.

RACER KIT ONLY:

8458

TEAM KIT ONLY: 8450B

FACTORY TEAM KIT: 3963*

6469

5407

7217 eyelet

7217

pivot ball

5423

OIL

6428

Holding the shock

upright, fill with oil

to the top of the body.

Slowly move the

shaft up and down

several times to

allow air bubbles

to escape to the top.

Refill with oil to the

top of the body.

Push the shaft up until

the piston is level with

the top of the body.

The oil will bulge up

above the shock body.

Fill The #6428 shock cap about

halfway with oil and install onto

the body. Try to retain as much

oil as possible during assembly.

The shaft will extend out as you

tighten the cap down.

step 4

SETTING THE

REBOUND

Move the shock shaft

in and out a few times

an then push it all the

way in. It should be

easy to push the shaft

in until the eyelet hits

the body

Then the

shaft should

push itself

out to its full

length very

slowly.

If the shock

does not push

out this far

there is not

enough oil in it.

Add just a little

oil and try

steps 6-7

again.

If the shock rebounds too

fast, or you cannot push the

shaft in until the eyelet hits

the body, there is too much

oil. Loosen the cap about a

full turn and pump out a small

amount of oil by pushing the

shaft in. Retighten the cap

and try steps 6-7 again.

Too much oil in the shock

will result in leakage.

9

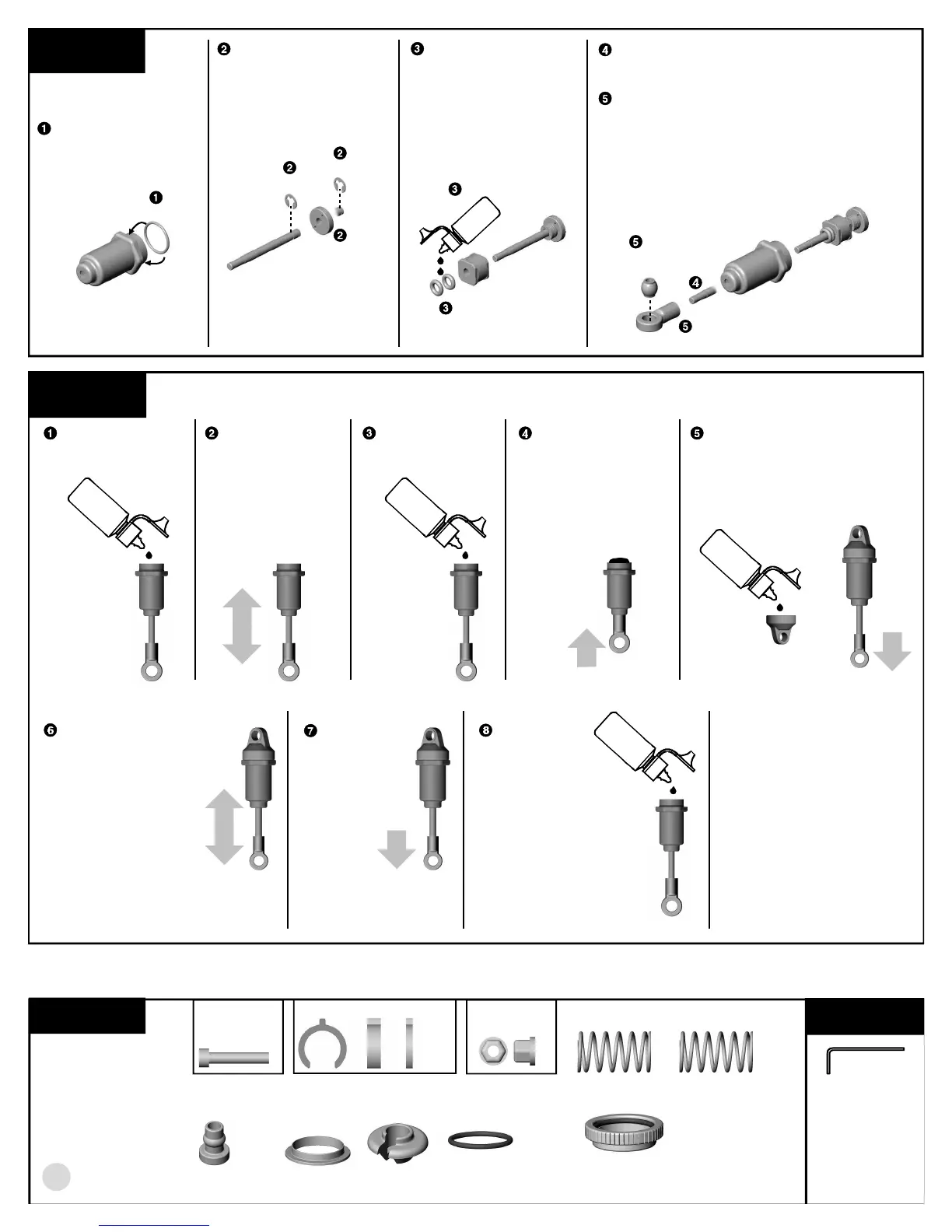

INTERNAL SHOCK

ASSEMBLY

(Assemble all four

shocks at once.) Install

the #6469 O-ring over

the threads of the

shock body.

On the #8844 (3964*)

shock shaft, install a

#6299 E-clip on both

sides of a #6465 (#2)

piston from step #1.

Slide the VC foam/

bobbin assembly over

the #8844 (3964*)

shaft and then two

#5407 O-rings. Place a

couple drops of oil on

the O-rings.

8844,

3964*

OIL

OIL

OIL

OIL

16

FACTORY TEAM ONLY

3963*, qty 4

FACTORY TEAM ONLY

3963*, qty 4

Loading...

Loading...