microLAN b.v. BACTcontrol – User Manual – V0.4.4 Page 19 of 59

9 Ventilator

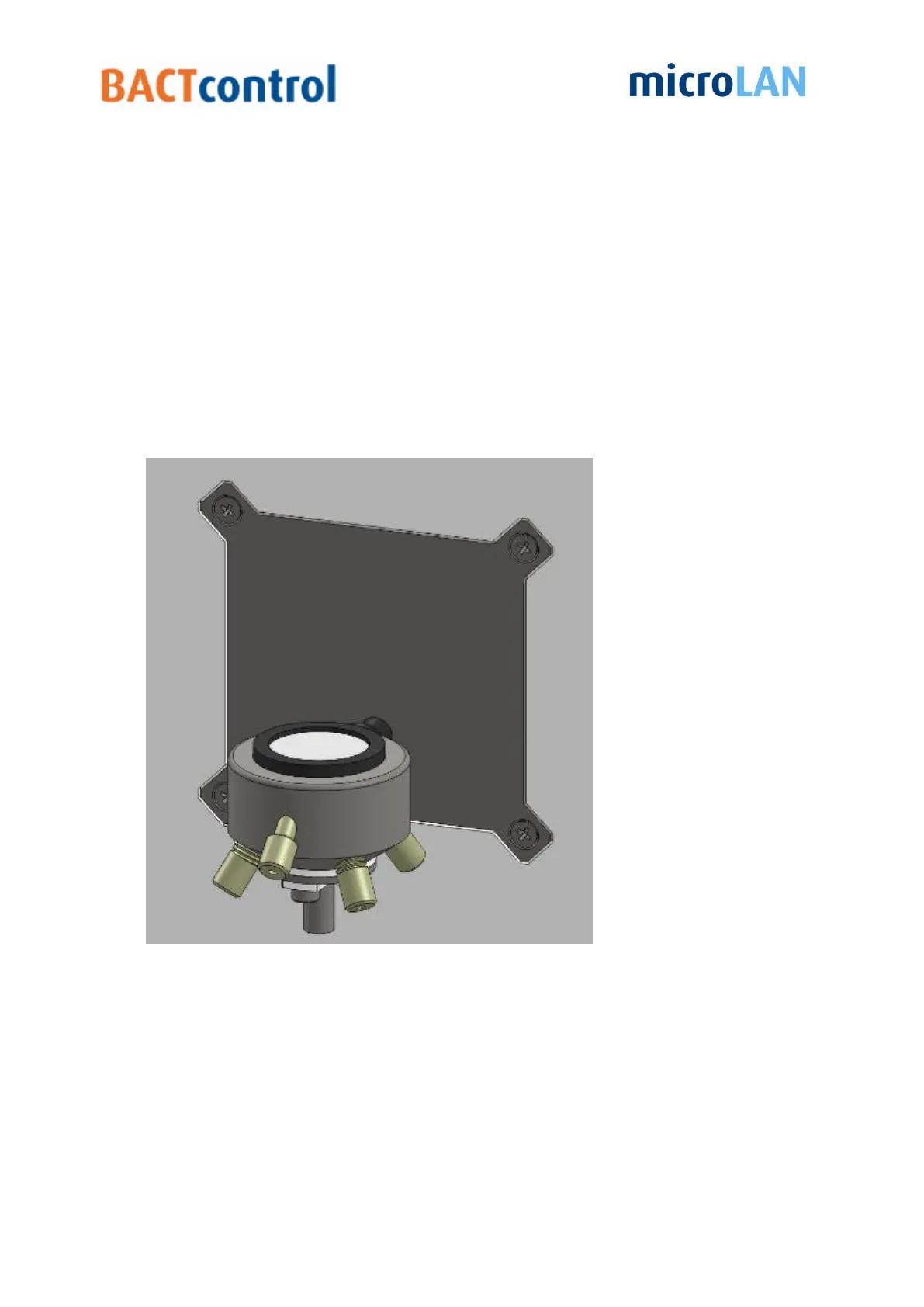

5.2 REACTION CHAMBER

In the reaction chamber the measurements take place. When the concentration of

bacteria in the sample is low, the bacteria has to be concentrated in order to be able

to detect the fluorescence and have reliable results. This is done with a porous

ceramic filter (Figure 9). The sample is pumped into the reaction chamber and flows

through the ceramic filter (size 0,45 µm). The pores of the filter are small enough to

retain the bacteria and let the water flow through. When the concentration of bacteria

is high enough and there is no need to concentrate it, the dummy filter can be used

instead of the ceramic filter. The dummy filter is made from metal, so liquid cannot

flow through it. In this case the sample will be pumped to the reaction chamber and a

valve is kept open in order to let the first millilitres of sample flow through the outlet,

increasing the chance that a representative sample will be measured. When the

chamber is filled the measurement takes place.

Figure 9 Reaction chamber with ceramic filter with C-ring

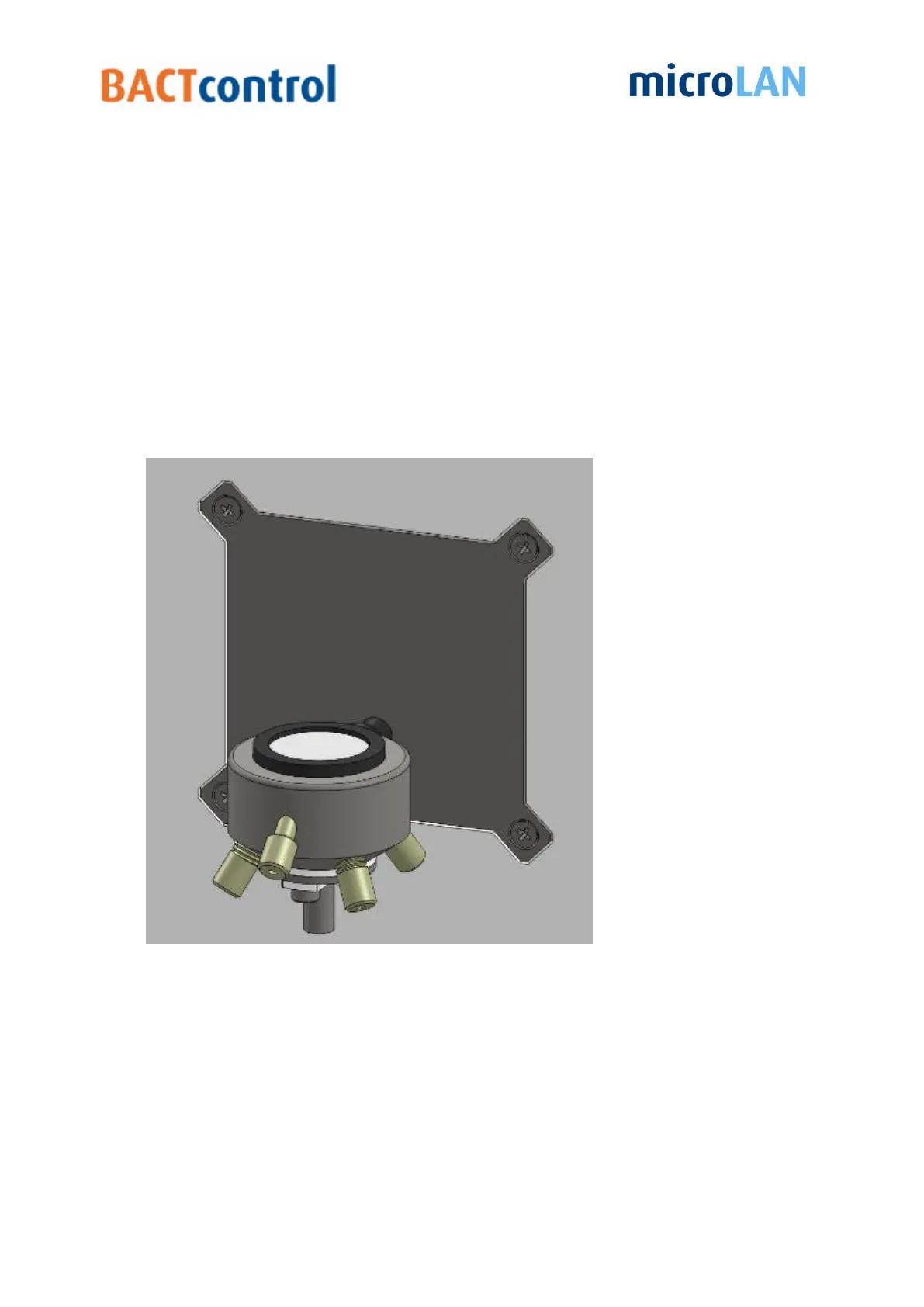

After the sample has been heated up to the right temperature, the photodiode emits

light with a wavelength of 366 nm through the photodiode window into the reaction

chamber (Figure 10). As the bacteria to be determined is present in the sample, the

hydrolysed MU substrate will fluorescence (APPENDIX A: GENERAL WORKING OF

THE BACTCONTROL).

The fluorescence is detected by the photodiode and converted into enzymatic activity

and expressed in picomole per minute

Loading...

Loading...