44 45

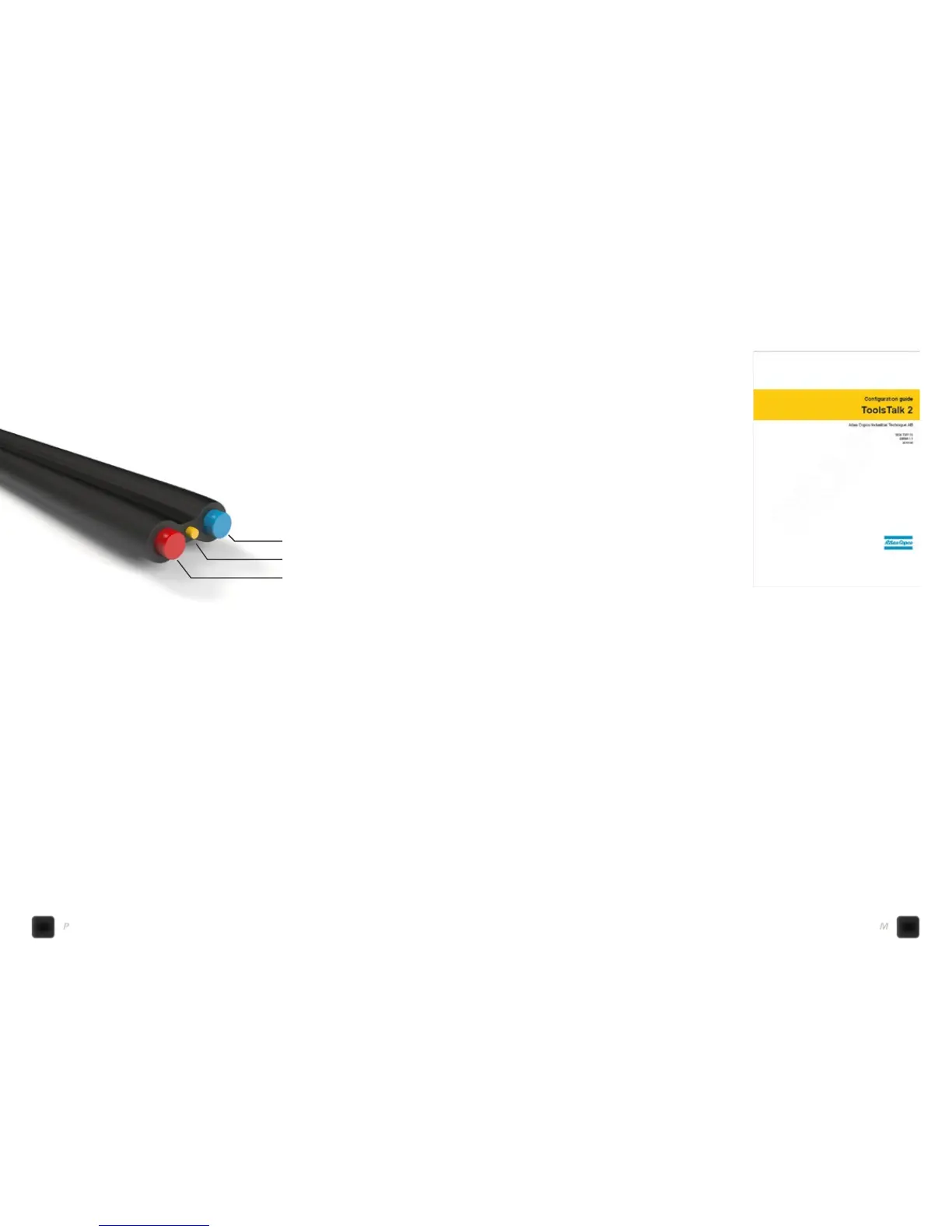

Centralized strain relief to prevent lead damage

The flat-cable design features a Kevlar-reinforced core, to absorb the

tensile loads to which cables can be subjected in tough applications. When

subjected to high tensile loads, this centralized load-relief Kevlar core also

prevents cable leads being damaged or compressed. For maximum signal

integrity, the flat cable design also ensures optimum separation of high and

low voltage conductors.

For more information regarding cable management please look in the cable management

pocket guide (9833 1640 01). In this pocket guide you will find more information regarding cable

management for fixtured and hand held tools and check points before, during an

FIELDBUS

Fieldbus is an industrial network system

for real-time distributed control. It is a way

to connect instruments in a manufacturing

plant, for example Power Focus controllers.

Fieldbus works on a network structure which

typically allows daisy-chain, star, ring, branch,

and tree network topologies. The fieldbus

requires only one communication point at

the controller level, and allows hundreds of

analog and digital points to be connected at

the same time. This reduces both the length

of the cable required and the number of

cables required. Furthermore, since devices

that communicate through fieldbus require a

microprocessor, multiple points are typically

provided by the same device. Some fieldbus

devices now support control schemes such

as PID control on the device side instead of

forcing the controller to do the processing.

The Power Focus 6000 currently (release 2.1)

supports three different fieldbus types:

• DeviceNet

• EtherNet/IP

• ProfiNetIO

You can set up the fieldbus parameters using Tool Talk 2. For a full overview

of how this is done, please see the user guide for Tool Talk 2.

In short, the value of using a fieldbus communication is to have a real-time

control over multiple controllers in a standardized way in your production

plant.

Please note that there are a couple of fieldbus types available in the Power

Focus 4000 that are not yet implemented on the Power Focus 6000 platform.

Low

Kevlar

High

Loading...

Loading...