BA_373-E07_04_DEF_MJ_1821

35 | 36W. Baelz & Sohn GmbH & Co. · Koepstrasse 5 · 74076 Heilbronn · Germany · www.baelz.de Seite | Page

Motorized Linear Actuator baelz 373-E07

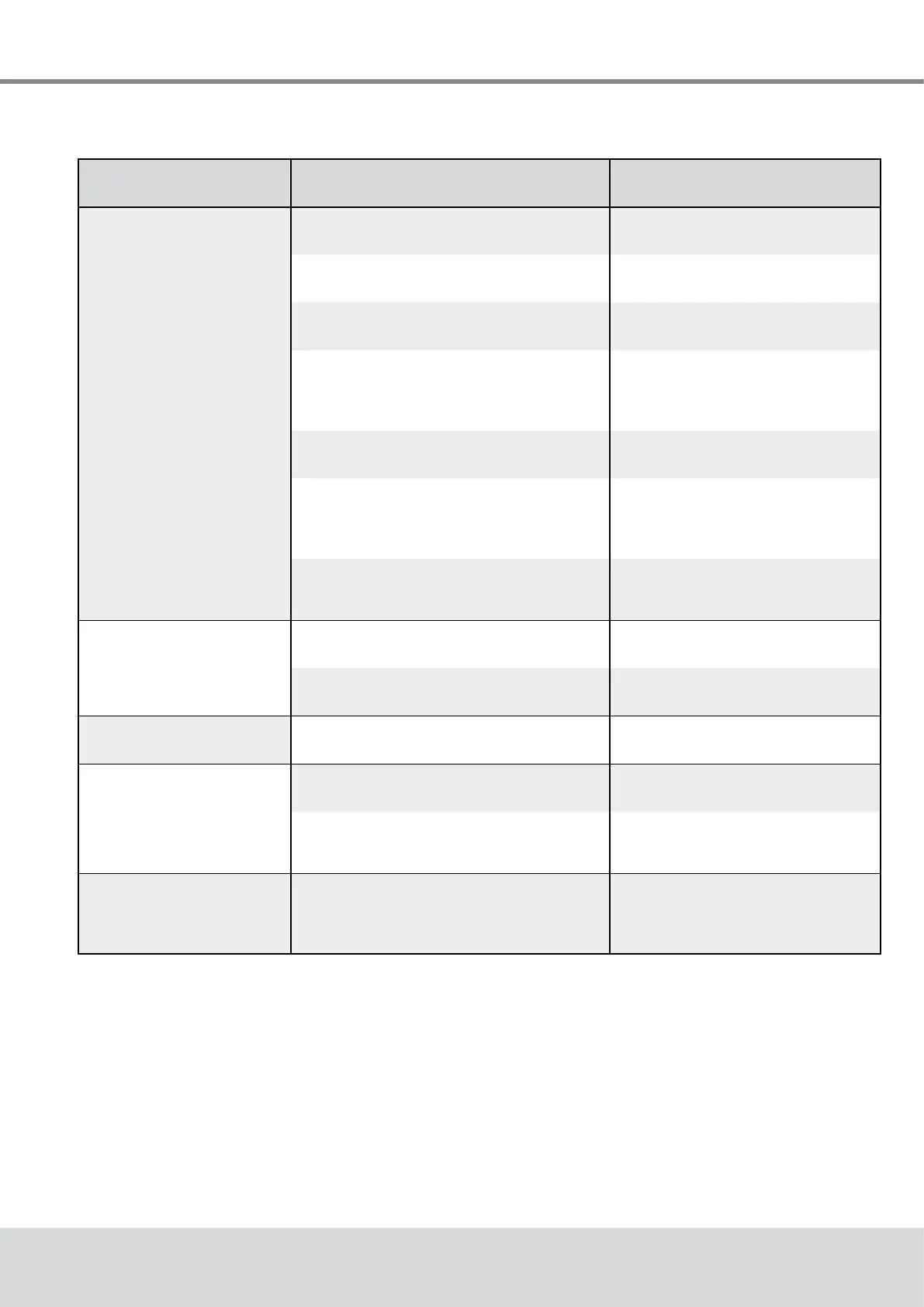

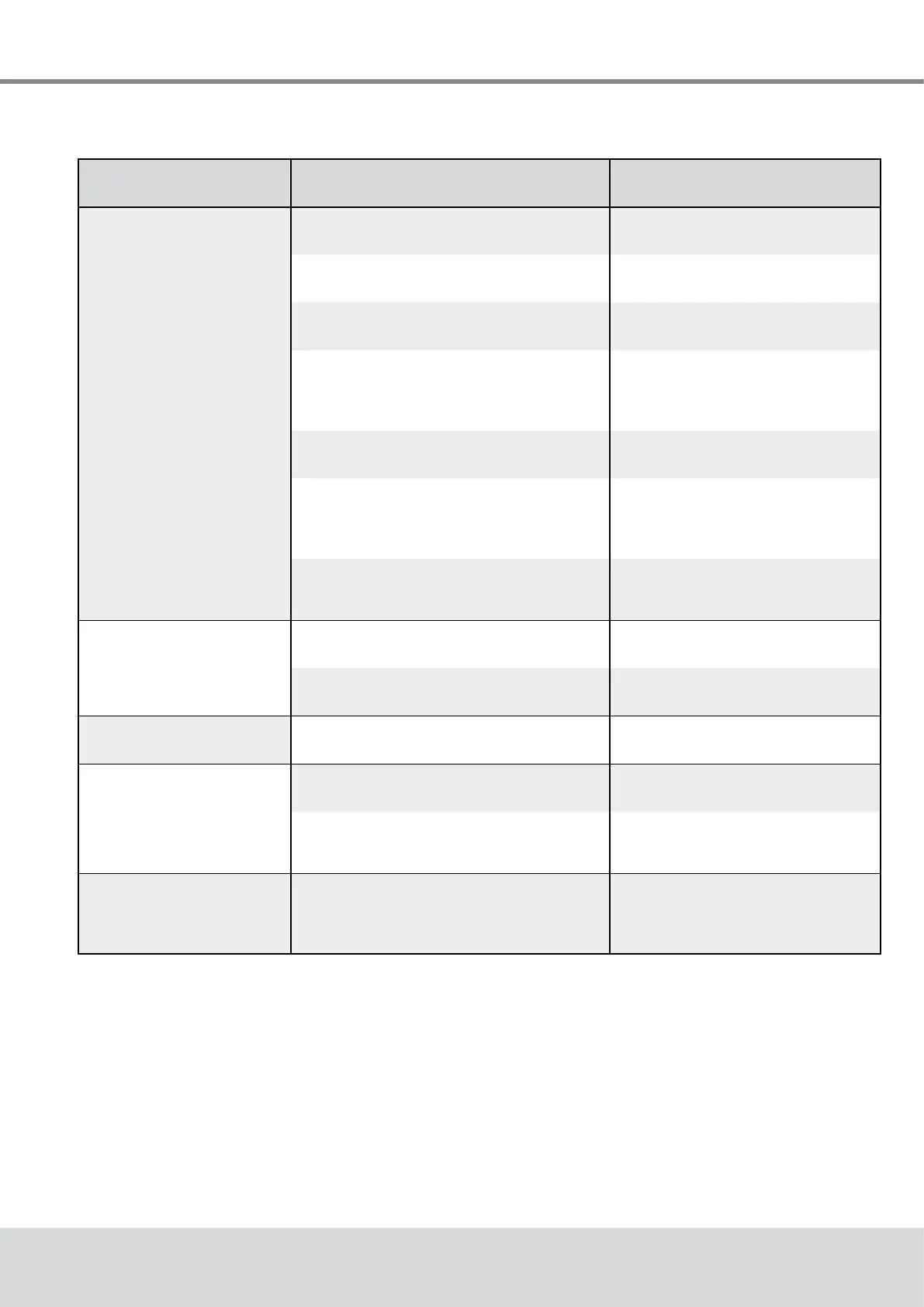

Malfunction Cause Action required

Actuator not working

Power failure Determine the cause and correct the

problem.

Defective fuse (in control cabinet) Determine the cause and correct the

problem, replace the fuse.

Linear actuator incorrectly connected Re-connectasspeciedoncircuit

diagram (inside cover).

Short circuit caused by humidity Determine the cause, dry the linear

actuator; if necessary, replace cover

sealandscrewsand/ortprotective

cover.

Short circuit caused by incorrect connection Connect correctly.

Motor winding damage caused, for example,

by high voltage or defective electronics

Determine cause, measure current

data, compare with nameplate and

specications,dismantlelinear

actuator and return for repair.

Voltage drop due to connecting cables being

toolongand/orhavinginsucientcross-

section

Measure current data with linear

actuator, recalculate connecting

cables and replace as necessary.

Actuator running erratically,

constantly opening and

closing

Poweructuationsexceedpermissible

tolerance

Improve power supply conditions.

Loose contact in supply line Check and tighten connections

(terminal blocks).

Actuator stops intermittently

Valve jamming Enable smooth valve movement.

Actuator does not move to

end position. Valve fails to

open / close

System pressure too high Adjust system pressure.

Poor input signal

- interfering signals

-signaluctuation

Check input signal at linear actuator,

correct the problem causing the

malfunction.

Linear actuator fails to move

or does not move correctly

tothepositiondenedby

the input signal.

Circuit board defective Replace circuit board, if necessary

dismantle actuator and return for

repair.

10.1 Checklist for operational malfunctions

Loading...

Loading...