- 57 -

If a battery does not need any make-up water at all

over a considerable time of operation, an

undercharged battery condition may be caused by

poor cable connections or a too low voltage regulator

setting.

5.5.3.5 Periodic battery service

– Keep the battery clean and dry.

– Keep the electrolyte level at 10 to 15 mm above

the plates or at the indicated level; top up with

distilled water only. Never overfill, as this will

cause poor performance and excessive corrosion.

– Record the quantity of distilled water added.

– Keep the terminals and clamps tight, clean, and

lightly covered with petroleum jelly.

– Carry out periodic condition tests. Test intervals

of 1 to 3 months, depending on climate and

operating conditions, are recommended.

– If doubtful conditions are noticed or malfunctions

arise, keep in mind that the cause may be in the

electrical system, e.g. loose terminals, voltage

regulator maladjusted, poor performance of

generator, etc...

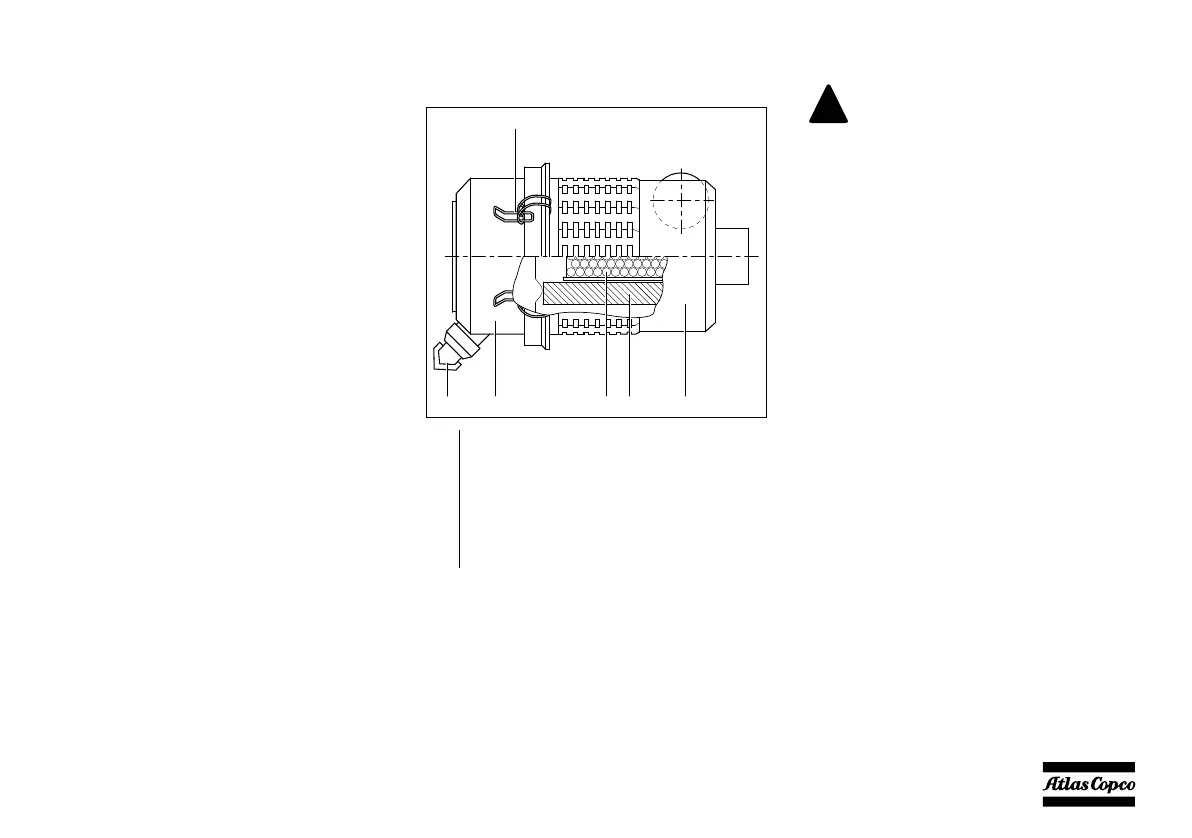

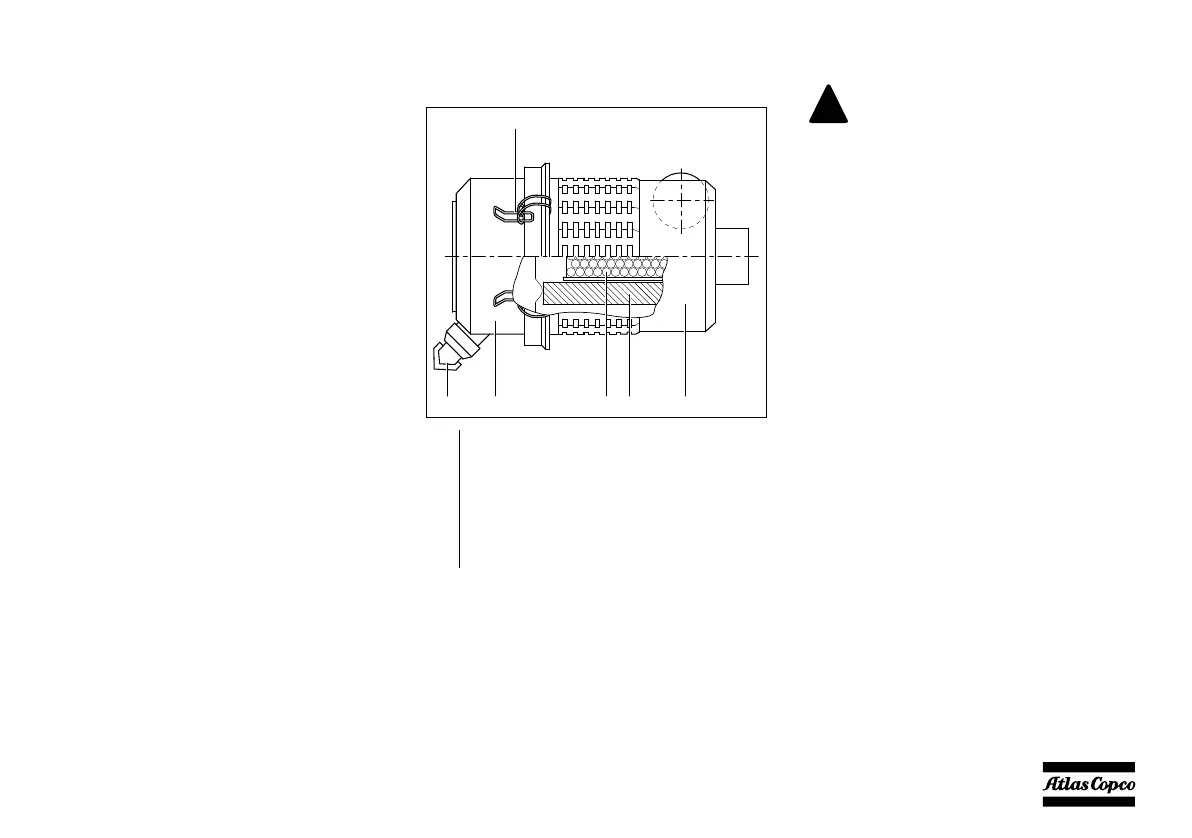

5.5.4 Servicing air filter engine

5.5.4.1 Main parts

5.5.4.2 Recommendation

– New elements must also be inspected for tears or

punctures before installation.

– Discard the filter element (4) when damaged.

– In heavy duty applications it is recommended to

install a safety cartridge which can be ordered

with part no.: 2914 9307 00.

– A dirty safety cartridge (3) is an indication of a

malfunctioning air filter element (4). Replace the

element and the safety cartridge in this case.

– The safety cartridge (3) cannot be cleaned.

5.5.4.3 Cleaning the dust trap

To remove dust from the dust trap (2), clean it with a

dry rag.

1 Snap clips

2Dust trap

3 Safety cartridge

4 Filter element

5 Filter housing

6 Dust evacuator

The Atlas Copco air filters are

specially designed for the

application. The use of non-genuine

air filters may lead to severe

damage of engine and/or alternator.

Never run the generator without air

filter element.

Loading...

Loading...