For compressors with integrated dryer: Minimum

setting

Factory

setting

Maximum

setting

Delay at signal sec 0 3 10

Delay at starting sec 0 255 255

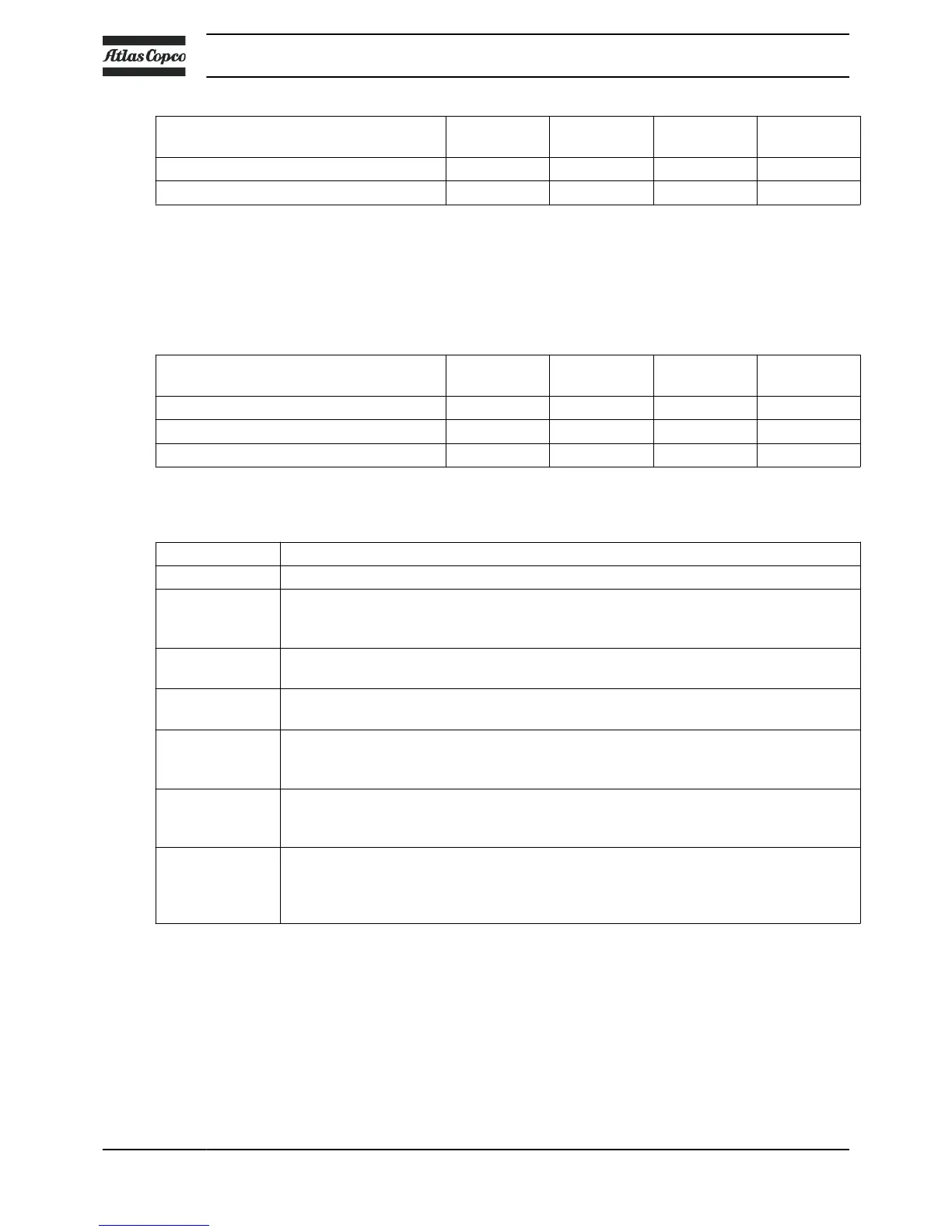

Service plan

Also see section Preventive maintenance schedule.

Consult Atlas Copco if a timer setting has to be changed. The intervals must not exceed the nominal

intervals and must coincide logically. See section Modifying service plans.

Minimum

setting

Factory

setting

Maximum

setting

Service plan A (operating hours) hr 4000

Service plan B (operating hours) hr 4000

Service plan C (operating hours) hr 8000

Terminology

Term Explanation

ARAVF Automatic restart after voltage failure. See section Elektronikon regulator II.

Compressor

element outlet

The regulator does not accept illogical settings, e.g. if the warning level is programmed

at 95 ˚C/203 ˚F, the minimum limit for the shut-down level changes to 96 ˚C/204 ˚F. The

recommended difference between the warning level and shut-down level is 10 ˚C/18 ˚F.

Delay at shut-

down signal

Is the time for which the signal must exist before the compressor is shut down. If it is

required to program this setting to another value, consult Atlas Copco.

Oil separator Use Atlas Copco oil separators. The recommended maximum pressure difference is 1

bar/15 psi.

Power recovery

time

Is the period within which the voltage must be restored to have an automatic restart. Is

accessible if the automatic restart is activated. See Elektronikon II regulator. To activate

the automatic restart function, consult Atlas Copco.

Minimum stop

time

Once the compressor has automatically stopped, it will remain stopped for the minimum

stop time, whatever happens with the net air pressure. Consult Atlas Copco if a setting

lower than 20 seconds is required

Unloading/

Loading pressure

The regulator does not accept illogical settings, e.g. if the unloading pressure is

programmed at 7.0 bar(e)/101 psig, the maximum limit for the loading pressure changes

to 6.9 bar(e)/100 psig. The recommended minimum pressure difference between

loading and unloading is 0.6 bar/9 psig.

Instruction book

52 API603130

Loading...

Loading...