22 23

Sustainability

Using Turbo Tight

®

results in shorter tightening cycles. This in turn

means less heat development and a cooler tool. It also helps to reduce

energy consumption with 10 % and prolong tool lifetime in high-cycle

environments. In general the losses during a tightening can be reduced by

speeding up the tightening phase, but remember: the big savings come

from standby.

How are cycle times reduced?

Turbo Tight

®

controls the motor speed to achieve the fastest possible

tightening without excessive overshoot. Comparing it to a traditional Two

Step strategy, Turbo Tight

®

runs faster for a longer period.

How is reaction force reduced?

Turbo Tight

®

uses the tool’s mass moment of inertia to reduce the reaction

force transmitted to the operator. The increased control of the motor in

combination with the fast dynamic regulation enables the tool to minimize

the reaction force from the tightening.

How come set-up is so easy?

Turbo Tight

®

is a strategy that controls the motor speed based on the actual

torque rate and the remaining torque of the joint. Since all these parameters

are dynamically calculated during the tightening, the only user input

required is the target torque.

How does Turbo Tight

®

provide energy savings?

Atlas Copco has been ISO 14001 certified since 2010, ensuring the planning,

execution, control and optimization of continuous improvement processes

for all Atlas Copco Industrial Technique products. If we compare the energy

consumption of a Power Focus 4000 running a Tensor ST tool with a Two

Step set-up, with the energy consumption of a Power Focus 600/6000

running a Tensor ES/STR tool with Turbo Tight

®

, we get the following result.

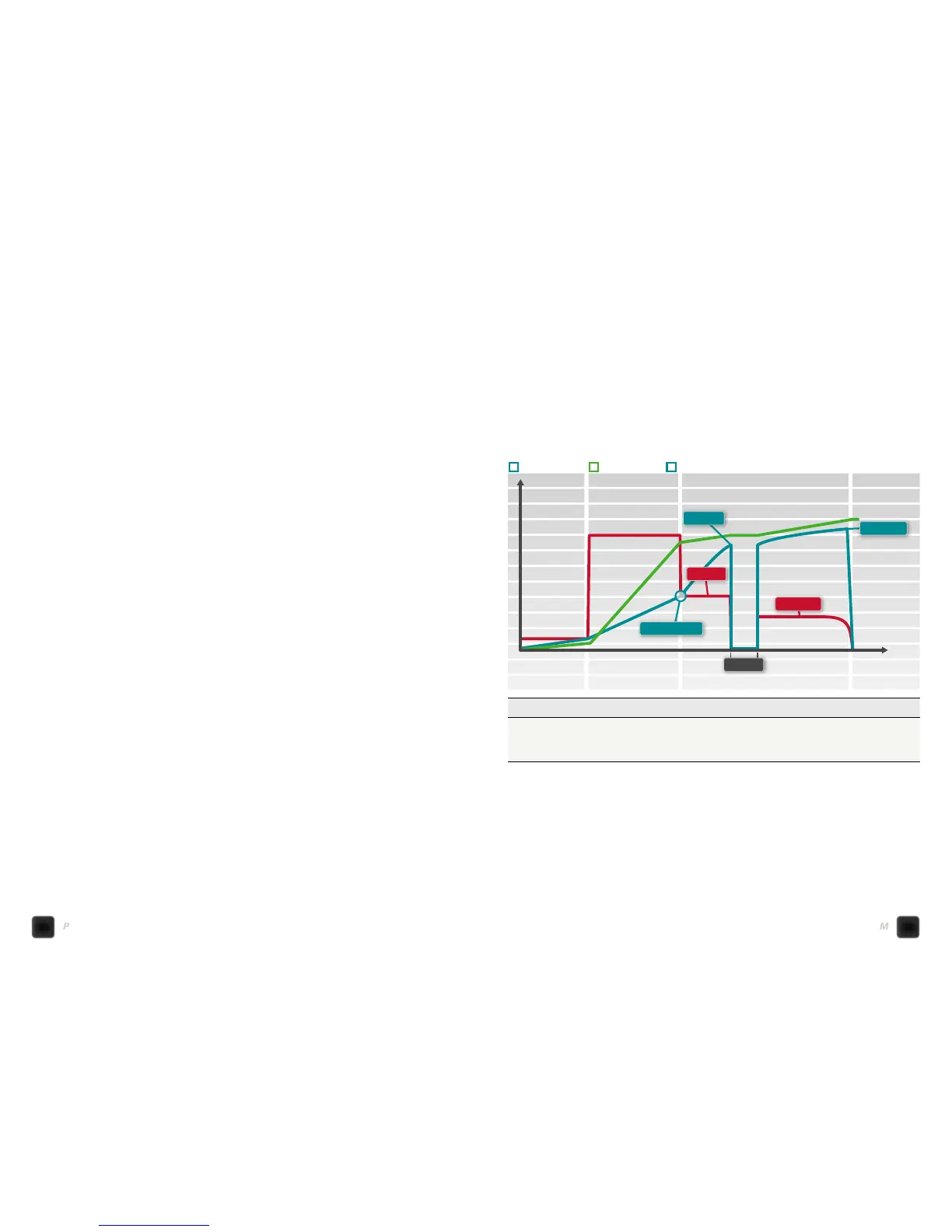

Target Speed

Pause Time

Target Torque

First Torque

Rundown Complete

First Speed

Start Stop

TIME

TORQUE/TIME ANGLE/TIME SPEED/TIME

Rundown Tightening

Two Step Tightening Strategy

The two step tightening strategy is very similar to the Quick step strategy

with the exception that it adds a small time delay between the first step and

the final step, to further counteract short-term relaxation effects in the joint.

Fine-tuning the Two Step Tightening strategy

When the First target is reached the tool will make an immediate stop for a

specified time before it continues with the final step. The First torque value

and the Pause time should be chosen to improve ergonomics for hand-held

tools.

Parameter Description Default Value

First torque Target torque for the first step

First speed Target speed for the first step

Pause time Time between first and second step 50ms

Loading...

Loading...