- 53 -

5.3 Alternator maintenance

procedures

5.3.1 Measuring the alternator

insulation resistance

A 500 V megger is required to measure the alternator

insulation resistance.

If the N-terminal is connected to the earthing system,

it must be disconnected from the earth terminal.

Disconnect the AVR.

Connect the megger between the earth terminal and

terminal L1 and generate a voltage of 500 V. The

scale must indicate a resistance of at least 5 MΩ.

Refer to the alternator operating and maintenance

instructions for more details.

5.4 Engine maintenance

procedures

Refer to the Engine Operation Manual for a full

maintenance schedule.

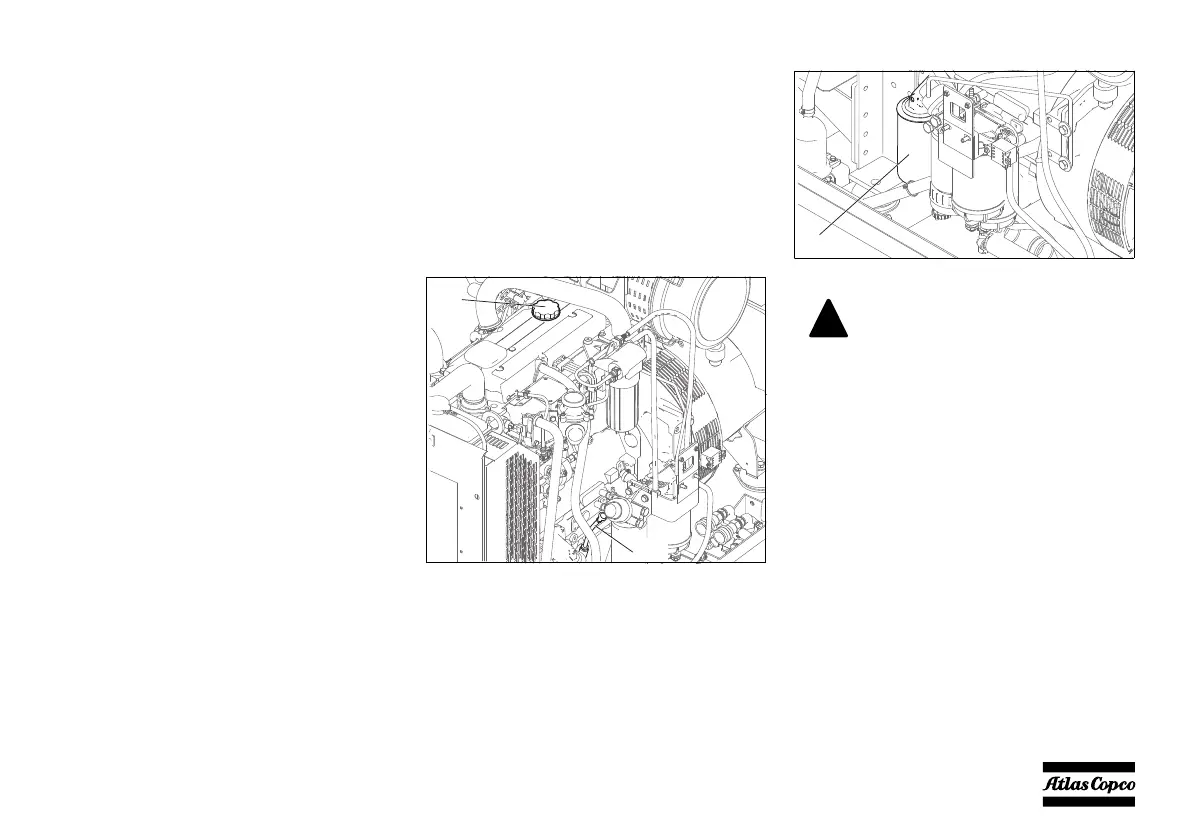

5.4.1 Engine oil level check

Consult the Engine Operation Manual for the oil

specifications, viscosity recommendations and oil

change intervals. For the intervals, see also section

“Maintenance schedule” on page 46.

– Check the engine oil level by using the oil level

dipstick (OLD).

– Top up with oil (FCO), if necessary.

Refer to the Engine Operation Manual for more

detailed instructions.

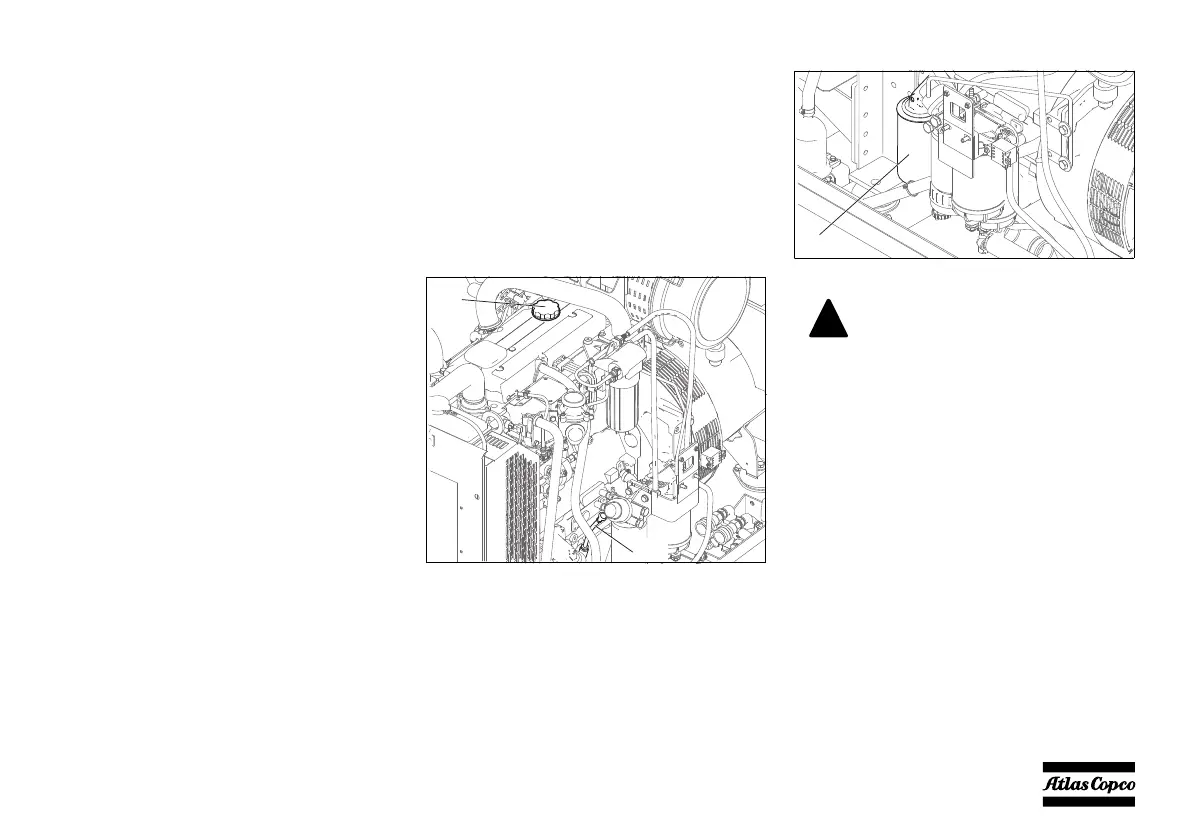

5.4.2 Engine oil and oil filter change

Replacing the oil filter element

– Place an appropriate drain pan under the oil drain

flexible.

– Remove the drain plug from the oil drain flexible

to drain the oil.

– Replace the seal of the drain plug.

– Install and thighten the drain plug on the oil drain

flexible.

– Unscrew the oil filter element (OF) from the

adapter head.

Observe all relevant environmental

and safety precautions.

Loading...

Loading...