7 MAINTENANCE

103

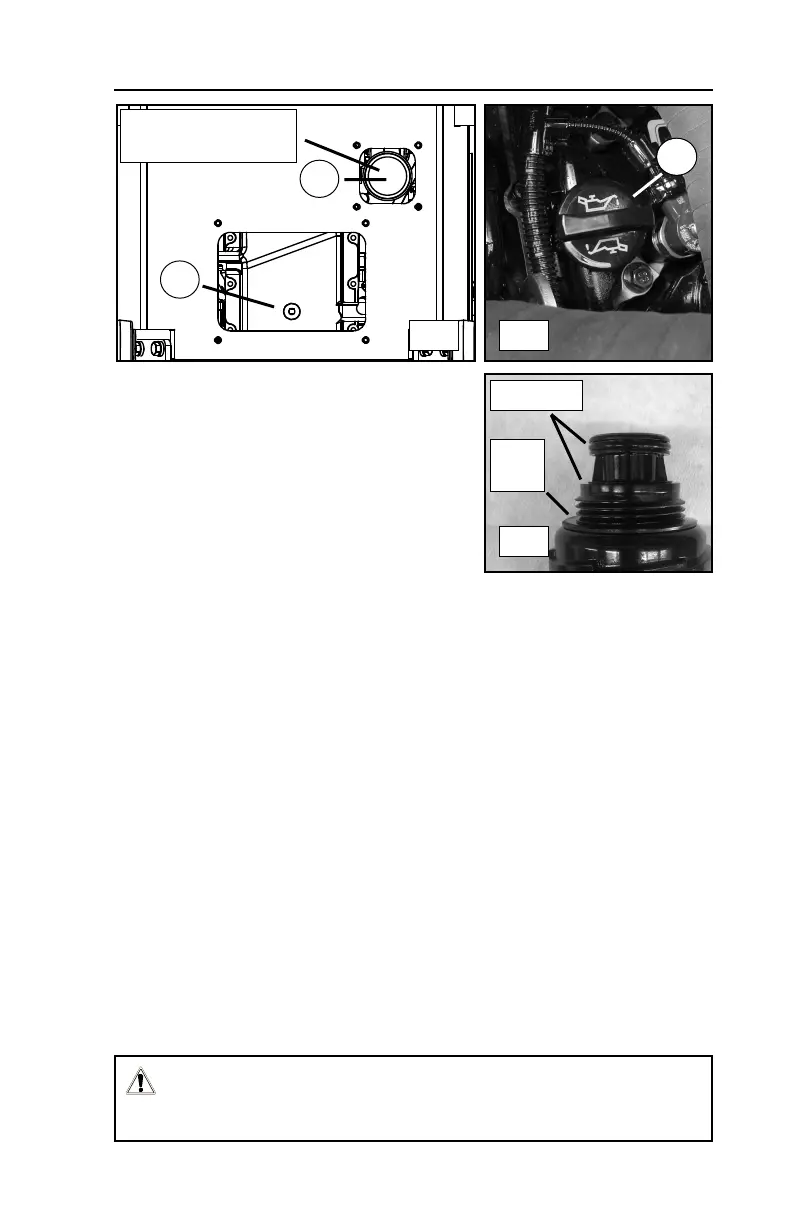

7.6 Engine Oil Change

Regular oil changes are necessary to maintain a

strong running engine. Change the oil at 500 hour

intervals (or every year if annual operating hours

do not exceed 500). Allow the machine to cool

prior to service. Wear safety glasses, safety gloves

and any other items necessary to ensure your

safety while performing maintenance or service.

To change engine oil:

1. Shut the machine down according to the procedure in section 5.13 and

allow the machine to cool thoroughly. Open the hood and side panels.

2. Lower the access covers beneath the engine to access the oil drain and

filter.

3. Remove the oil drain plug (item 1, fig. 7.6-1) from the bottom of the pan.

4. Drain the oil into a suitable catch container.

5. Remove the engine oil filter (item 2, fig. 7.6-1).

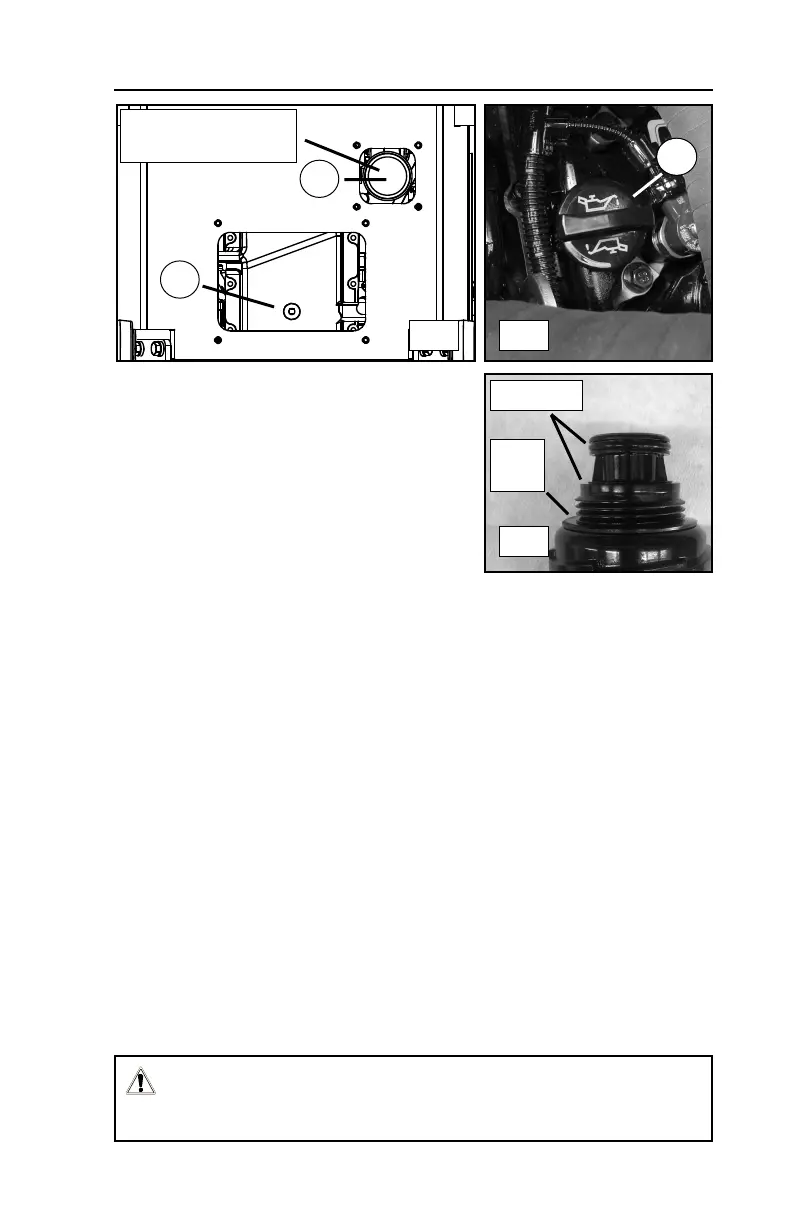

6. Apply fresh oil to the upper two oil filter seals only, (lower seal and engine

sealing surface must be clean and dry) and install the new filter (fig. 7.6-3).

7. Using a 1/2” ratchet and appropriate extension, torque the new oil filter to

29.5 Lb. ft (40 Nm) from the bottom through the chassis access opening.

8. Reinstall the oil drain plug as found upon removal and tighten.

9. Refill the engine to capacity at the location labeled 3 above with oil as

specified in chapter 3, Technical Data.

10. Re-secure the access covers as found upon removal, close hood and side

panels. Dispose of the used oil and filter according to mandates.

Oil and machine components can be HOT! Allow the machine to cool

thoroughly prior to performing maintenance or service to avoid the possi-

bility of burns.

RT-75 / RT-75HD US O&M

0405-073 2020-07

7.6-1 7.6-2

3

1

2

7.6-3

lubricate

Clean

& Dry

Torque Specification:

29.5 Lb. Ft (40 Nm)

Loading...

Loading...