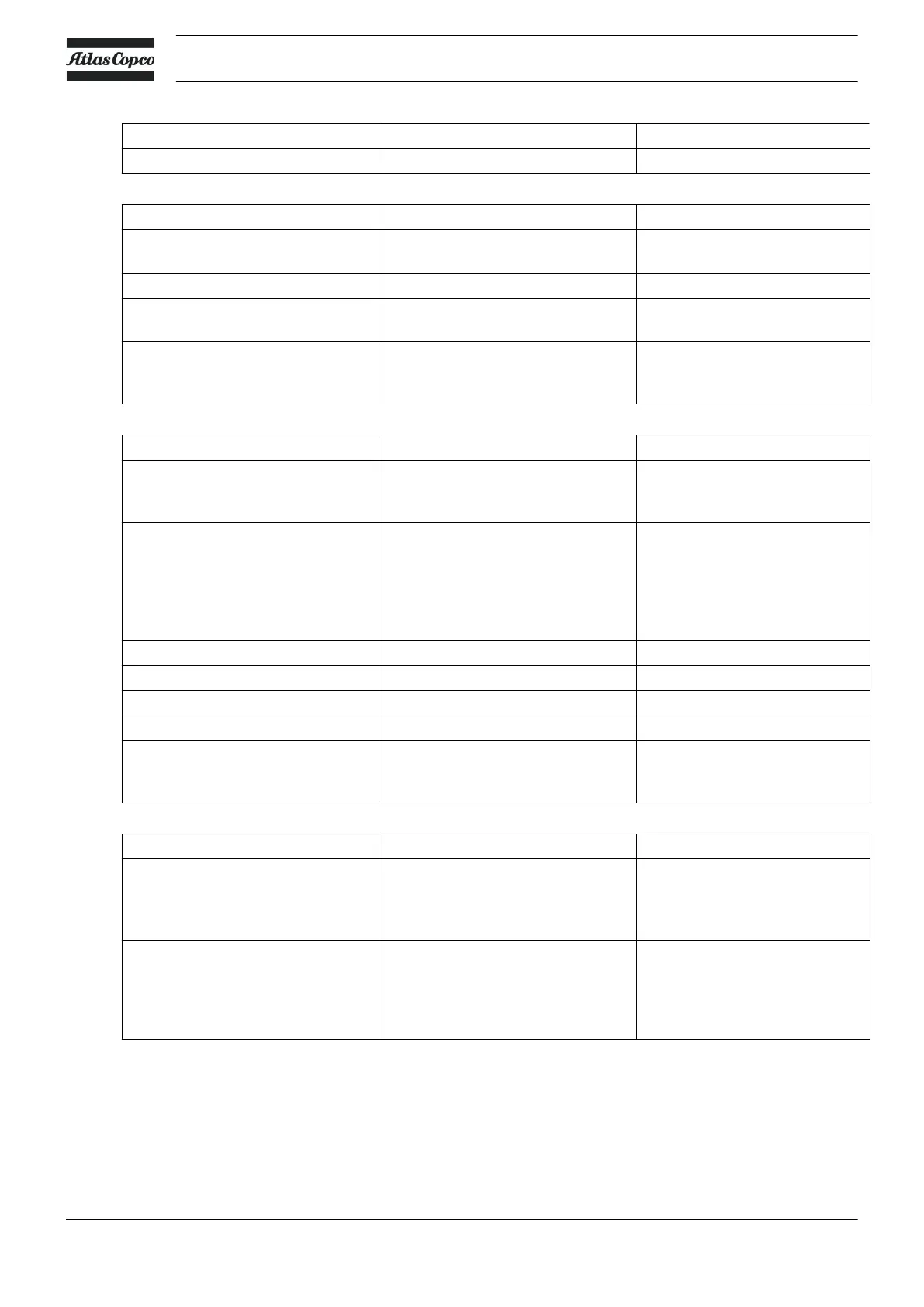

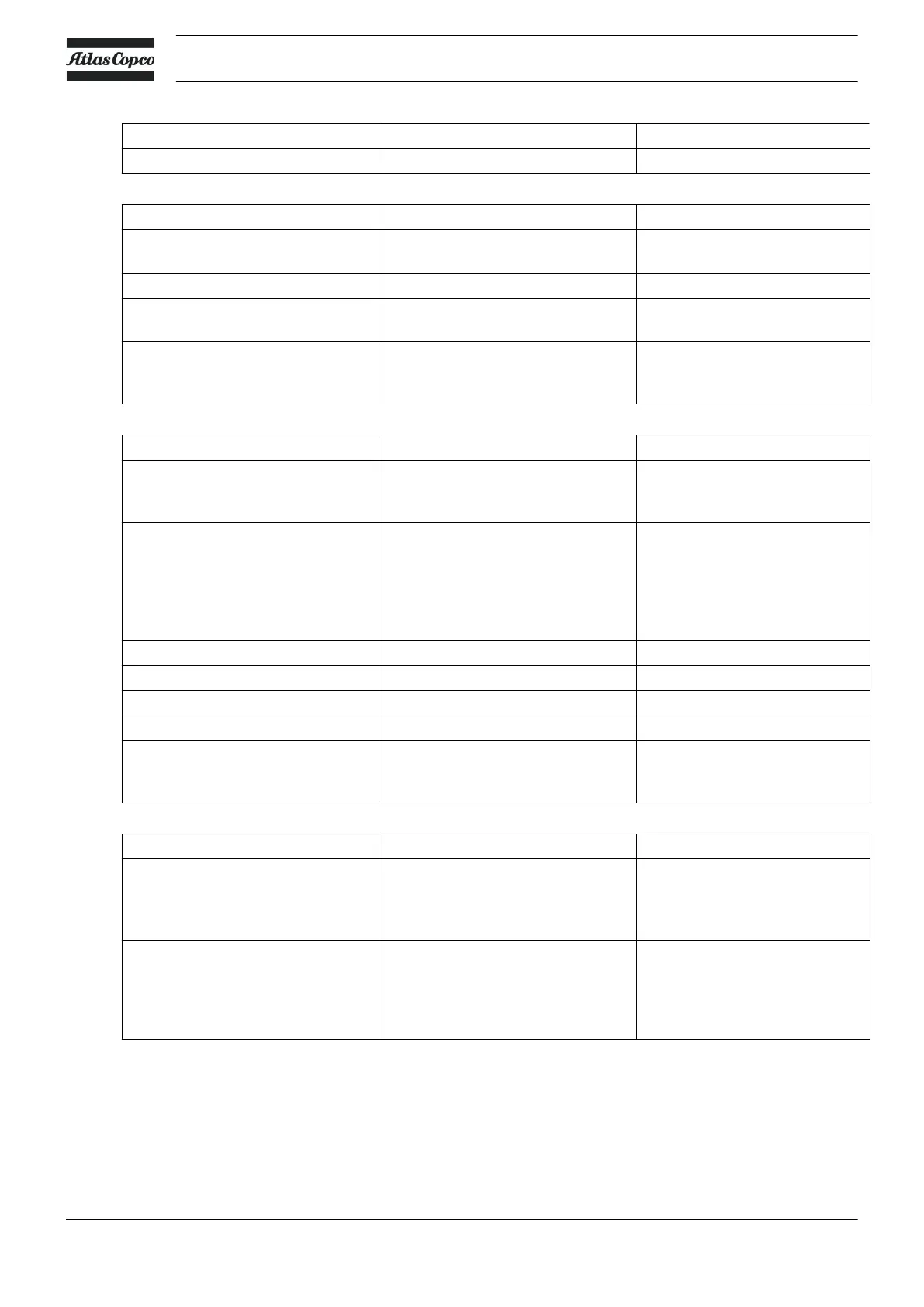

Condition Fault Remedy

Compressor element out of order Consult Atlas Copco

Condition Fault Remedy

Safety valve blows Minimum pressure valve

malfunctioning

Check and have defective parts

replaced

Oil separator clogged Have element replaced

Safety valve out of order Have valve checked. Replace if

necessary

On Full-Feature compressors, dryer

piping clogged due to formation of

ice

Have system checked by Atlas

Copco

Condition Fault Remedy

Compressor element outlet

temperature or delivery air

temperature above normal

Oil level too low Check and correct, see

Operation instructions / During

operation

On air-cooled compressors,

insufficient cooling air or cooling air

temperature or relative humidity is

too high

Check for cooling air restriction

or improve ventilation of the

compressor room. Avoid

recirculating of cooling air. If

installed, check capacity of

compressor room fan

Oil cooler clogged Clean cooler

By-pass valve malfunctioning Have valve tested

Air cooler clogged Clean cooler

Compressor element out of order Consult Atlas Copco

Degraded oil Check service intervals, see

Preventive maintenance

schedule

Condition Fault Remedy

Low Load Alarm triggered:

Compressor running with too low oil

temperature over a longer period of

time

Solenoid valve malfunctioning Replace valve

Extreme low usage of compressor Increase loading profile (longer

and/or more load cycles

required)

If not possible, consult Atlas

Copco

Converter fault codes

If a problem is detected by the converter, a specific code (Main motor converter alarm) will appear on the

Elektronikon display, together with a fault code. Below table lists the most important error codes. If

another code appears, please contact Atlas Copco.

Instruction book

114 2920 7109 23

Loading...

Loading...