40 41

CABLE MANAGEMENT

Cables are used in conjunction with all Atlas Copco tools and assembly

equipment, including: hand held tools, fixtured hand tools or when spindle

”motors only” are provided for incorporation into various types of machine

automation.

As with many industrial systems, cables are a main failure point – especially

in applications where the cables are subject to repetitive motion. Atlas

Copco has the knowledge to help the customer find effective solutions to

their facilities unique cable needs.

In the case of fastening equipment, cables connect the following functions:

• Power supply

• Controller

• Nutrunner

• Accessory

With a proper cable management

you will increase the life of

the cable and reduce the risk

operators falling over them. In

example, using a cable balancer

helps to manage the excess cable

when the tool and cable are not

extended.

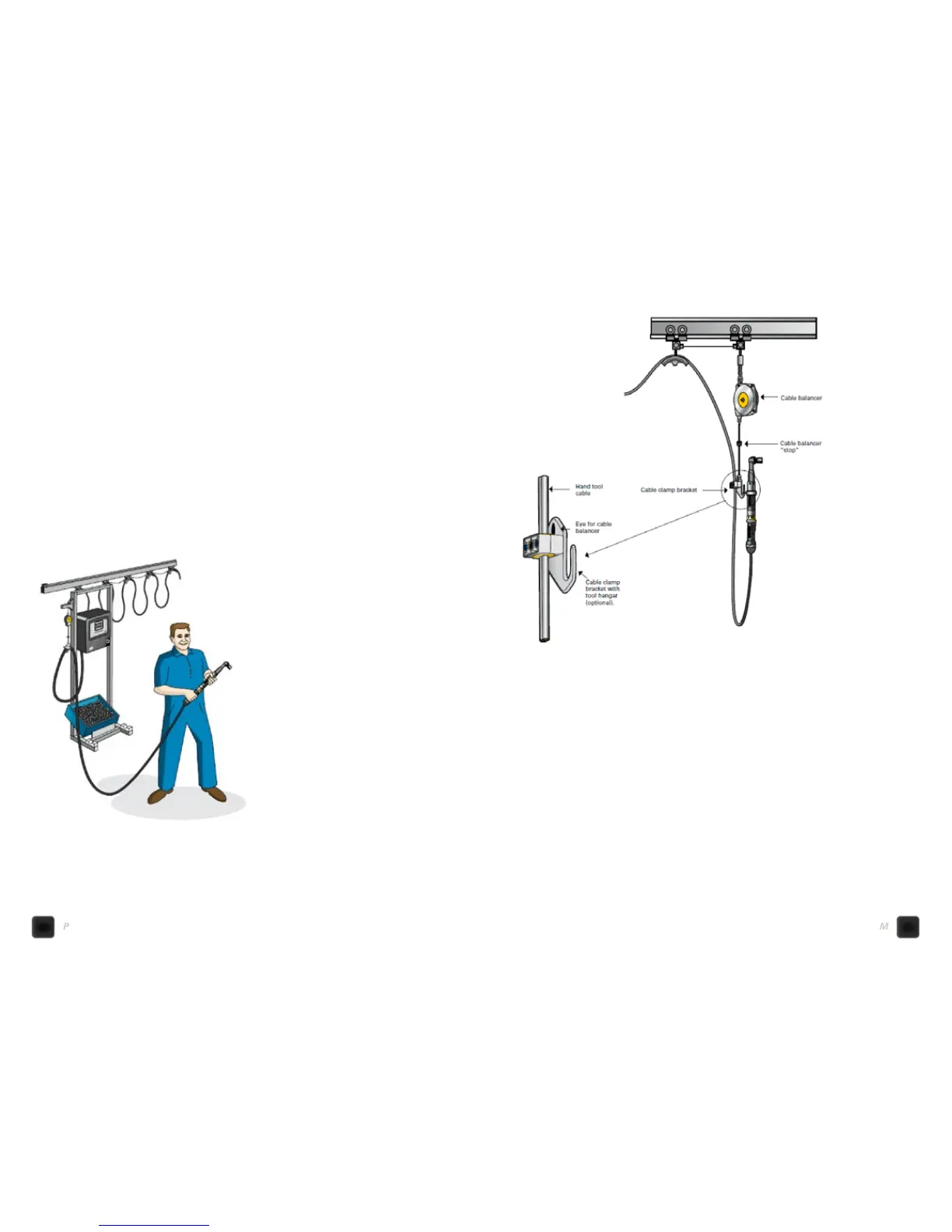

Use of a cable clamp bracket

This clamp bracket can be attached to a hand tool cable and then be attached

to a cable balancer. When located properly on the tool cable, the cable

balancer will keep the cable off the floor. A hook is provided as a place to

“rest” the tool and may be used with or without a cable balancer to “rest”

the tool when the cable is spread over the cable shoe.

Loading...

Loading...