14 15

Basic Programming

The power focus 6000 tightening programs

need parameters such as target torque or

target angle to be set in order to perform a

tightening. Other settings – soft start, self

tap, and torque compensation – are optional,

just as setting which tightening strategy

to use. Monitor the tightening progress

by adding limits for torque, or specified

tightening angle.

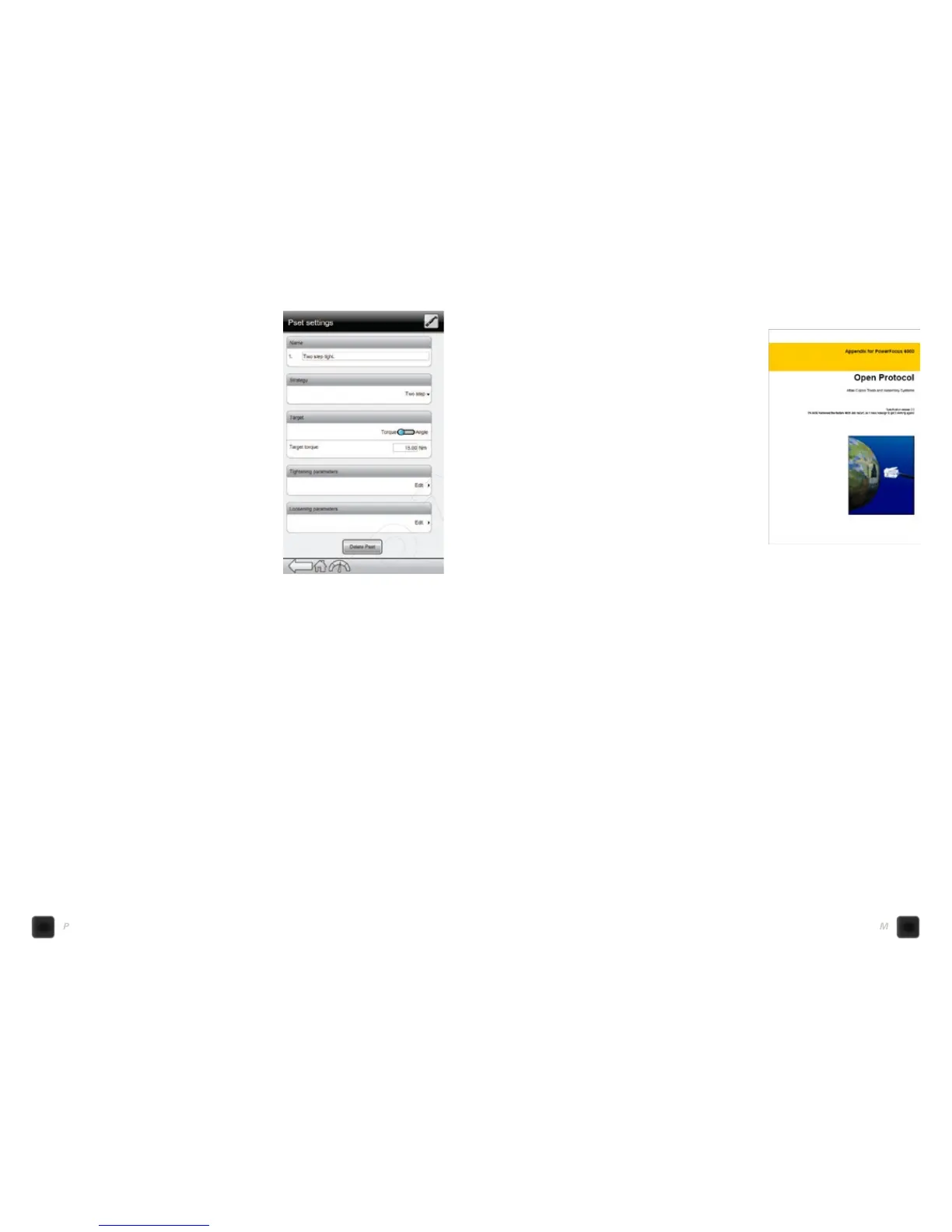

In the general Pset settings you can set up

and manage the Psets by naming them and

making general tightening settings. Choose

tightening strategy, manual or quick prog

mode, and set the Pset target value.

To the right you can see a configured Pset

named Two step tight that uses a two step

tightening strategy set to the Target torque of

15 Nm

By clicking on “two step” in the strategy

box you can change strategy from two step

to TurboTight etc. Find more configuration

options by clicking on edit under tightening

parameters or loosing parameters.

For more information regarding

programming please use the power focus

6000 configuration guide with detailed

information on each menu item and the

configuration.

Open Protocol

The Power Focus 6000 enables communication

trough open protocol. The Atlas Copco Open

Protocol is a standard communication protocol

developed to facilitate communication

between our controllers and external parties in

the customer’s production processes.

Open Protocol is an interface for building

applications for remote control or data

subscription of controllers. It is platform

independent and can be implemented

on Linux, PLC, printers, and all Windows

platforms. The Open Protocol supports

Ethernet connection with the Power Focus

6000.

An Open Protocol message consists of

three parts; header, data field and message

end. Depending on type of communication,

a package includes the message and an

encapsulation before and after.

The MID, or message ID, is represented by a

four digit number (for example MID 0062 for

Vehicle ID Number upload). Each MID can have several revisions. Usually

a new revision is created when more data is included and the length of

the message needs to be increased. MID revisions are added to ensure

backwards compatibility.

For a full overview of what information, or MIDs (Message IDs) and

revisions, are supported with the Power Focus 6000 please see the Open

Protocol Appendix (picture above) provided in the Marketing and Support

Web Portal. The main value with Open Protocol is to provide a standard

and easy-to-use communication protocol. It can be set up in minutes and

integrated with your production processes in your plant. Through the years

“Open Protocol” has become an industry standard to communicate with

tightening equipment on assembly lines.

Loading...

Loading...