5 OPERATION

82

5.3 Starting Procedure

Before starting the engine, perform the pre-operation safety checklist. Once com-

plete, you may proceed by following the procedure below. See section 4.11 for

information regarding password protection and accessing user profiles at startup

through the premium operator interface (if equipped).

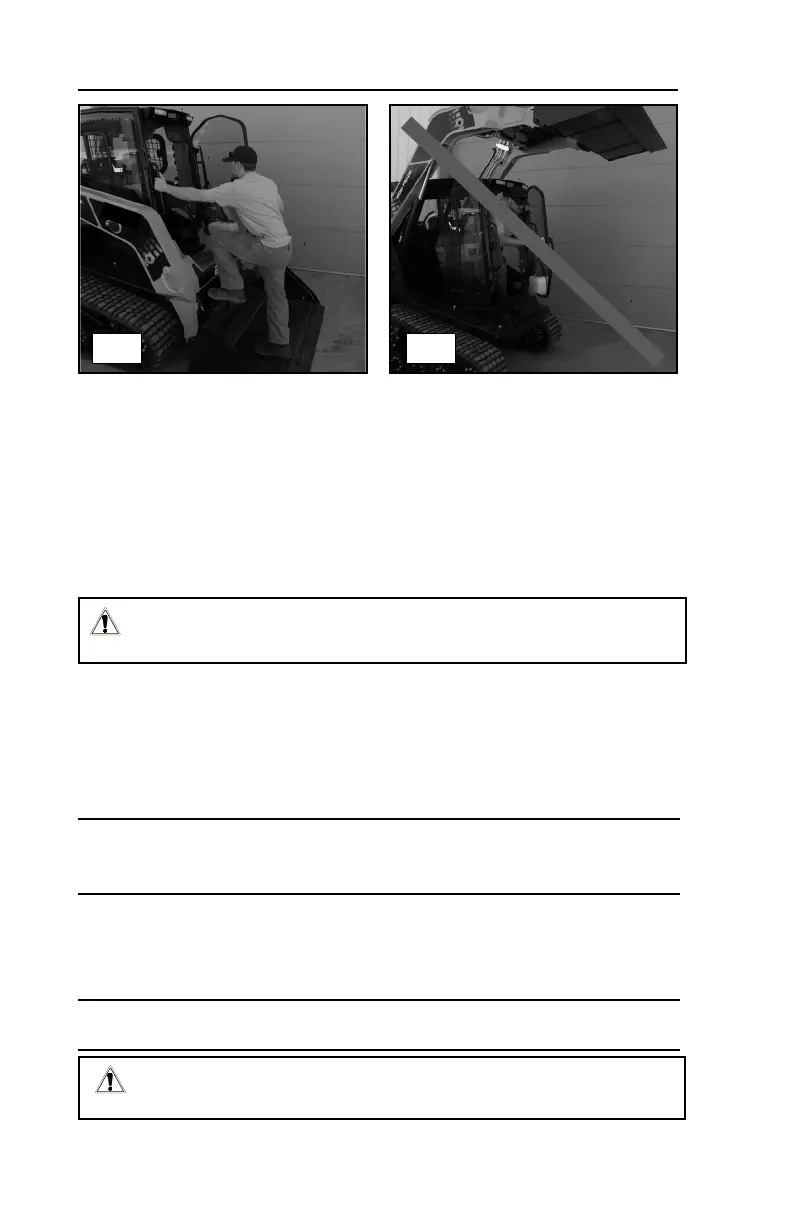

1. Enter machine with lift arms all the way down. Maintain three points of contact

(defined as: one foot and two hands, or one hand and two feet) with the

machine (fig. 5.3-1).

2. Sit down into the operator’s seat, fasten the seat belt, then lower the lap bar.

3. Position the throttle in the SLOW (turtle icon) position.

4. Turn the ignition key to the on position to “pre-heat” the ignition system.

While this occurs, the pre-heat operation light will illuminate.

5. Once the pre-heat operation light goes out, turn the ignition key to the

right to start the engine.

Note: If the engine is cranked for over 30 seconds (within a 2 minute period), the

ignition will “lock out” (for 2 minutes). During this time, an indicator lamp will

flash (key in “on” position). Once the lamp goes out, restart may be attempted.

6. With the exhaust adequately vented, bring the engine and hydraulic oil up to

operating temperature. Low oil temperatures can cause the control system

to respond sluggishly.

7. Set the throttle to desired rpm for operation.

Note: The parking brake is automatically engaged when the engine is turned off,

the operator is not in the seat or the lap bar is raised.

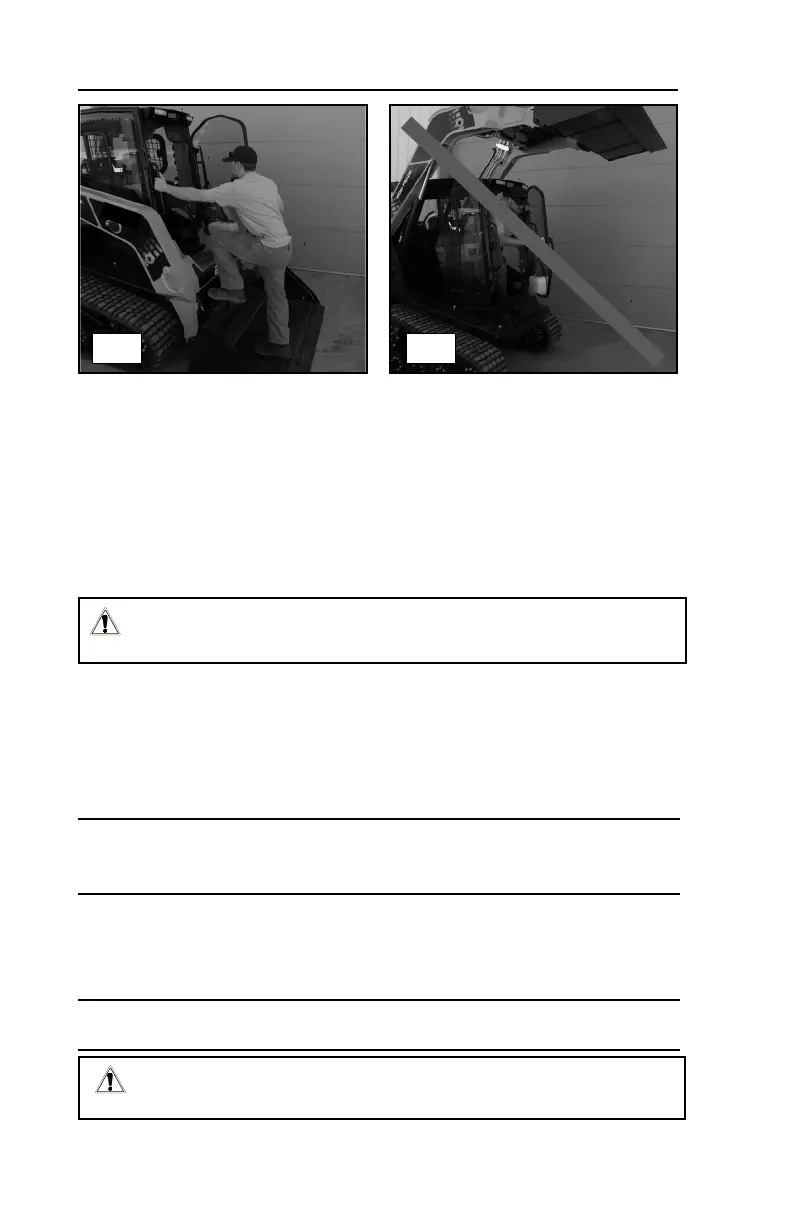

Entering or exiting the vehicle under raised lift arms could result in injury

or death. Never allow anyone beneath raised, unsecured lift arms.

RT-75 / RT-75HD US O&M

0405-073 2020-07

Personal Protective Equipment should be worn during operation in

accordance with section 2.5 of this manual.

5.3-1 5.3-2

Loading...

Loading...