What to do if my Autotrol Control Unit displays ERR 1?

- RriveragregorySep 14, 2025

If your Autotrol Control Unit displays ERR 1, it indicates that the program settings have been corrupted. Press any key and reprogram Level I settings.

Loading...

Loading...

What to do if my Autotrol Control Unit displays ERR 1?

If your Autotrol Control Unit displays ERR 1, it indicates that the program settings have been corrupted. Press any key and reprogram Level I settings.

What to do if my Autotrol Control Unit runs out of conditioned water too quickly?

If you run out of conditioned water between regenerations with your Autotrol Control Unit: * Repeat regeneration. * Reset the control and program the resin volume to the correct setting.

| Model | Logix 764 |

|---|---|

| Type | Control Unit |

| Control Type | Electronic |

| Power Supply | 24V AC/DC |

| Flow Rate | Up to 20 GPM |

| Timer Type | Digital |

| Display | LCD |

| Operating Pressure | 20-125 PSI |

| Programs | Multiple |

| Cycle Length | Adjustable |

| Application | Water Treatment |

| Output Voltage | 24V |

| Valve Connection | NPT |

| Programming | User-friendly interface |

| Operating Temperature | 34°F to 120°F |

| Backup Battery | Yes |

| Mounting | Wall Mount |

Explains icons used in the manual for warnings and hints.

Guidelines for choosing a suitable location for the water conditioning system.

Instructions for connecting the water supply lines to the system.

Procedures for connecting the drain line for waste water discharge.

How to connect the overflow line to prevent spills and water damage.

Information on brine tank requirements and salt usage.

Identifies the locations and functions of valve discs within the system.

Overview of the Logix 764 controller's operational features and memory.

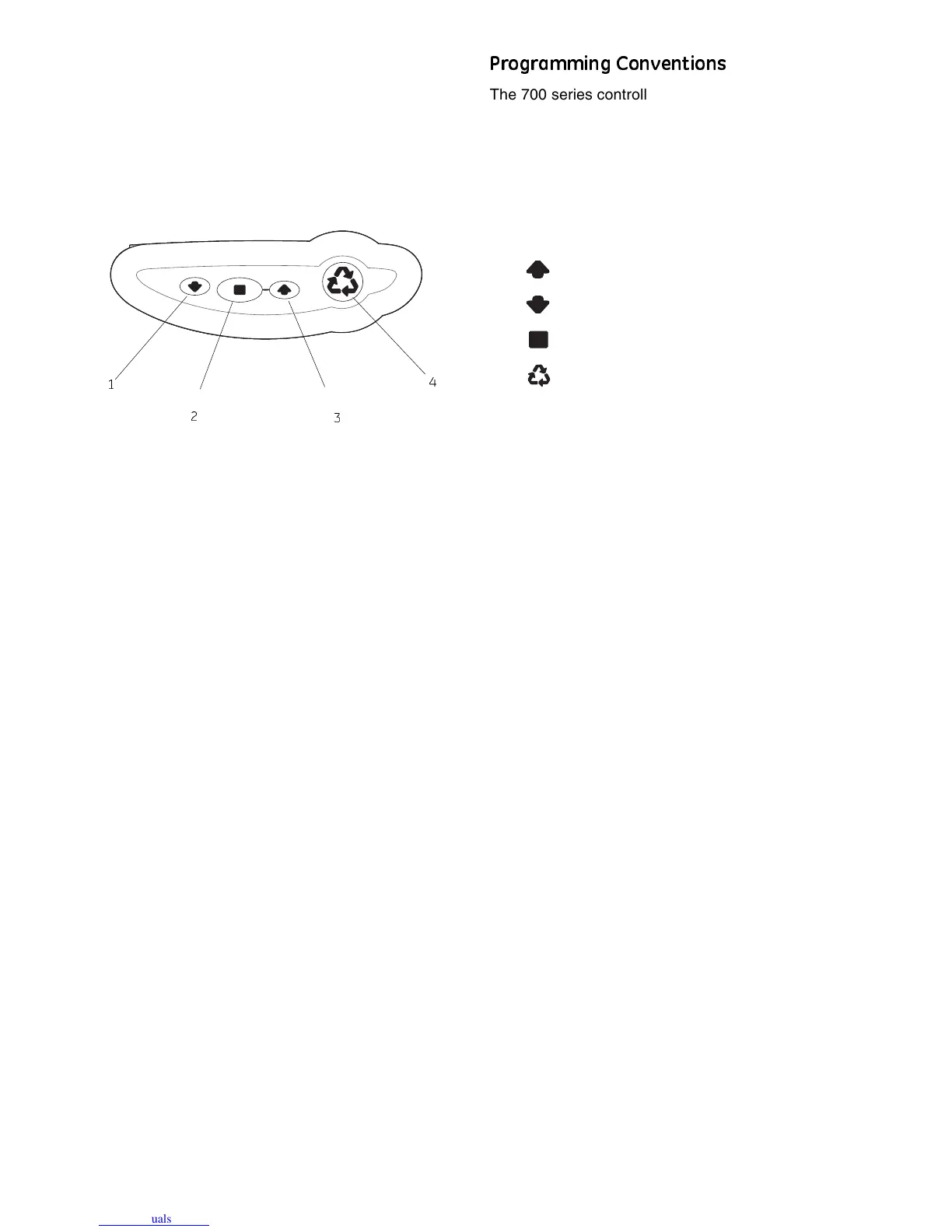

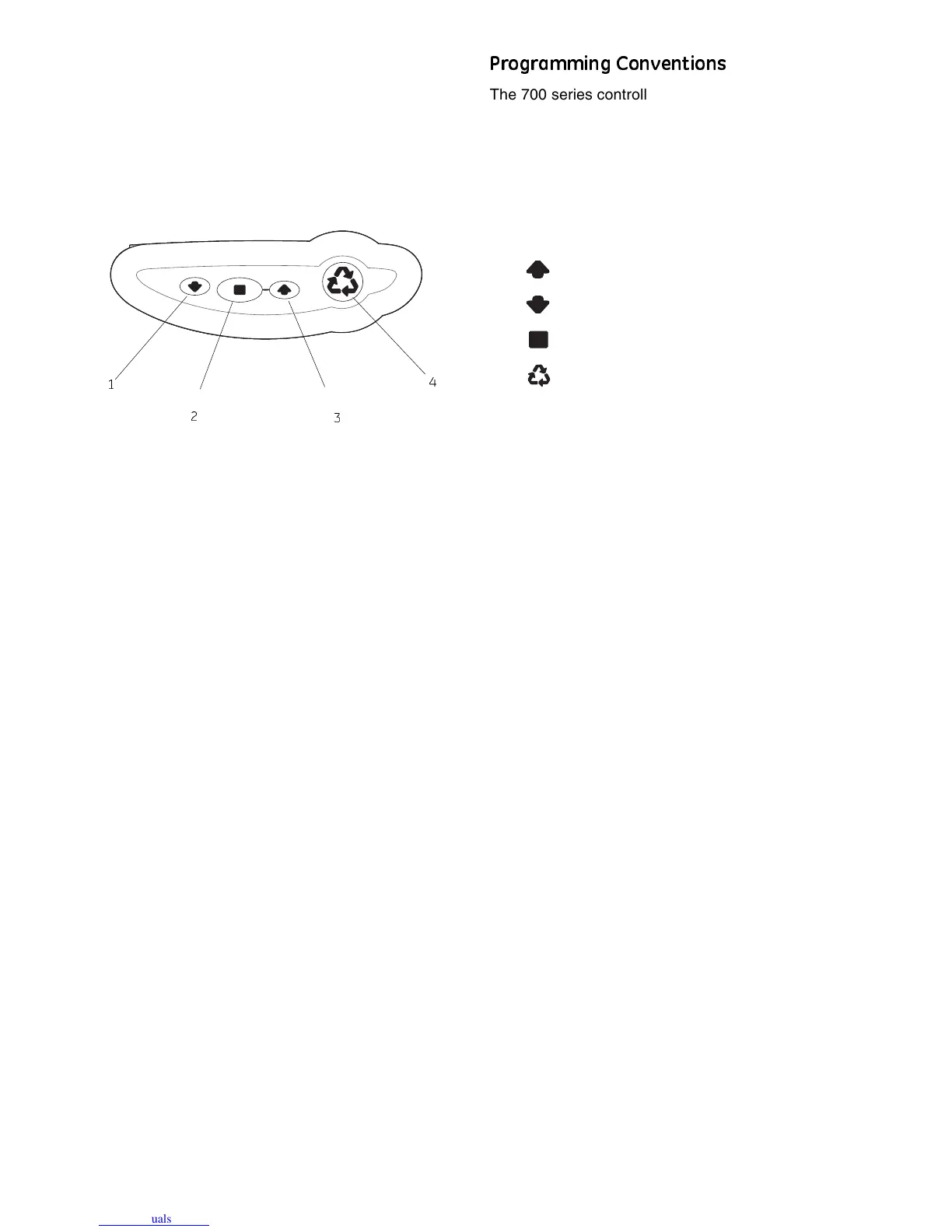

Explains the methods and symbols used for programming the controller.

Specific steps to bring an alternating system into initial operation.

Describes the different programming levels available for system customization.

Guide to programming the control for normal applications.

Allows selection of when the refill cycle occurs, enabling a "dry" brine tank.

Initiates a manual regeneration that starts at the programmed time of day.

Starts a manual regeneration immediately when the button is pressed.

Programs a second regeneration to occur at a later programmed time.

Initiates two manual regenerations back-to-back.

Outlines standard connections for twin unit parallel and alternating configurations.

Provides an exploded view and a list of parts for the 255 valve.

Addresses error codes and the check salt light for the 764 controller.